Fully closed compressor with inward convex exhaust pipe insert opening

A fully enclosed and exhaust pipe technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problem of high material costs and achieve the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

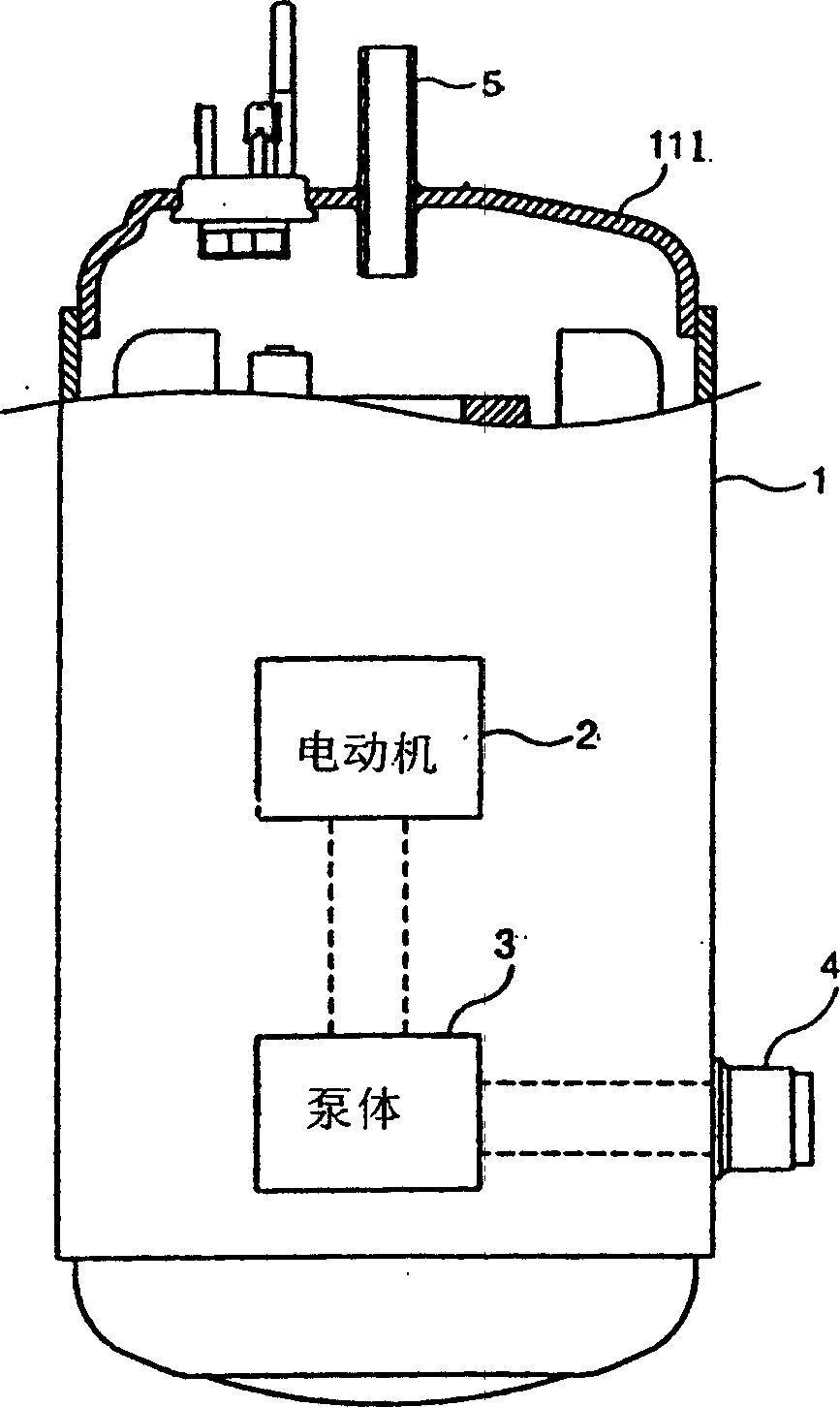

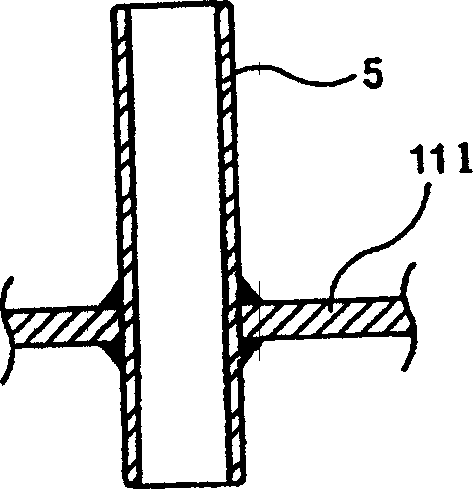

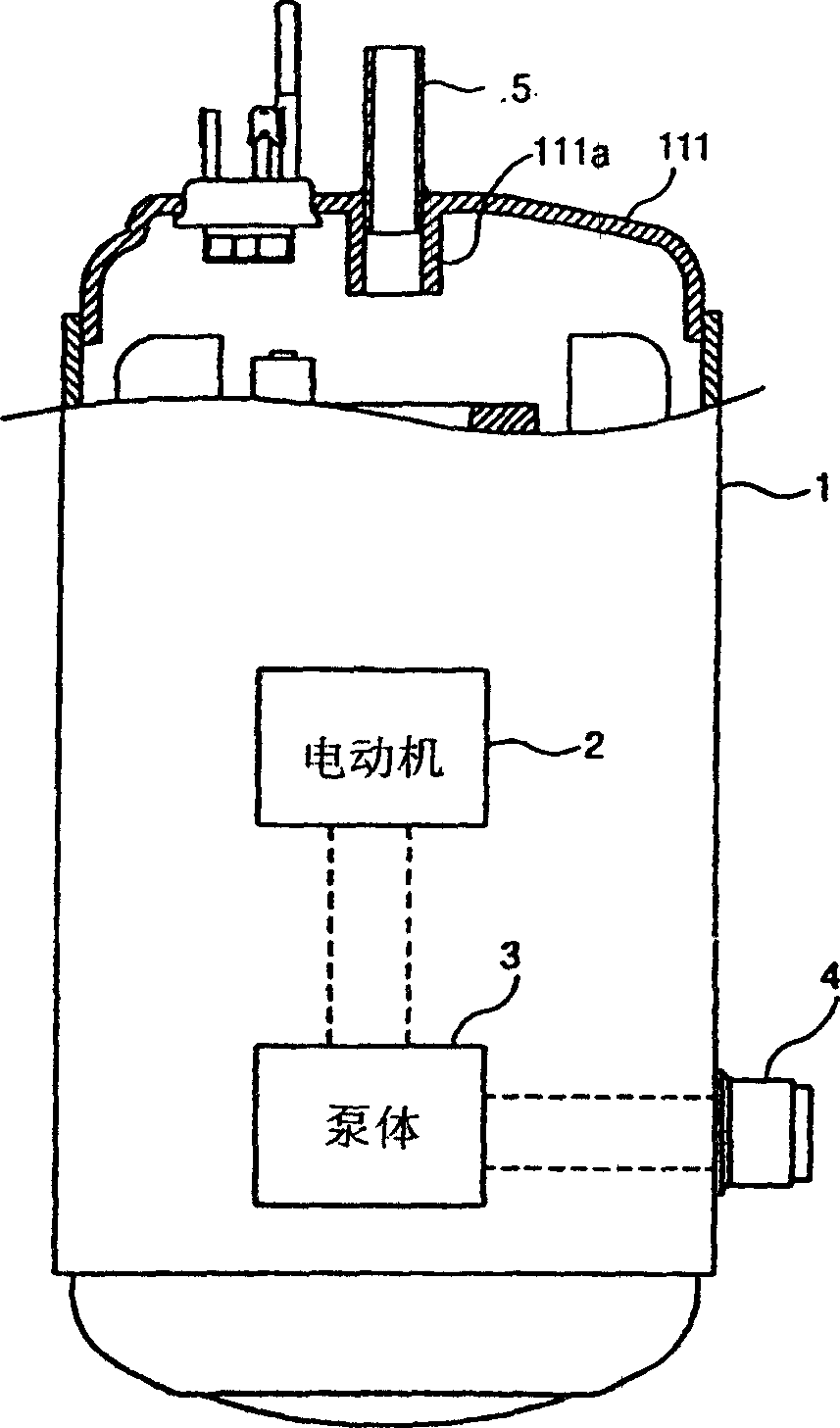

[0015] Such as image 3 , Figure 4 As shown, the fully enclosed compressor with the exhaust pipe insertion port protruding inward in the present invention is composed of a closed container 1, a motor 2, a pump body 3, an air suction pipe 4, and an exhaust pipe 5; the closed container 1 The motor 2 and the pump body 3 are installed inside, and the motor 2 and the pump body 3 are fixed inside the airtight container 4 by pressing and welding; the suction pipe 4 for inhaling cold air passes through the shell of the airtight container 1 and is connected with the pump body 3 , the other side of the suction pipe 4 is connected with the evaporator (not shown in the figure), and the suction pipe 4 plays the role of sucking gas inside the compressor; The exhaust pipe 5 of discharge joins with the loam cake 111 of airtight container 1, and the other side of exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com