Small displacement sensing method and device

A sensing method and technology of small displacement, applied in the direction of measuring device, using electric device, electromagnetic measuring device, etc., can solve the problems of difficult industrial manufacturing, cannot be made too small, small size of the sensor, etc., to facilitate industrial implementation, The materials are easy to obtain and the effect of the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

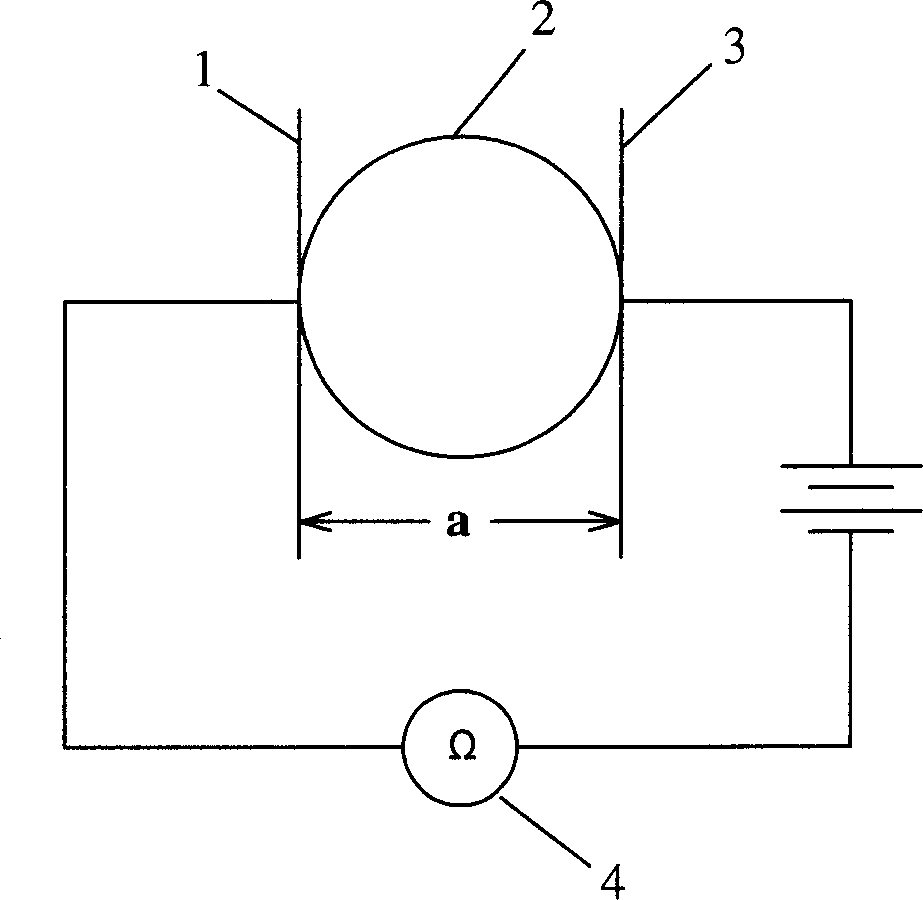

[0021] See figure 1 A deformation medium 3 with a certain resistance value is defined between the two conductors 1 and 2. The deformation medium 3 can be a liquid or colloidal medium, or other media that can deform, such as a sponge with resistance value bodies or other deformable media. The volume size of the deformable medium 3 changes with the change of the measured displacement, resulting in a change in the resistance value of the deformable medium 3, and measuring the change in the resistance value of the deformable medium between two conductors can obtain the measured value. Measure displacement parameters. The two conductors 1 and 2 can be flat electrodes with a certain area, and the other surfaces of the two electrode plates 1 and 2 are electrically connected with a resistance measuring device 4 . The measured displacement is the longitudinal distance a between the two conductors in this embodiment, and the change of the longitudinal distance a between the two conduc...

Embodiment 2

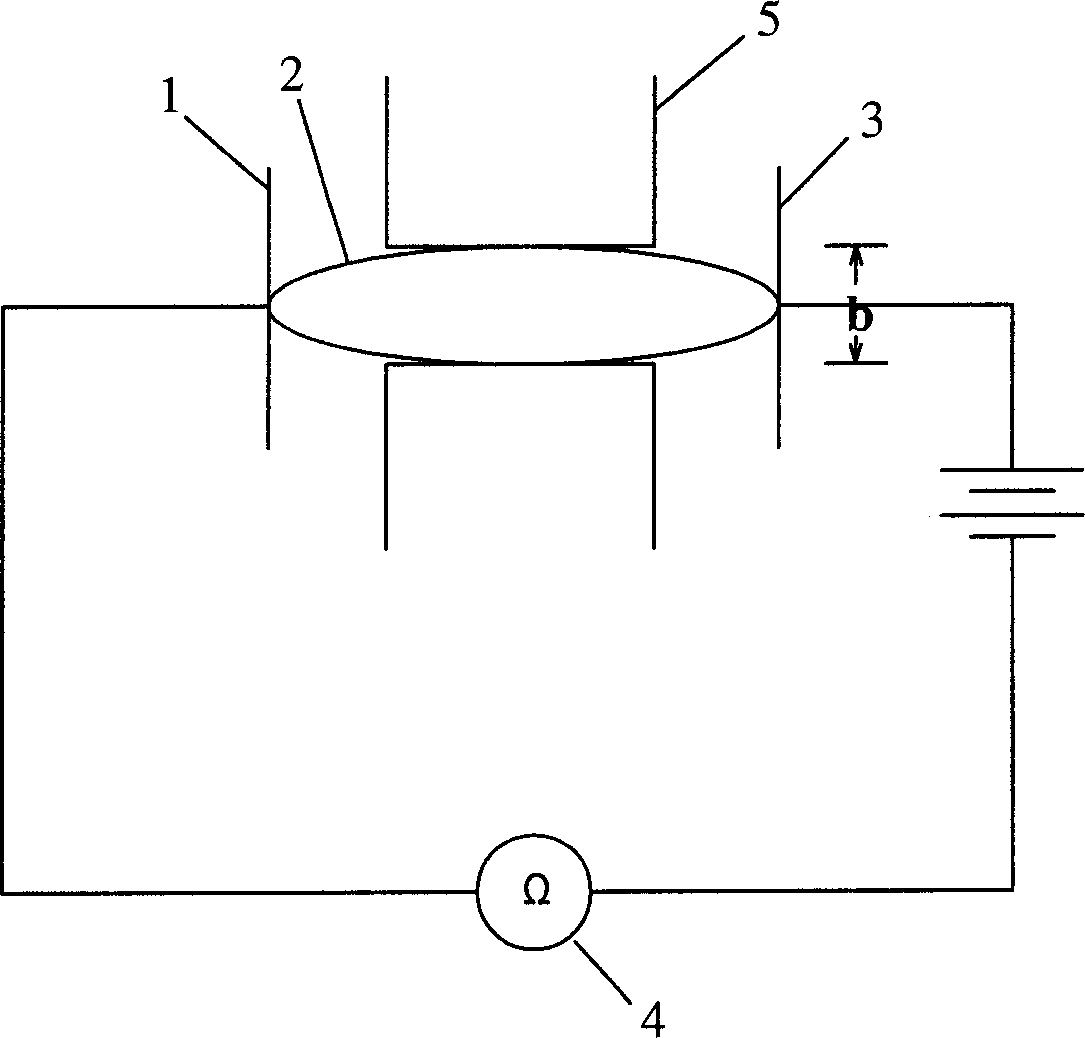

[0024] See figure 2 , The outer surface of the deformable medium 3 between the two electrode plates 1, 2 may be provided with a restricting piece 5, which in this embodiment is two restricting blocks 5, and the restricting block 5 is an insulator. The material selection and limitation of the deformable medium 3 are the same as those in Example 1, except that the measured displacement is the transverse direction between the two limiting blocks arranged between the two conductors 1 and 2 to limit the radial displacement of the deformable medium 3. distance b. The change of the lateral distance between the two limiting blocks 5 causes the cross-sectional area of the deformable medium 3 resistor between the electrodes to change, which in turn causes the resistance value to change inversely proportional to the lateral distance, see the calculation formula of embodiment 1 (the present embodiment The lateral distance b may be the lateral distance S) in the formula. The measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com