Safety presure cooker

A pressure cooker and safe technology, applied in pressure cookers, cooking utensils, household appliances, etc., can solve the problems of insufficient elastic displacement, high consumables, and inconvenient integrated design of the whole machine, and achieve the effect of solving the problem of safe pressure relief.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

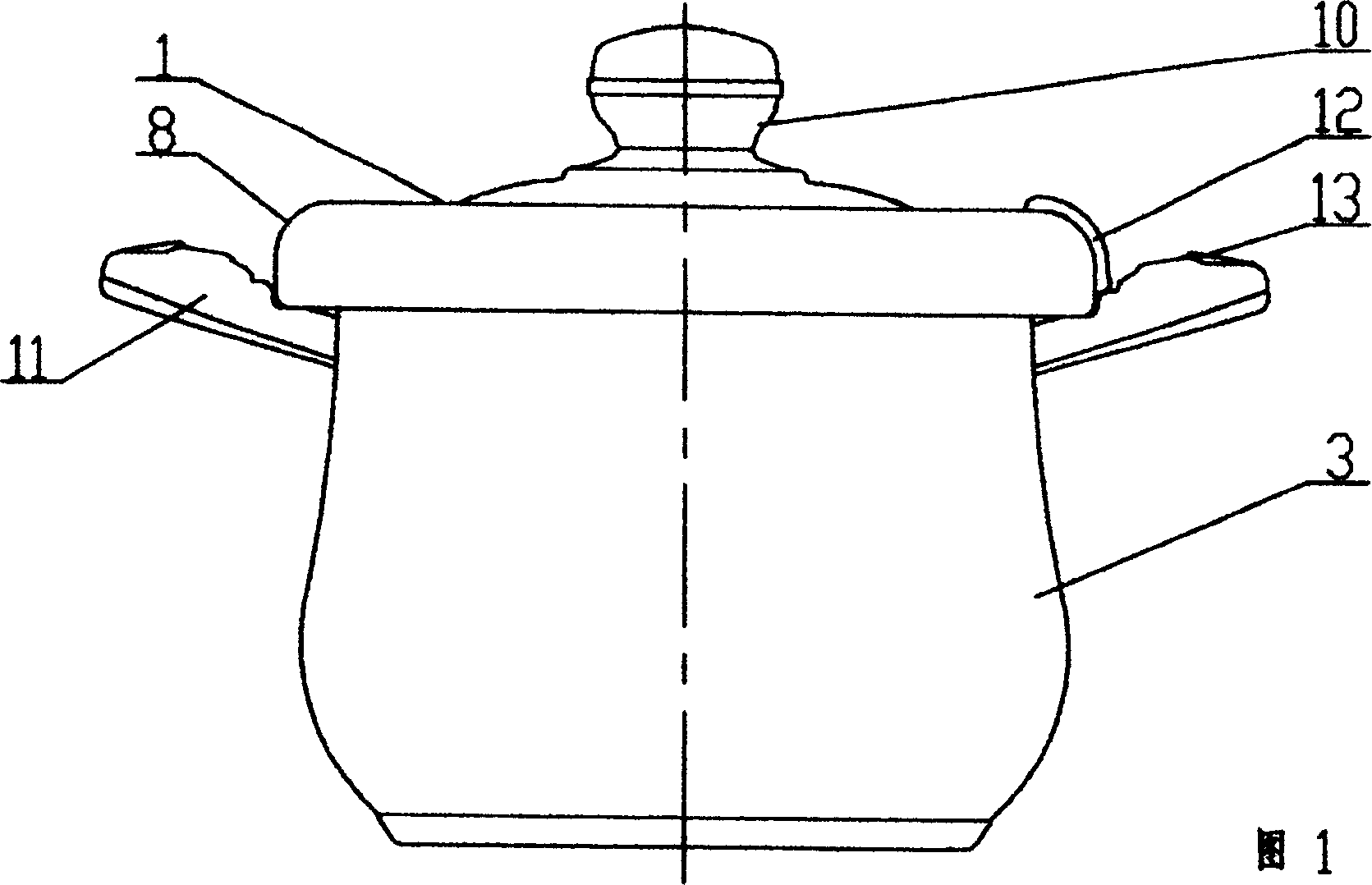

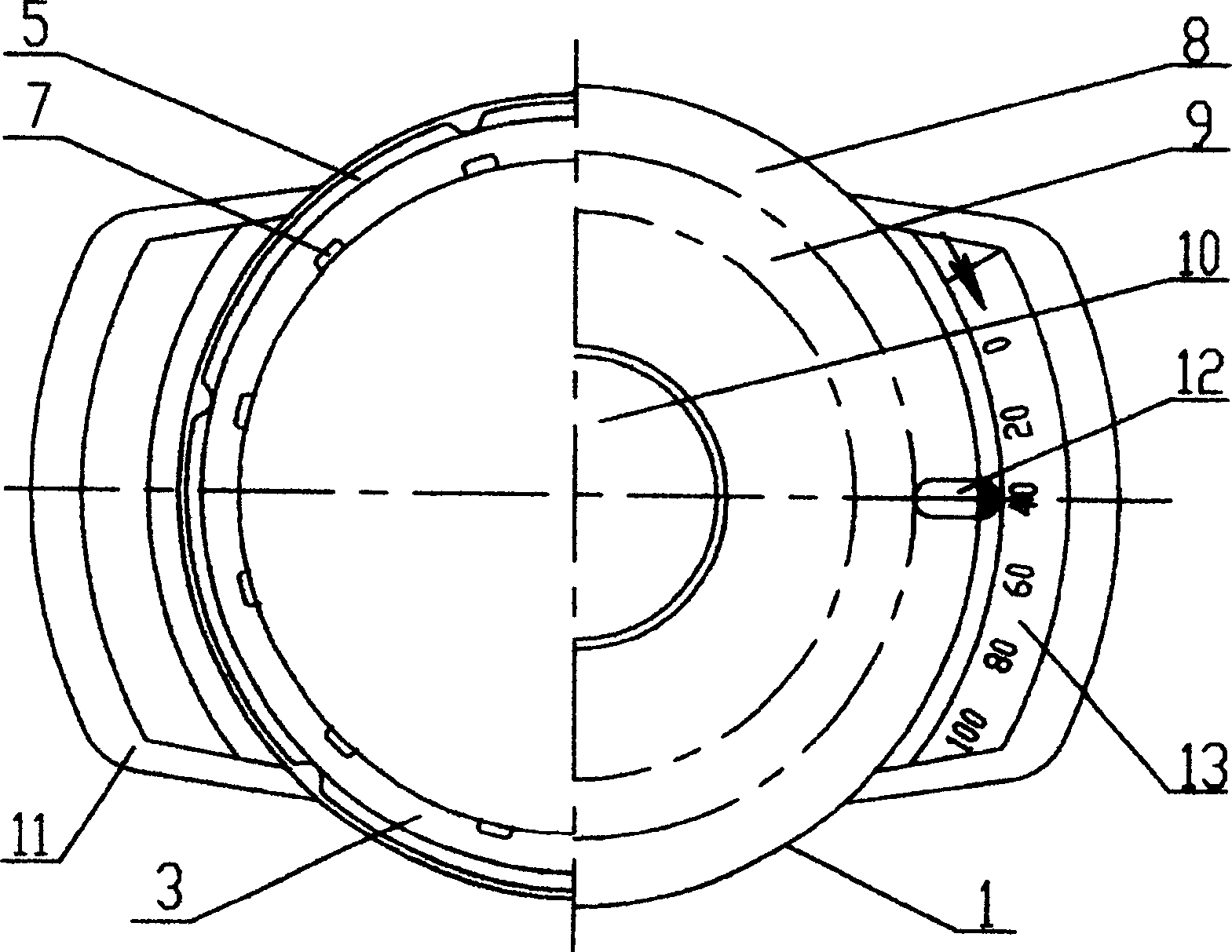

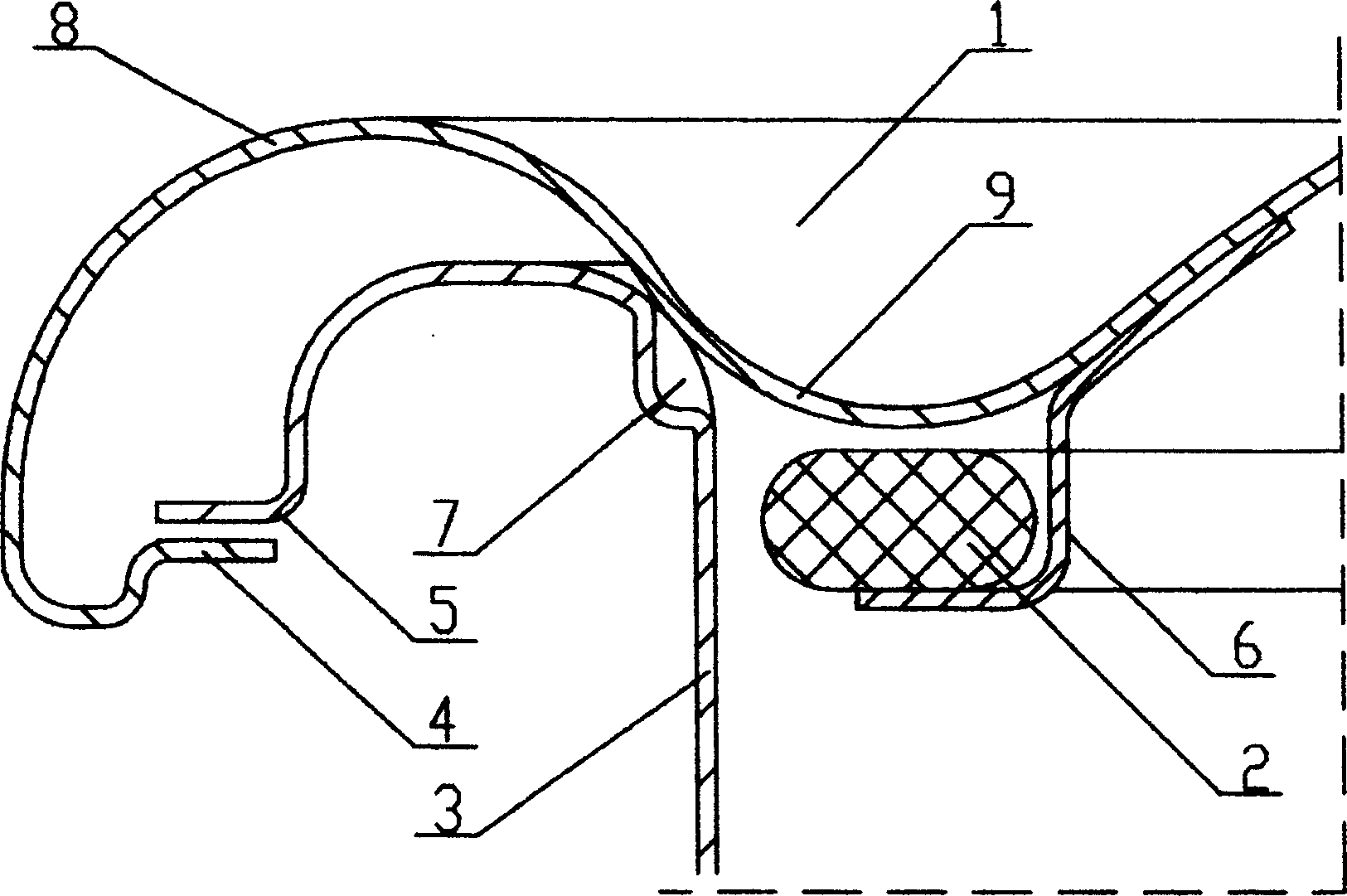

[0030] Embodiment 1. In this example, the inner diameter of the mouth of the pot body 3 is 21 cm and the maximum working pressure in the pot is 100 kPa as an example. The pot cover 1 is made of a stainless steel plate with good elasticity and a thickness of about 0.8mm, and its maximum outer diameter is selected at about 26.5cm——to form a large-diameter pot cover 1, the radius of its edge corrugation 8 is selected at about R16mm, and the concave corrugation The radius of 9 is selected around R12mm, the corrugation depth of concave corrugation 9 is selected around 12mm, and the transition between edge corrugation 8 and concave corrugation 9 is smooth. Its geometric dimension of the hard center of pot cover 1 is related to the design requirements of the whole and appearance. In the present embodiment, the pot lid button 10 is arranged on a plane with a diameter of about 10 cm in the hard center of the pot lid 1, and the plane is higher than the top of the edge corrugation 8 by a...

Embodiment 2

[0032] Embodiment 2, this example is example with pot body 3 inner diameters 19cm, and pot cover 1 selects good elasticity, and thickness is the stainless steel plate making of about 0.7mm for use, and its maximum external diameter is selected at about 24cm, or the large pot cover 1 shape. The difference from Example 1 is that the pot lid teeth 4 of the pot lid 1 need to be turned over by using the curling process in the existing patented technology, and the number of the pot lid teeth 4 is selected as 5, so as to increase the closure of the lid Select the angle of pressure. At the same time, the pot body teeth 5 of the pot body 3 should also be consistent with parameters such as the chord length and the lift angle of the pot lid teeth 4. The remaining parameters of embodiment 2 can refer to embodiment 1.

Embodiment 3

[0033] Embodiment 3. This embodiment is based on Embodiment 1 and Embodiment 2. The pot body 3 is made of an aluminum plate with a thickness of about 2.5 mm to form a product type of a stainless steel pot cover 1 and an aluminum pot body 3 . Wherein, the thickness of the aluminum plate for making the pot body 3 matched with embodiment 1 is slightly thicker, while the thickness of the aluminum plate for making the pot body 3 matched with embodiment 2 is slightly thinner, and the pot body 3 can also adopt thinning stretching, pot body expansion, etc. Craftsmanship, strive to match with pot cover 1. For the remaining parameters of this embodiment, reference may be made to Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com