Nano granules of ampyhiphilic three block copolymer preparation method and application

A tri-block and copolymer technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., to achieve the effects of improving bioavailability, prolonging cycle time, and eliminating the effect of burst release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

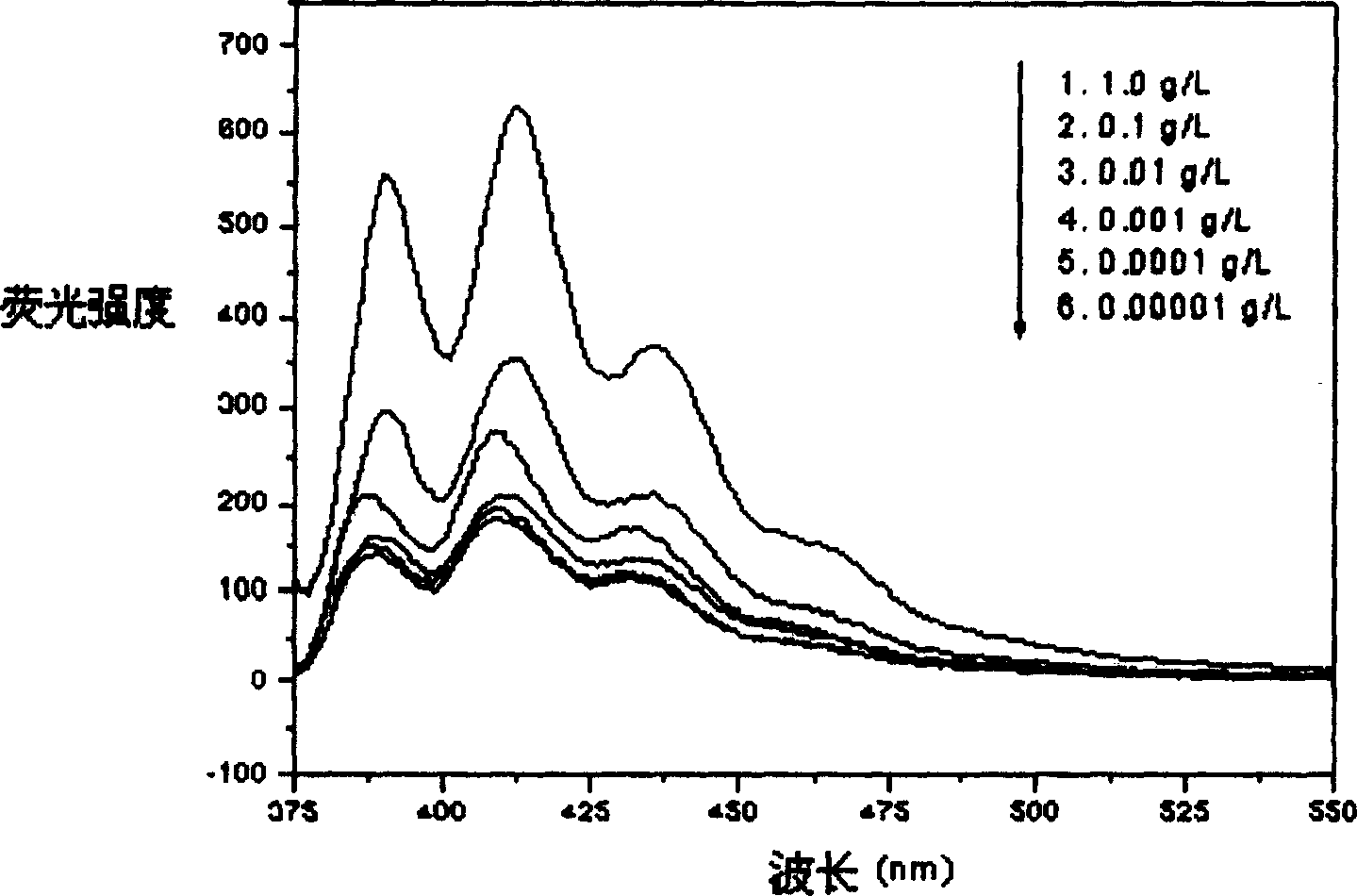

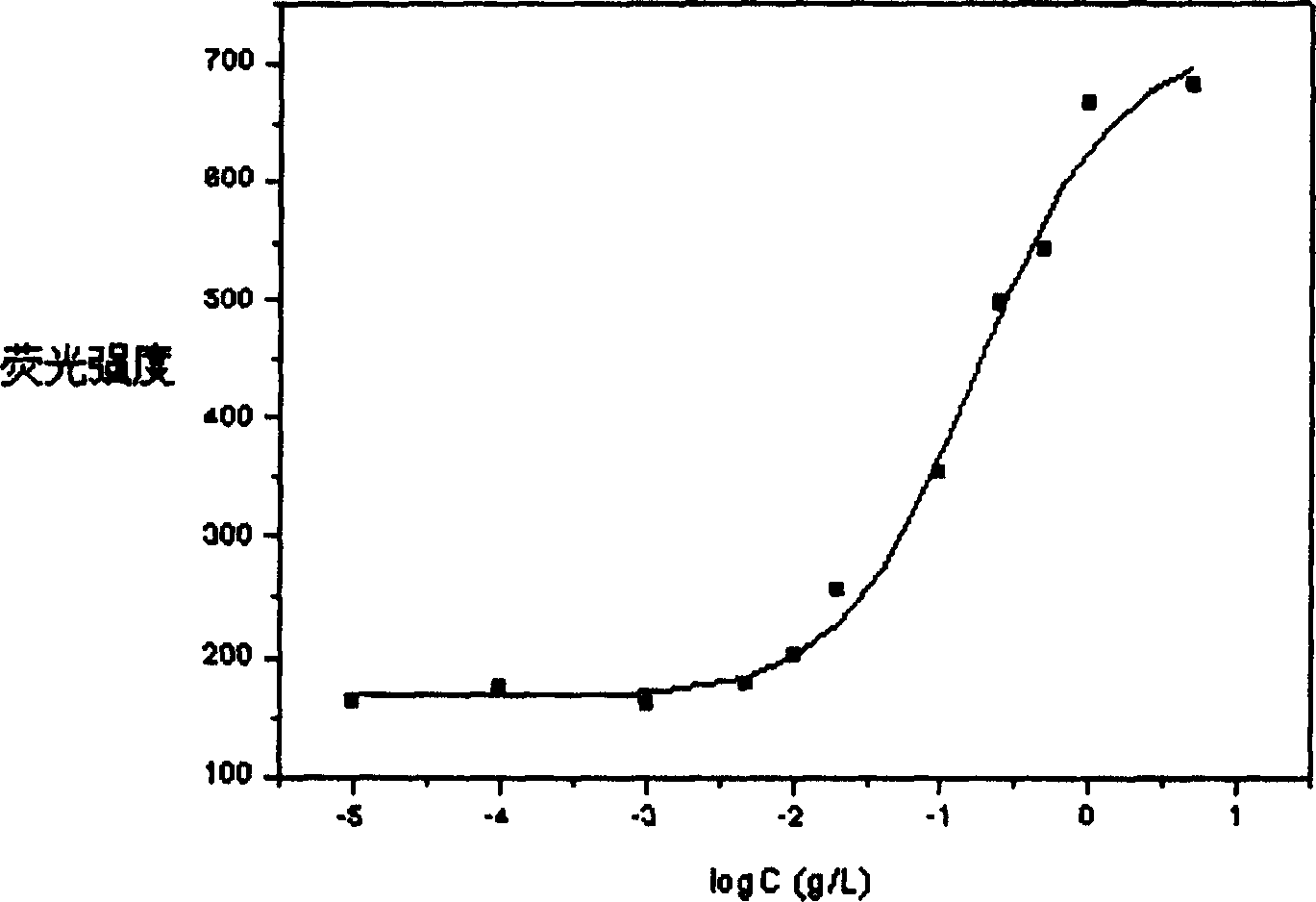

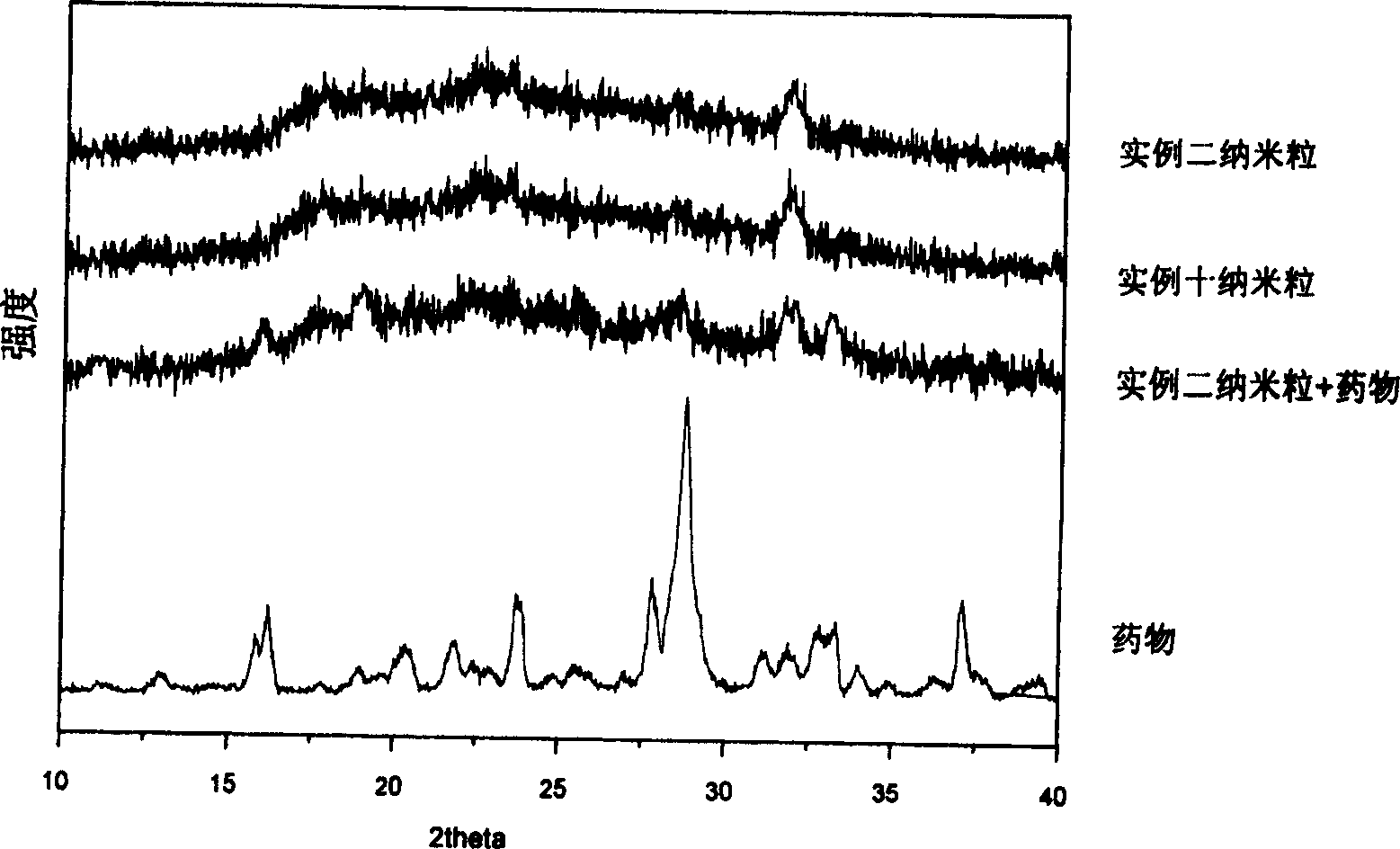

Method used

Image

Examples

Embodiment 1

[0040] Preparation of Amphiphilic Triblock Copolymer: Weigh 0.0264 g of polyethylene glycol (molecular weight 6000) and 0.2890 g of 5,5-dimethyl-trimethylene carbonate into a silylated, dry polymerization tube , and then the 0.1% molar ratio of stannous isooctanoate anhydrous toluene solution was moved into the polymerization tube through a syringe, and the system was subjected to vacuum-puffing nitrogen process repeated 3 times to remove the solvent, vacuum-sealed the tube, and put it into 150 ℃ constant temperature oil The reaction was carried out in the bath for 16 hours. After the reaction, the obtained polymer was dissolved in dichloromethane and poured into methanol for reprecipitation. The polymer was vacuum-dried at 40°C to obtain a white solid, which was an amphiphilic triblock copolymer. The yield was 81.7%, the number-average molecular weight was 74,000, and the polydispersity index was 1.44.

[0041] 10 mg of the above amphiphilic triblock copolymer was weighed a...

Embodiment 2

[0043]Weigh 0.0564 gram of polyethylene glycol (molecular weight is 6000) and 0.2848 gram of 5,5-dimethyl-trimethylene carbonate and join in the drying polymerization tube of silanization treatment, then add 0.1% molar ratio isooctanoic acid The tin anhydrous toluene solution was transferred into the polymerization tube through a syringe, and the system was vacuum-filled with nitrogen three times to remove the solvent, and the tube was vacuum-sealed, and then placed in a constant temperature oil bath at 150°C for 16 hours to react. After the reaction, the obtained polymer was dissolved in a small amount of dichloromethane, poured into a large amount of methanol for reprecipitation. The polymer was vacuum-dried at 40°C to obtain a white solid which was the amphiphilic tri-block copolymer. The yield is 50.9%, the number average molecular weight is 33000, and the polydispersity index is 1.37.

[0044] Weigh 10 mg of the above-mentioned amphiphilic tri-block copolymer dissolved i...

Embodiment 3

[0046] Weigh 0.1295 gram of polyethylene glycol (molecular weight is 6000) and 0.3022 gram of 5,5-dimethyl-trimethylene carbonate and join in the dry polymerization tube of silanization treatment, then add the isooctanoic acid of 0.1% molar ratio The stannous anhydrous toluene solution was transferred into the polymerization tube through a syringe, and the system was vacuum-filled with nitrogen for 3 times to remove the solvent, and the tube was vacuum-sealed, and the tube was placed in a constant temperature oil bath at 150°C for 16 hours to react. After the reaction, the obtained polymer was dissolved in a small amount of dichloromethane, poured into a large amount of methanol for reprecipitation. The polymer was vacuum-dried at 40°C to obtain a white solid which was the amphiphilic tri-block copolymer. The yield is 59.6%, the number average molecular weight is 19000, and the polydispersity index is 1.51.

[0047] Weigh 10 mg of the above-mentioned amphiphilic tri-block cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com