Group-well fracture pressure steeping control aqueous fusion exploitation method of glauberite bal

A mining method and glauberite technology, which is applied in the mining of glauberite ore, group well fracturing, pressure soaking, and water-soluble mining, can solve the problems of high labor intensity, dangerous operating environment, and high mining cost of the mining method, and achieve The effects of high-efficiency mining, increased dissolution rate, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

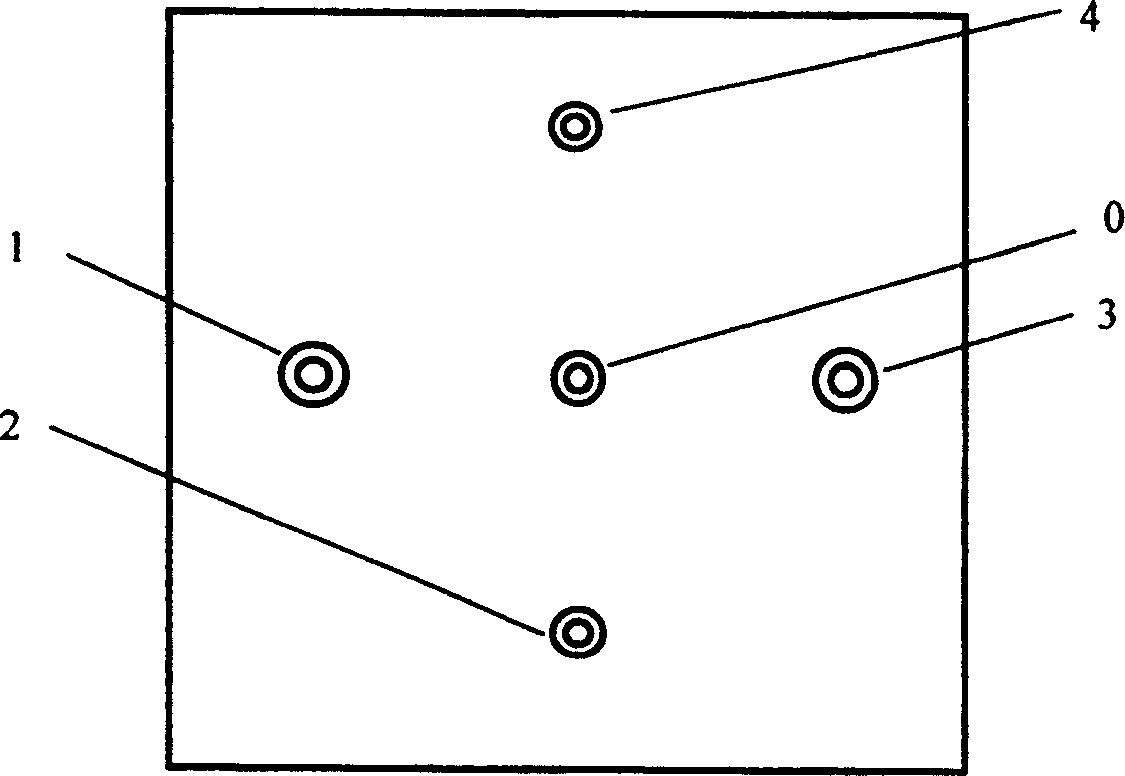

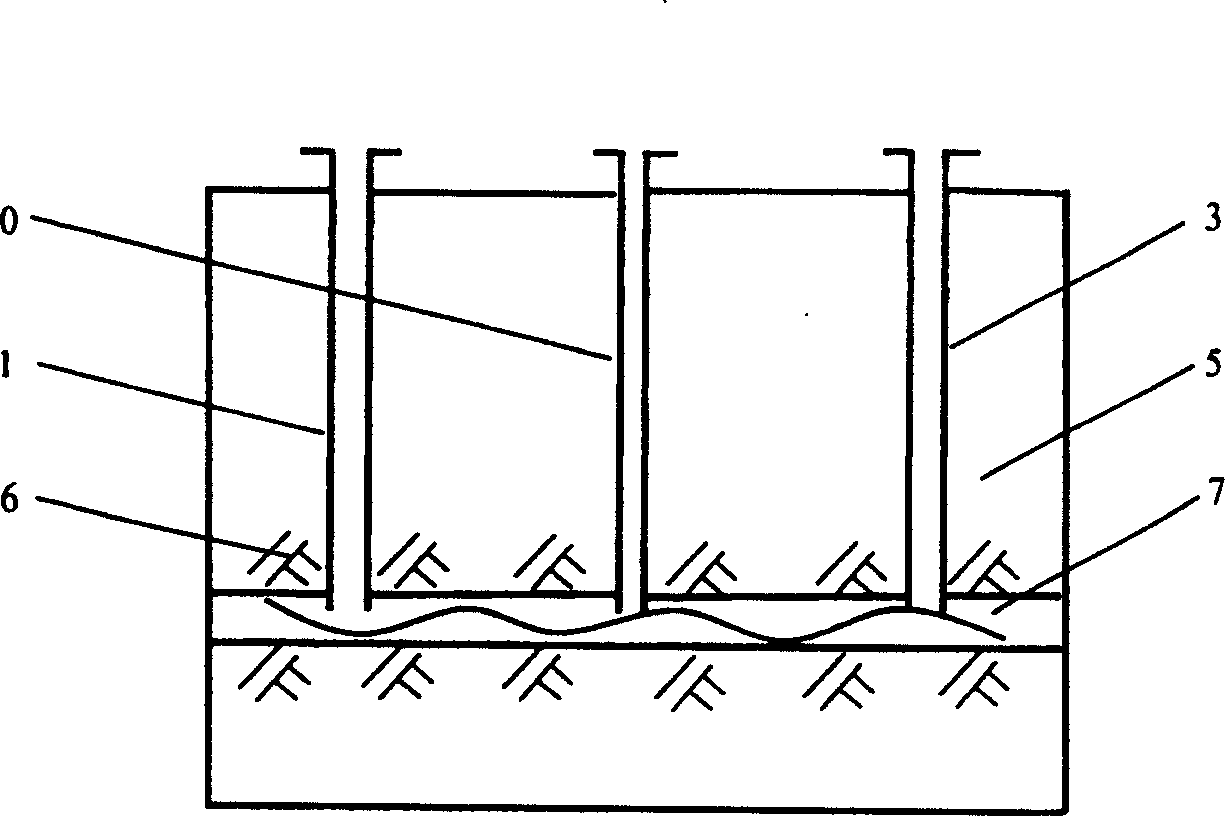

[0025] Referring to Figures 1 and 2,

[0026] A method of fracturing controlled pressure immersion water solution mining in glauberite mines, the steps of which are as follows:

[0027] (1) According to geological data, after determining the physical and mechanical properties and burial characteristics of the ore layer, according to the requirements of drilling technical specifications, select a reasonable well spacing (100m) and well location, and arrange well patterns No. 0, No. 1, No. 2, and No. 3 Wells No. 4 and No. 4 (the well pattern consists of 5 wells), implement drilling;

[0028] (2) After the open well is completed, run the casing and perform corresponding cementing according to the specifications;

[0029] (3) After all the wells are completed and cemented, the central No. 0 well is selected as the water injection well (fracturing well), and the No. 1, No. 2, No. 3, and No. 4 wells are used as the target wells, and the central No. 0 well is implemented with a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com