Quick actuated door with sector seizing-up plate

A fan-shaped clamping plate and clamping plate technology, which is applied to pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of poor stress state, short service life, and large friction coefficient of rubber materials, etc., to prolong the service life , reduce the amount of materials, the effect of clear force state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

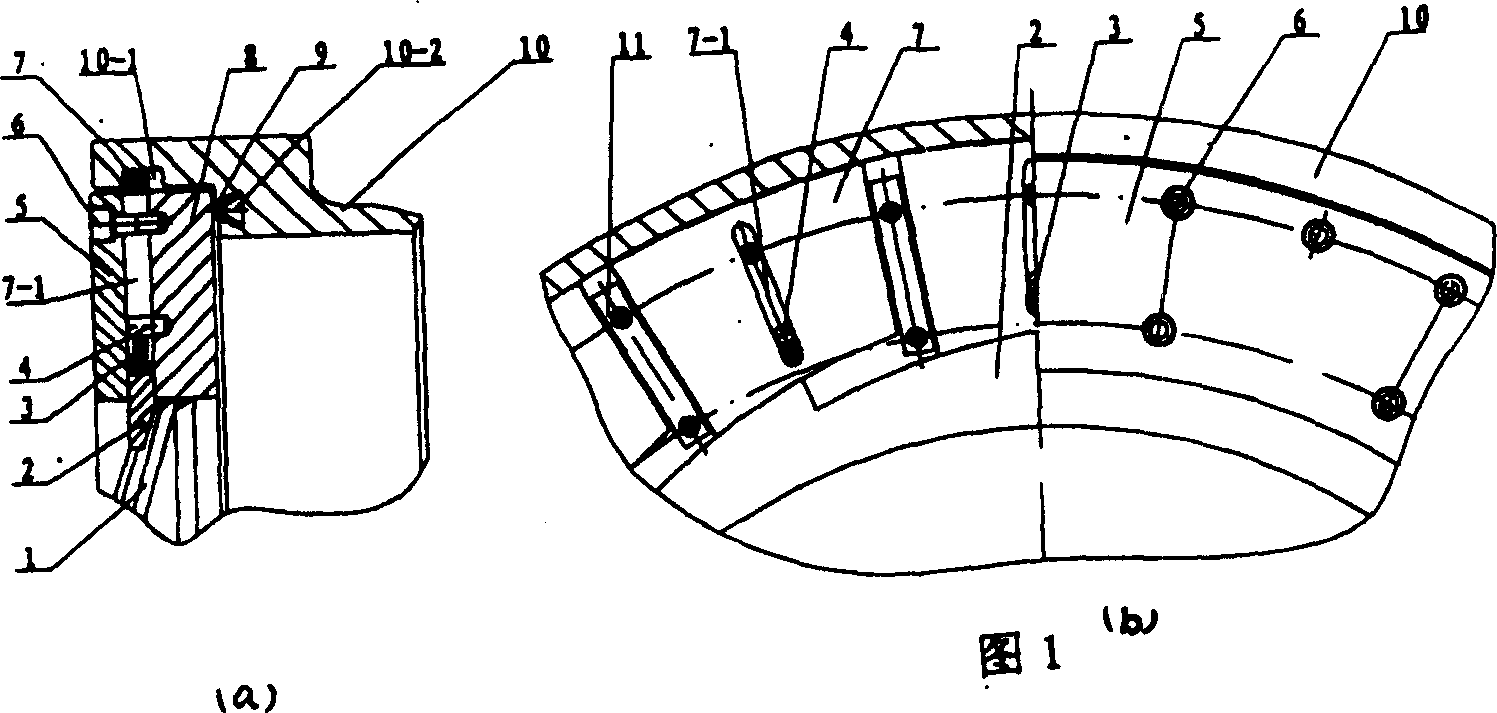

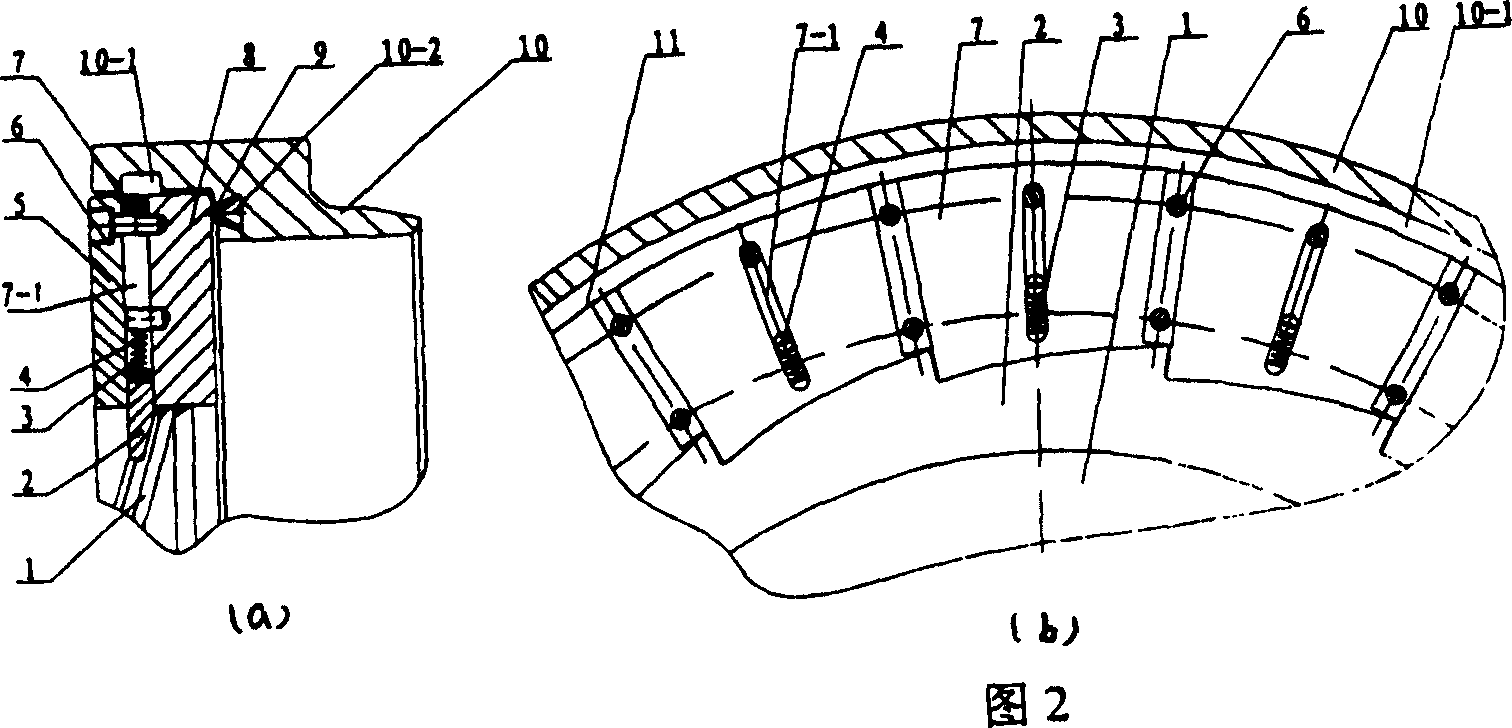

[0015] As shown in Fig. 1 (a), (b), the present invention is a kind of fan-shaped clasp type quick-opening door. It is mainly used for the so-called quick-opening door frame.

[0016] The ratchet 2 is arranged between the flange 8 and the pressure ring 5 in the axial direction, and the fan-shaped clamping plate 7 and the spacer 11 are placed radially between the flange 8 and the pressure ring 5 in the axial direction, and are placed on the outer periphery of the ratchet 2. The spacer 11 is fixed between the flange 8 and the pressure ring 5 by the fastening screw 6, and the fan-shaped clamping plate 7 is placed between two adjacent spacers 11 in the radial direction. Correspondingly, the fan-shaped clip 7 has an oblong hole 7-1 in the radial direction, and the built-in clip return device 4, 3, wherein the limit screw 4 is fixed on the flange 8, and the spring 3 is embedded in the oblong hole inside the limit screw 4 7-1 constitutes the card plate recovery device, and the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com