Steel structural beam type sliding stair and construction method

A technology for steel structure beams and stairs, applied in the direction of stairs, ladder-like structures, building structures, etc., can solve the problems that the safety and effectiveness of escape routes cannot be guaranteed, the calculation of overall force is not suitable, and the force of joint areas is complicated, etc., so as to facilitate engineering The effect of high quality, high promotional value, and reduced design workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

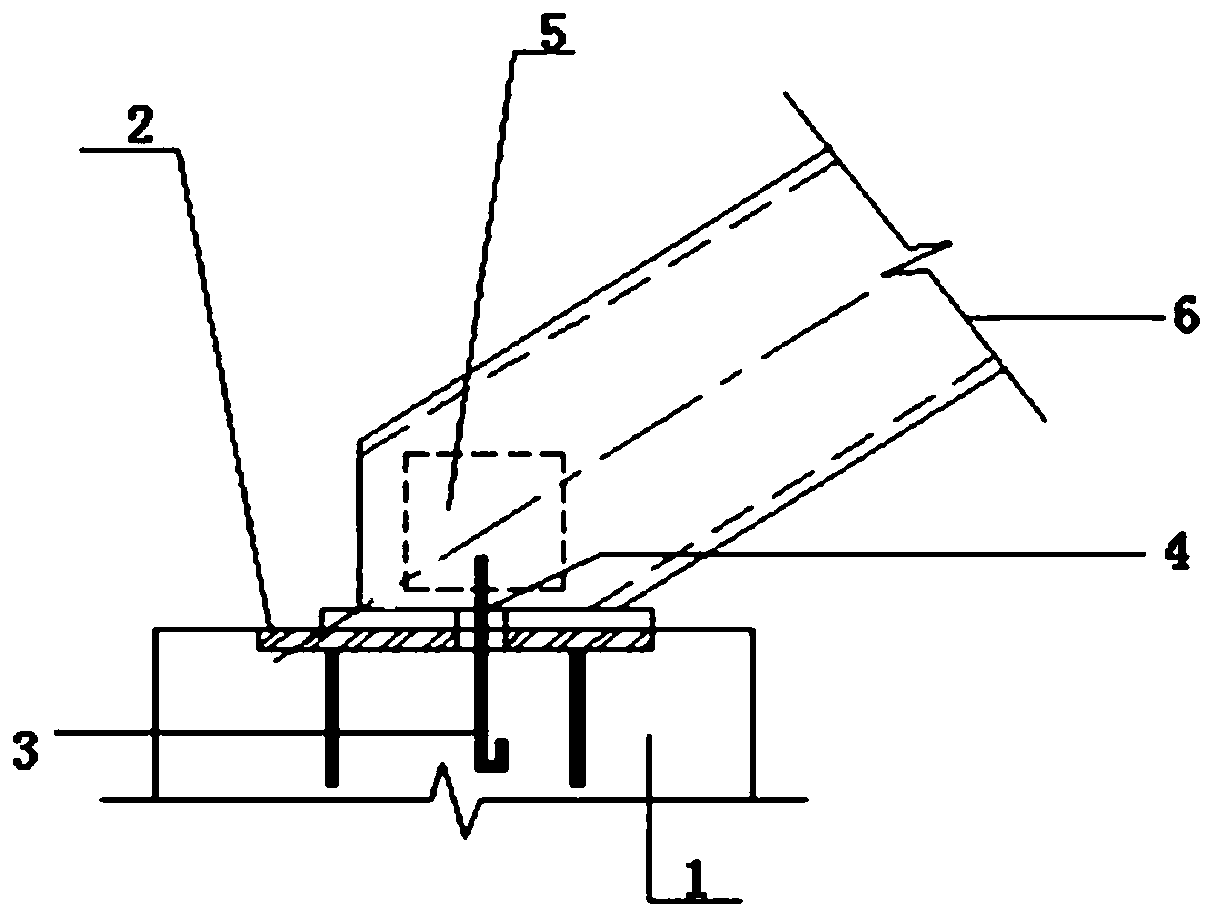

[0046] according to Figure 1-9 The shown steel structure beam type sliding staircase at least includes a staircase foundation 1, a structural bottom frame ladder beam 6 and a platform beam, and the upper part of the structural bottom frame ladder beam 6 is detachably connected to the platform beam by bolts, and is characterized in that: It also includes a limit sliding device, a non-bottom frame beam 8, a structural frame beam 7 and a connecting mechanism; the limit slide device is connected to the beam type staircase foundation 1, and the lower part of the structural bottom frame ladder beam 6 passes through the limit The sliding device is connected with the stair foundation 1; two sides of the structural frame beam 7 are respectively provided with a pick ear 9, and the middle part of the non-bottom frame beam 8 is provided with a pick ear 9; There are through holes, and the connecting mechanism connects and fixes the non-bottom frame beam 8 and the structural frame beam 7 t...

Embodiment 2

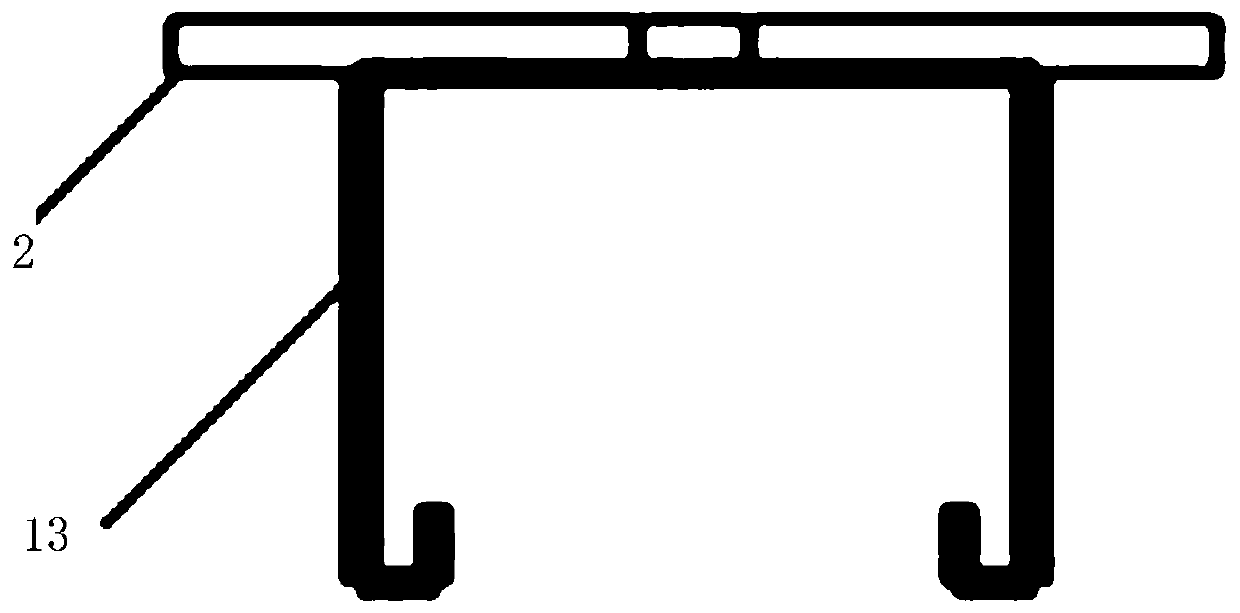

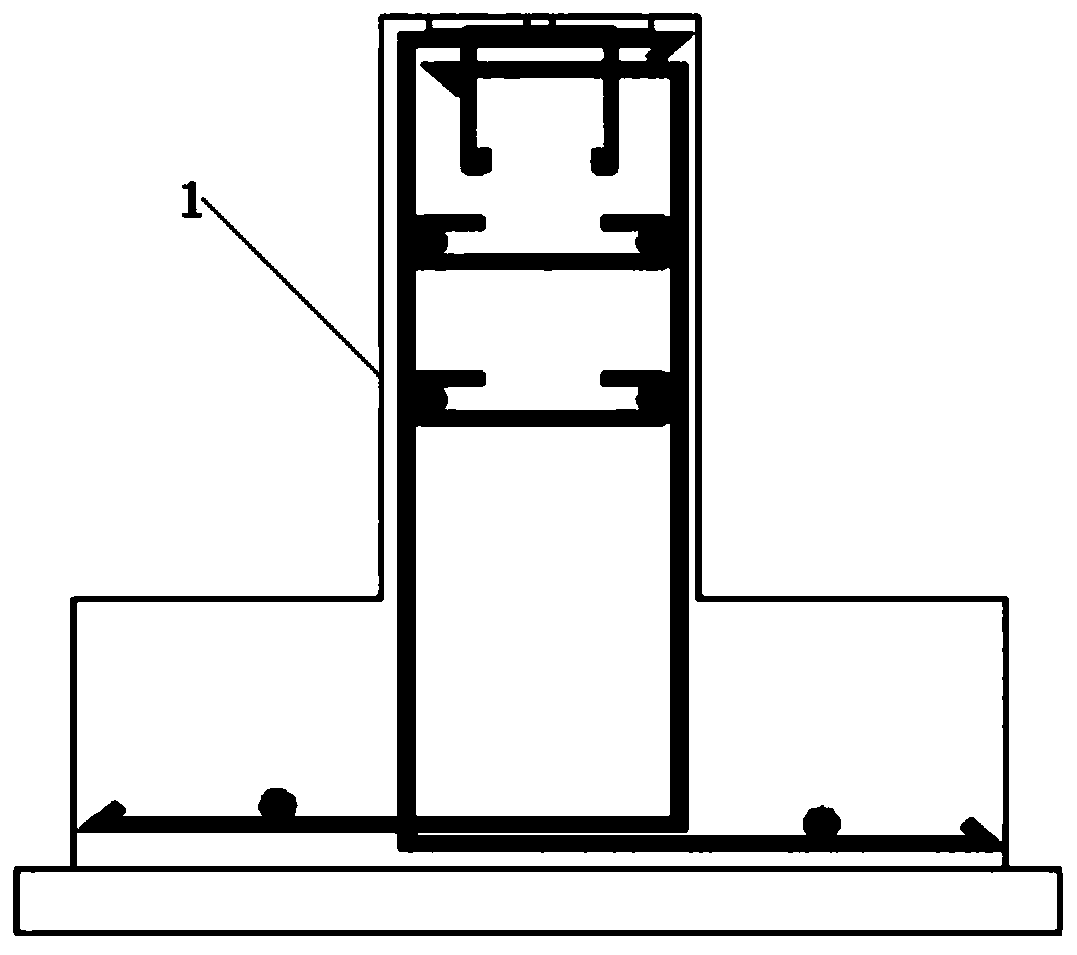

[0054] according to figure 1 , figure 2 and image 3 The steel structure beam type sliding staircase shown differs from the first embodiment in that the limiting sliding device includes embedded parts 2, embedded bolts 3, steel plates 4 and anchoring steel bars 13; the embedded parts 2 Pre-buried on the beam-type staircase foundation 1, the anchor steel bar 13 is connected to the lower surface of the embedded part 2; the steel plate 4 is connected to the upper surface of the embedded part 2; the center of the embedded part 2 and the steel plate 4 are respectively provided with reserved bolt holes; the embedded bolts 3 are connected in the reserved bolt holes.

[0055] In actual use, the steel plate 4 is welded to the ladder beam 6 of the bottom frame of the structure, and the steel plate 4 is connected with the embedded bolt 3 . The limit sliding device adopts this technical solution, which can effectively release the displacement under the action of the earthquake, so tha...

Embodiment 3

[0057] according to figure 1 , figure 2 and image 3 The steel structure beam type sliding staircase shown differs from the second embodiment in that the anchoring steel bar 13 is 2Φ8.

[0058] Further, the connection between the embedded part 2 and the anchoring steel bar 13 is welded.

[0059] Further, the embedded parts 2 are buried along the length of the steps.

[0060] In actual use, the anchoring steel bar 13 adopts 2Φ8, which can effectively anchor the embedded steel plate in the underlying foundation, and effectively transmit the frictional force generated by the displacement of the beam staircase.

[0061] The connection between the embedded part 2 and the anchoring steel bar 13 is welded; the steel plate 4 is connected with the embedded part 2 by the limited embedded bolt 3, and the bolt holes, especially the oval bolt holes, are helpful for effective Release displacement.

[0062] In actual use, the steel plate 4 and the steel plate at the bottom of the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com