Multifunctional machine for roller compacted concrete

A technology of roller compacted concrete and multifunctional machine, which is applied in building components, building insulation materials, construction, etc., can solve the problems of high labor intensity, slow construction speed, low degree of mechanization, etc., and achieves the goal of improving construction quality and accelerating construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

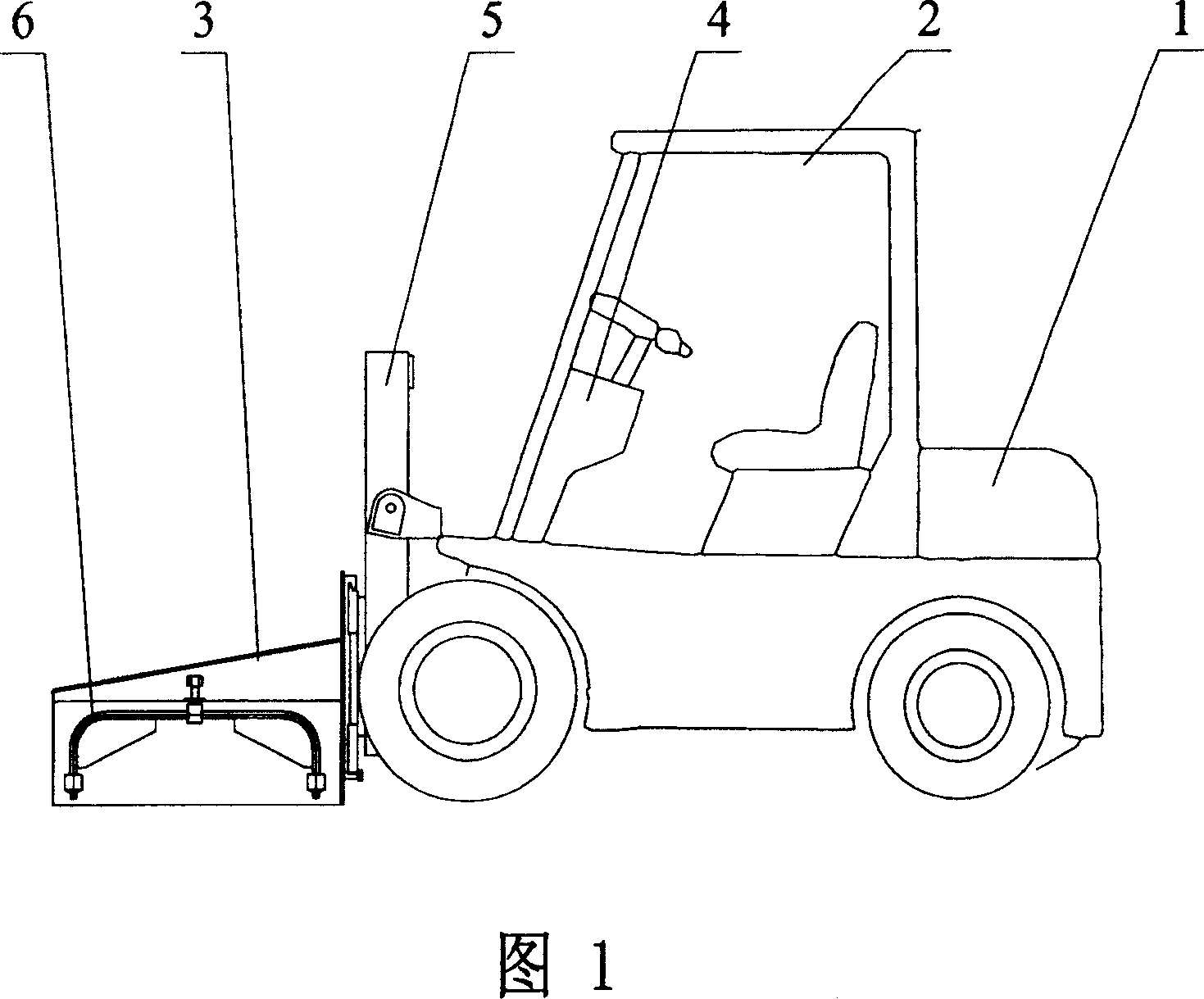

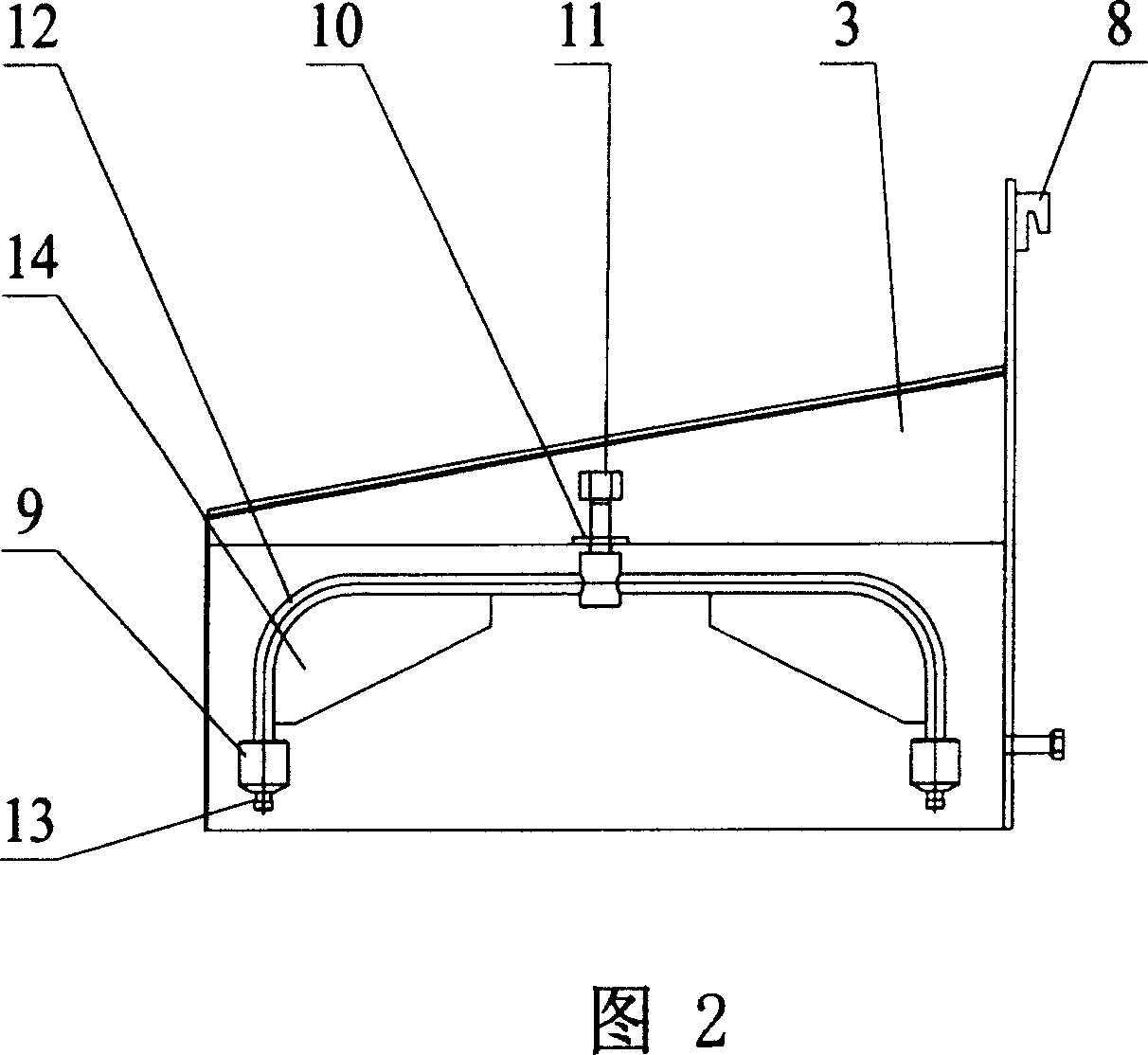

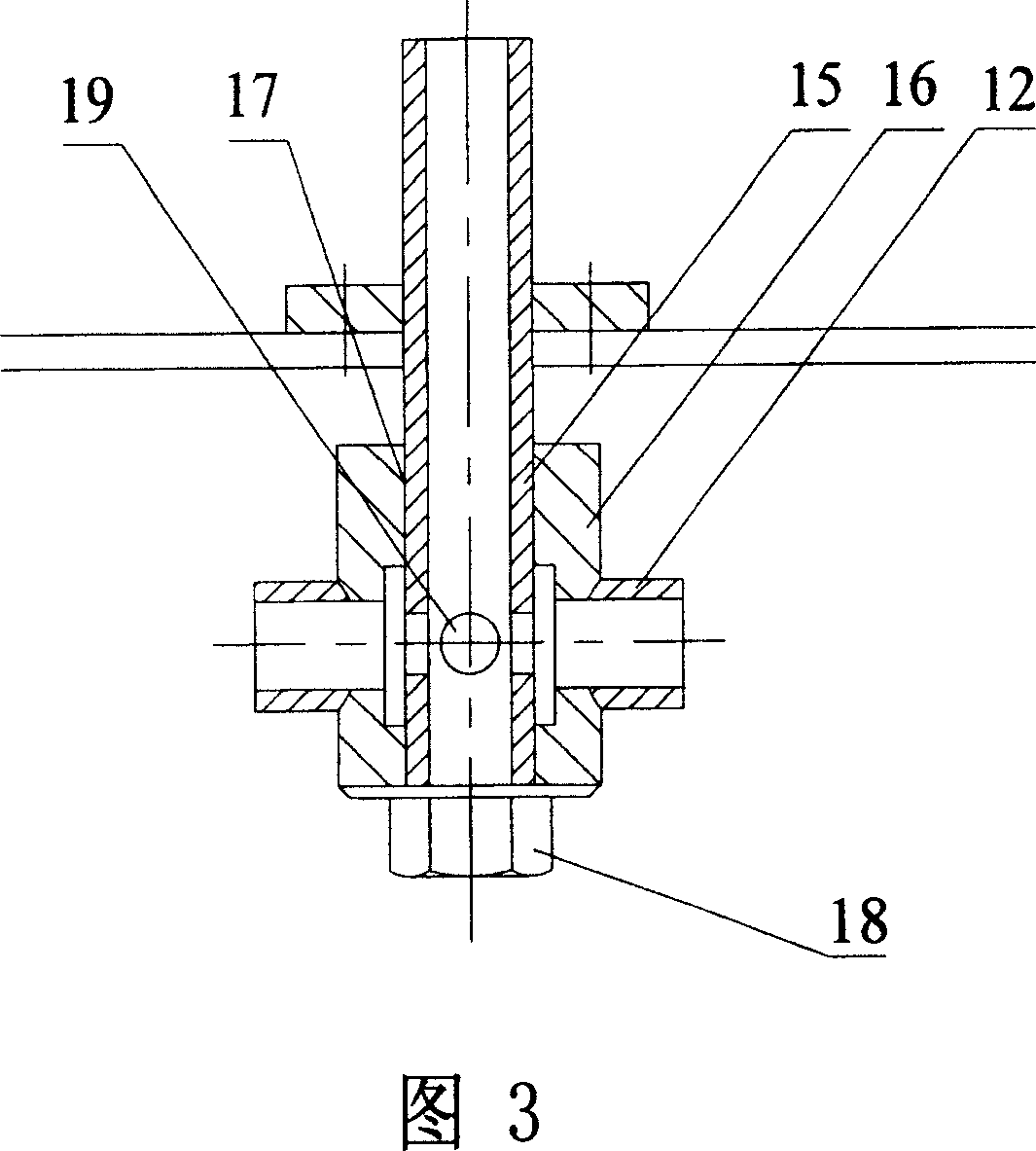

[0024] A kind of roller compacted concrete multifunctional machine of the present invention combines the active module and the roughening working module to constitute the concrete high-pressure water roughening vehicle, as shown in Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5, it consists of The active module (including body 1, cab 2, frame 3, connecting work frame 5) is composed of a punching work module, and the punching work module is movably connected with the active module connection work frame 5 through the frame 3, and the active module is set There is a controller 4, which is connected with the motion control device in the flushing module 6 by cables. The connecting working frame 5 is located at the front end of the vehicle body 1, and is fixedly connected with the vehicle body 1. The connecting working frame 5 is provided with a "V"-shaped groove 7, which matches the hook 8 on the frame 3 and is movable. connect. The controller 4 is a programmable controller. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com