Assembling composite shore

A pillar and column head technology, which is applied in the field of cushioned composite pillars, can solve the problems of wood consumption and achieve the effects of simple manufacture, labor-saving erection, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

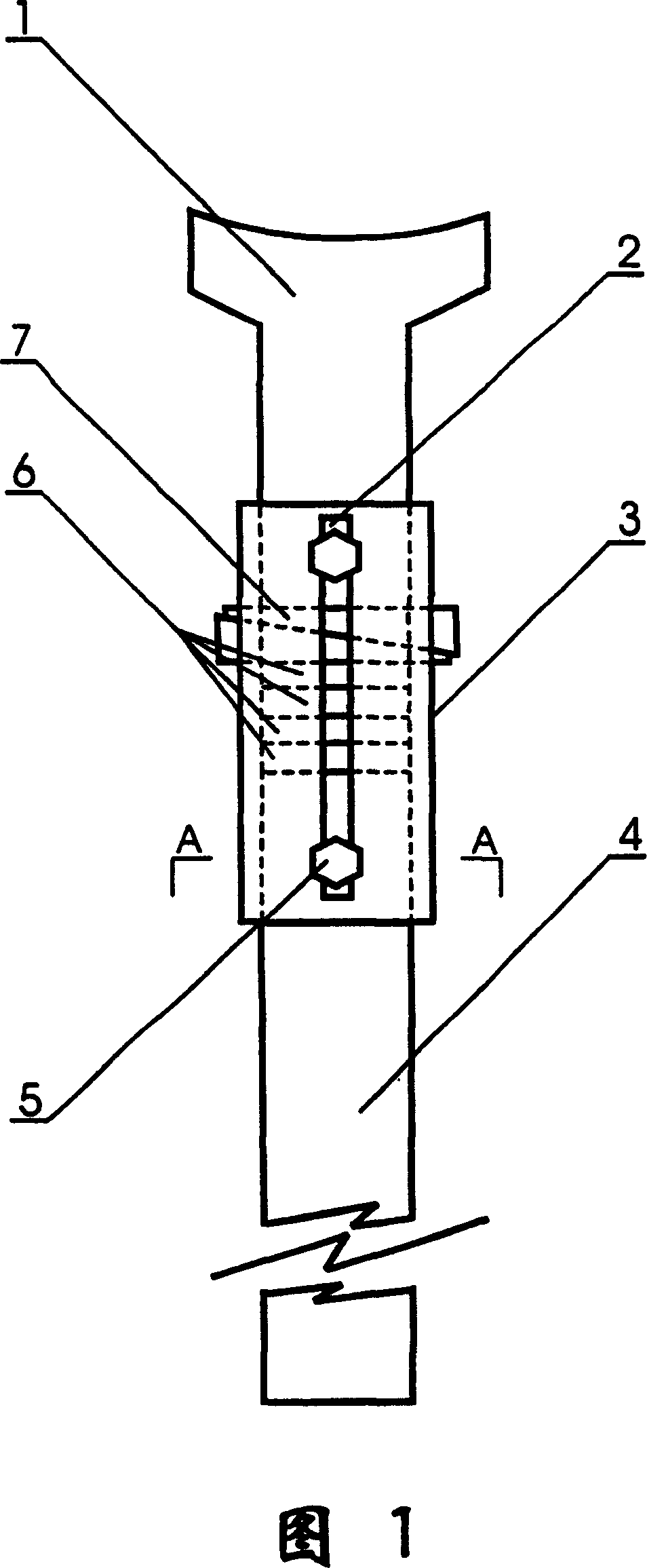

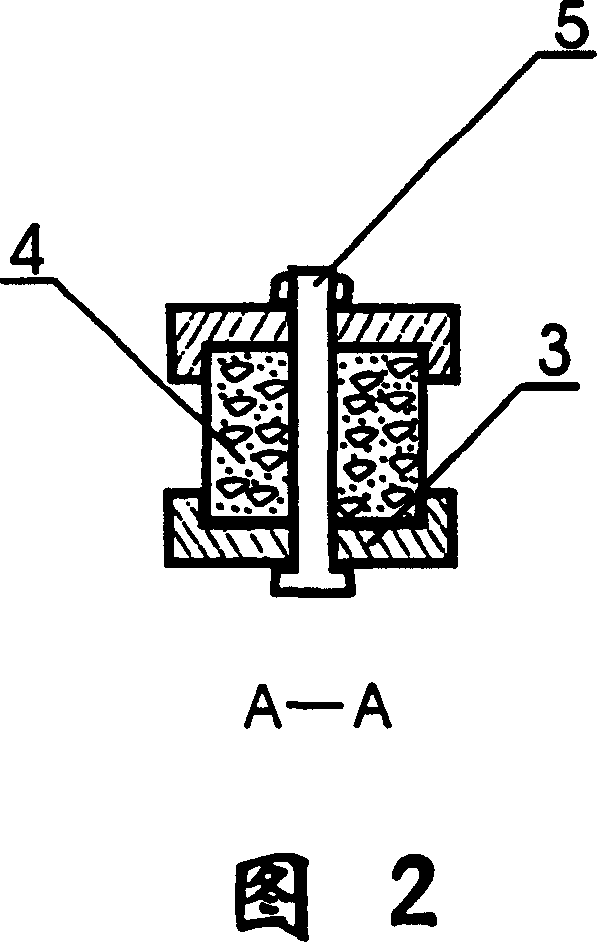

[0008] In the following, the pad-mounted composite pillar of the present invention will be described in further detail in conjunction with the examples of the above-mentioned drawings. An example of the present invention includes a column head 1 , a jacket 3 , a column shaft 4 , a bolt 5 , a shrinkable object 6 , and a wooden wedge 7 . The vertical centerline of the jacket 3 is provided with a strip groove 2, and the lower part of the column head 1 and the center of the upper part of the column body 4 are respectively provided with screw holes. The jacket 3 fastens the column head 1 and the column body 4 into one body by two bolts 5 passing through the strip groove 2 and the screw holes on the column head 1 and the column body 4 respectively. The top of column head 1 can be designed as arc or flat according to different support requirements. Column head 1 and column body 4 are made of concrete pouring or metal profile, and its section is rectangular or circular or other shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com