Combine harvester

A combine harvester and body technology, which is applied in the directions of harvesters, cutters, agricultural machinery and implements, can solve the problems of complex structure and inability to stably support grain storage devices, etc., so as to improve work efficiency and improve sorting performance. , the effect of shortening working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the present invention will be described with reference to the drawings.

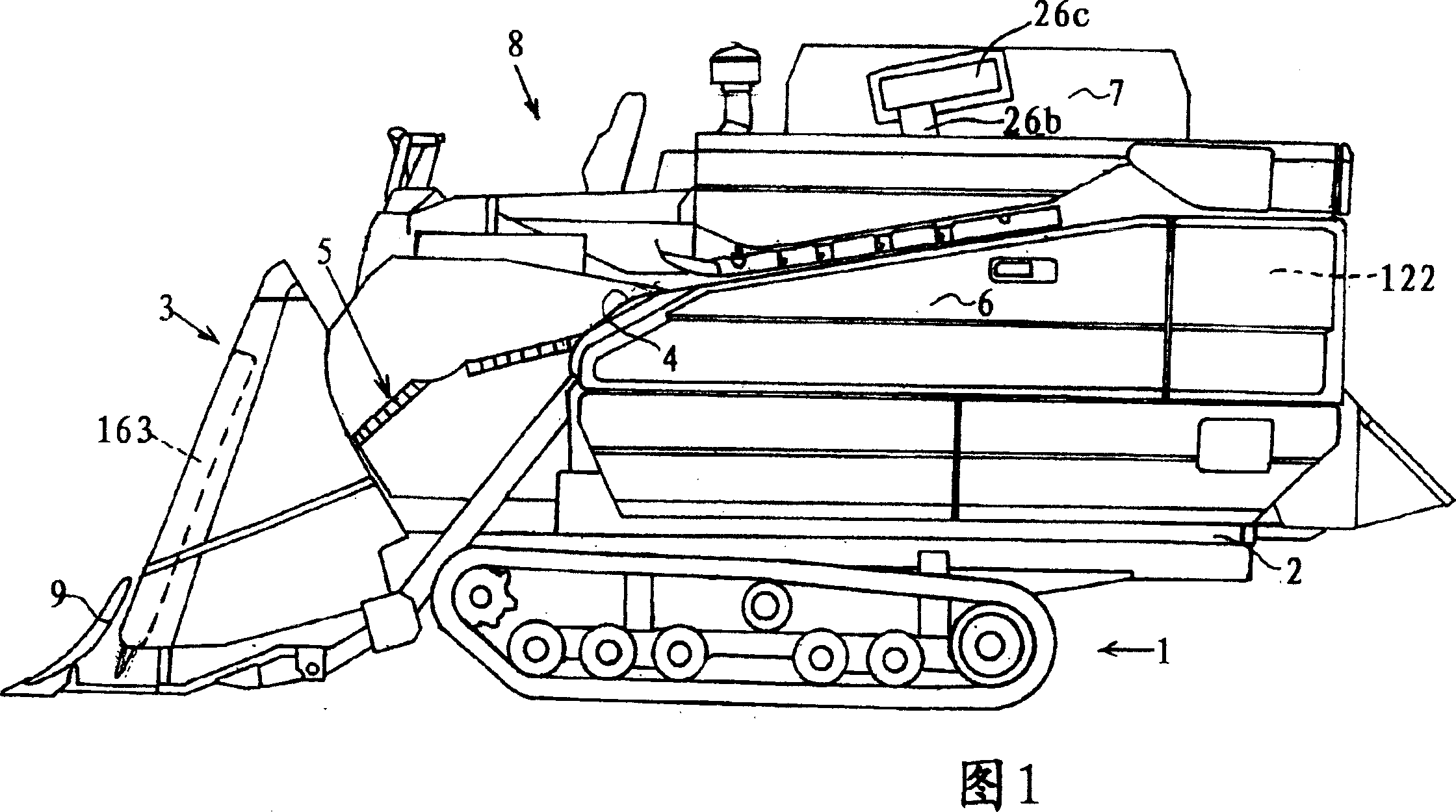

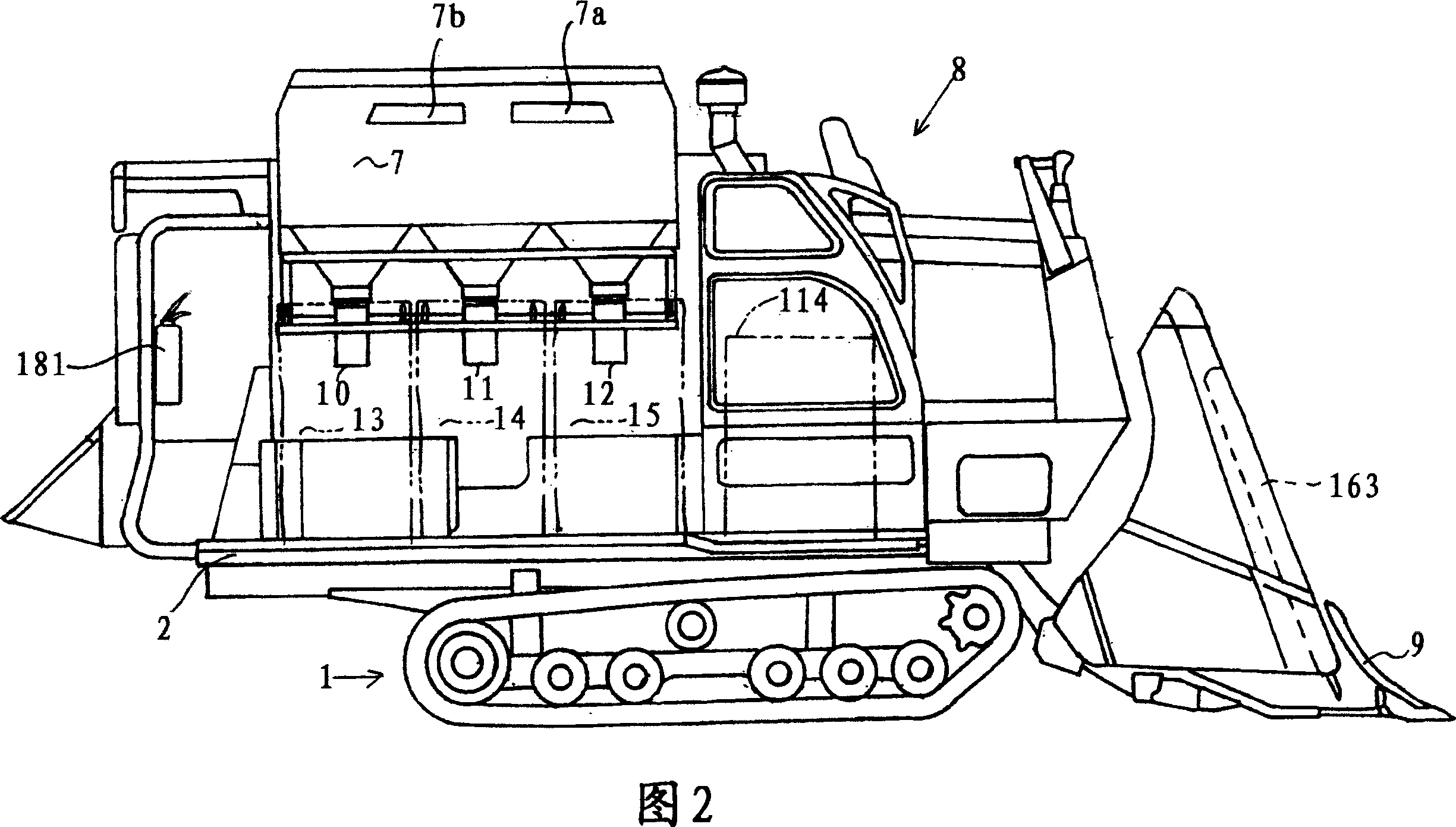

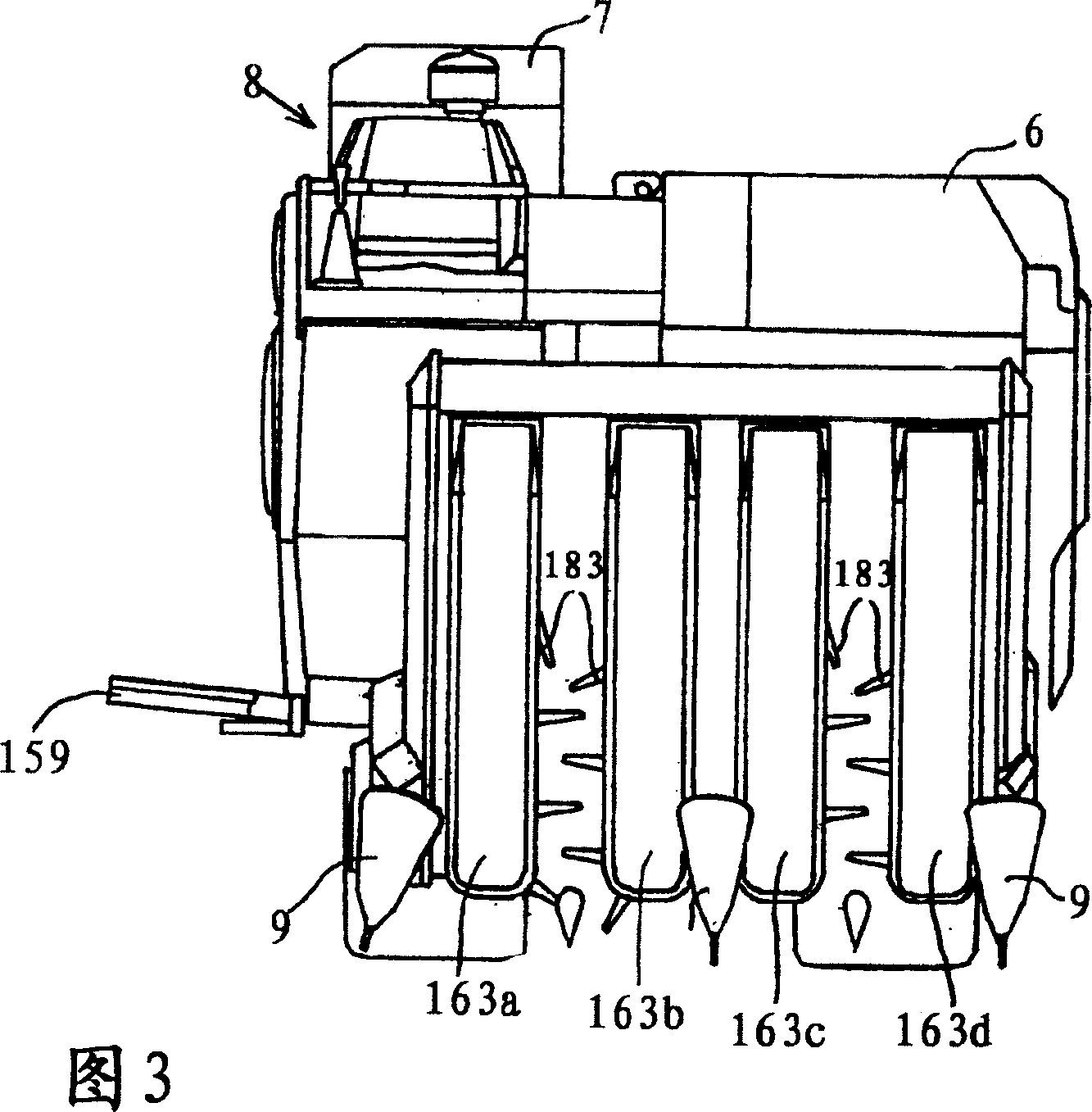

[0067] FIGS. 1-3 have shown the combine which is an agricultural machine which actualized embodiment of this invention. Fig. 1 is a right side view of the combine harvester, Fig. 2 is a left side view of the combine harvester, and Fig. 3 is a front view of the combine harvester.

[0068] In front of the chassis 2 with the walking device 1, a harvesting device 3 and a supply conveying device 5 are provided. 3. The grain stalk that conveys comes and conveys toward the feeding chain 4 of rear again. The threshing apparatus 6, the grain storage apparatus 7 (henceforth a grain tank) and the operation part 8 are mounted on the said chassis 2. As shown in FIG. The threshing device 6 performs threshing and sorting while receiving and conveying the grain stems conveyed from the supply conveyor 5 by the feed chain 4 , and the grain storage device 7 temporarily stores the grains threshed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com