Feeding and supporting unit of movable drilling machine

A technology of supporting device and drilling machine, which is applied to supporting devices, portable drilling rigs, rotary drilling rigs, etc., can solve the problem that manual control of the supporting device cannot be realized, and achieve the effect of comfortable control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

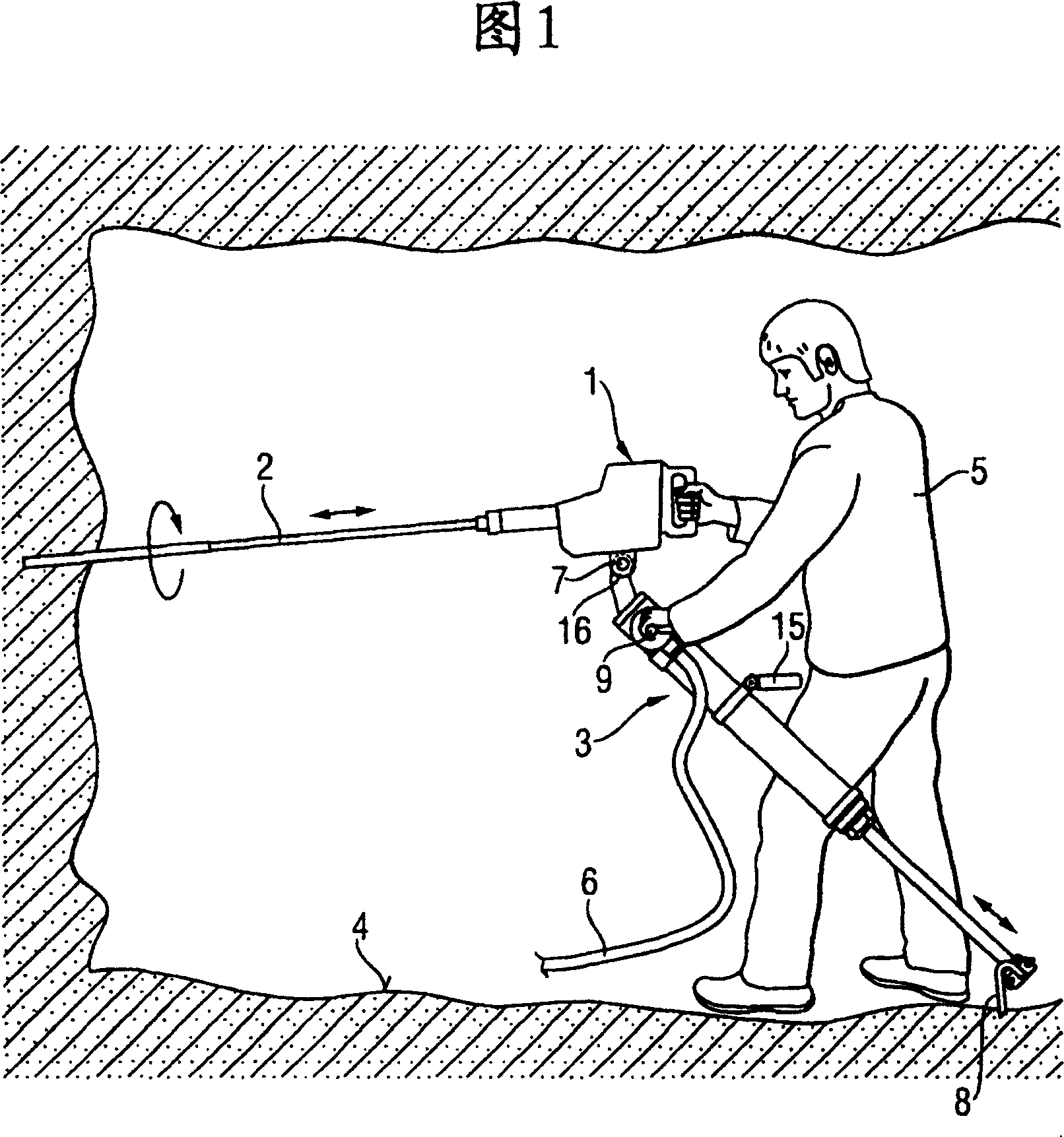

[0020] According to FIG. 1 , in underground mining, on a mobile drilling machine 1 with a rotating and impact-driven, water-washed long drill bit 2 , an easily assembled working cylinder 3 is provided on one side of the device. The feed support device is formed as a support device resting on the ground 4 and at the same time exerts a controllable feed force acting in the direction of the tool on the drill head 2 . The working cylinder 3 whose rear end is inclined downward is operated and controlled by the hands of the user 5 . Water is supplied to the working cylinder 3 via a pressure hose 6 and to the drill bit 2 via the drilling machine 1 .

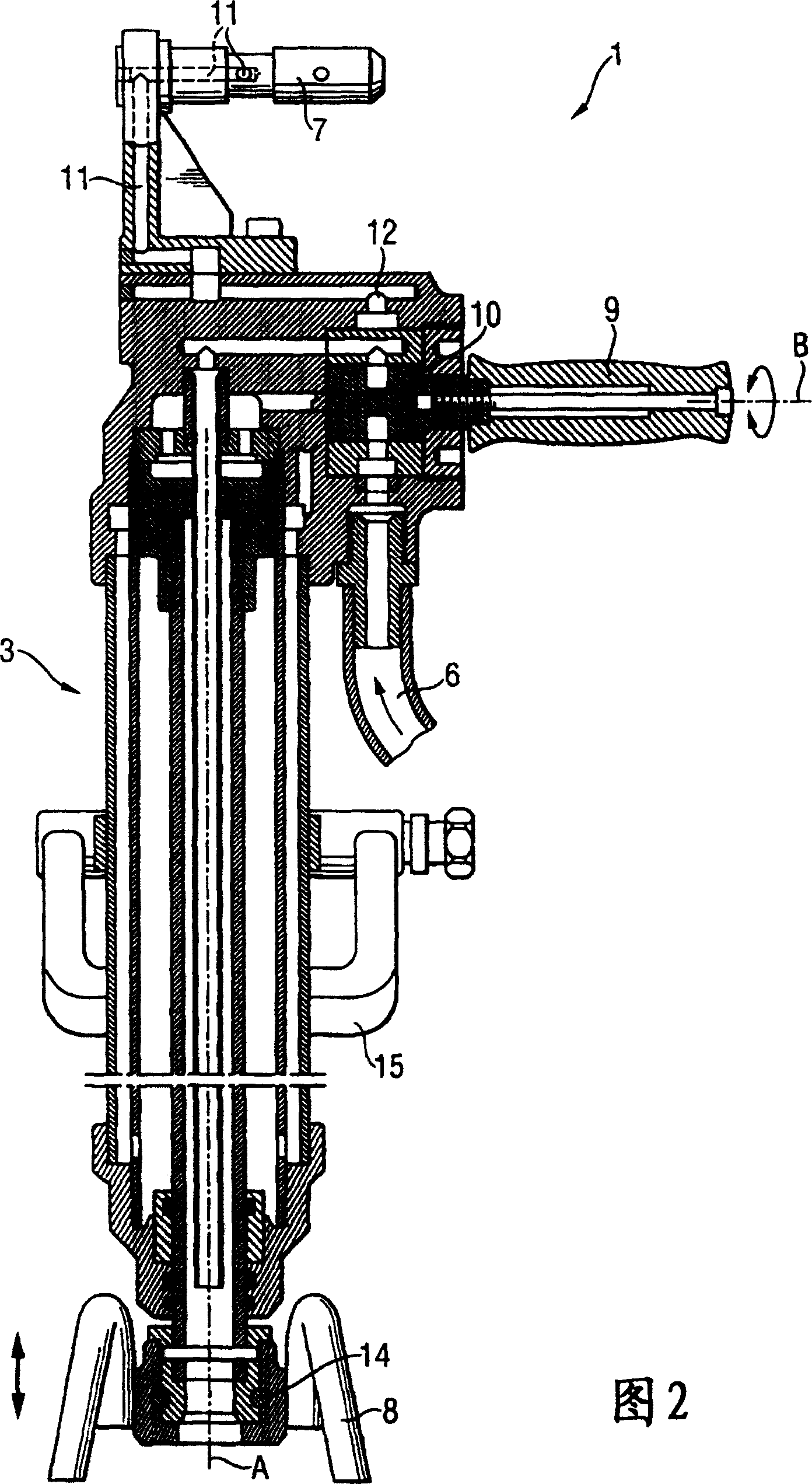

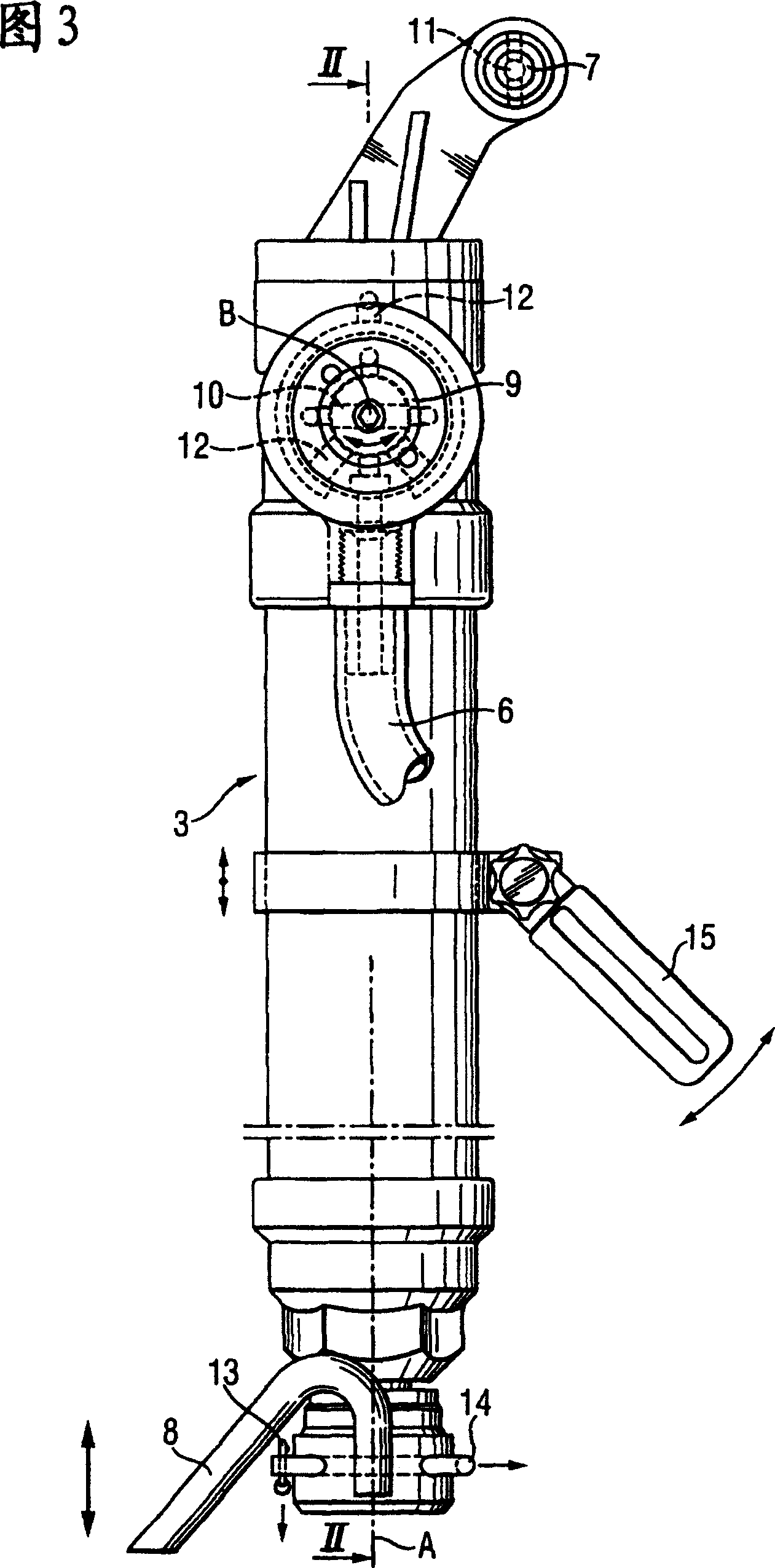

[0021] According to FIGS. 2 and 3 , the feed support device consists of a hydraulically driven working cylinder 3 acting on both sides, which has at a first end a mounting device 7 which can be easily mounted on the drilling machine and at the A second end has a foot 8 . The working cylinder 3 is continuously controlled via a manually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com