Comber for rotary clamp bed

A combing machine and combing technology, applied in the direction of combing machines, textiles, papermaking, fiber processing, etc., can solve the problems of airflow interference, loud noise, machine body vibration, etc., and achieve improved carding degree, good machine sealing, dynamic The effect of distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

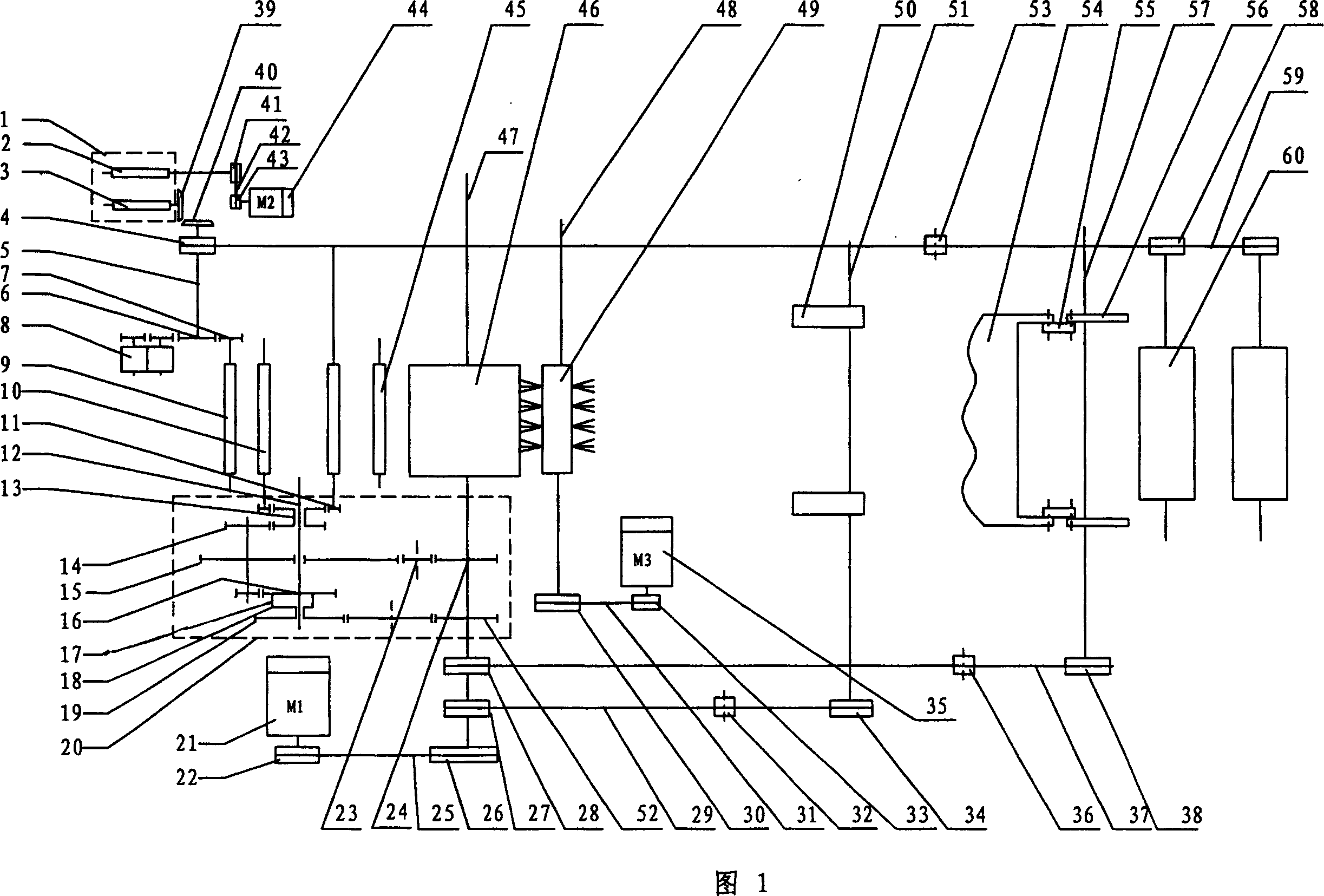

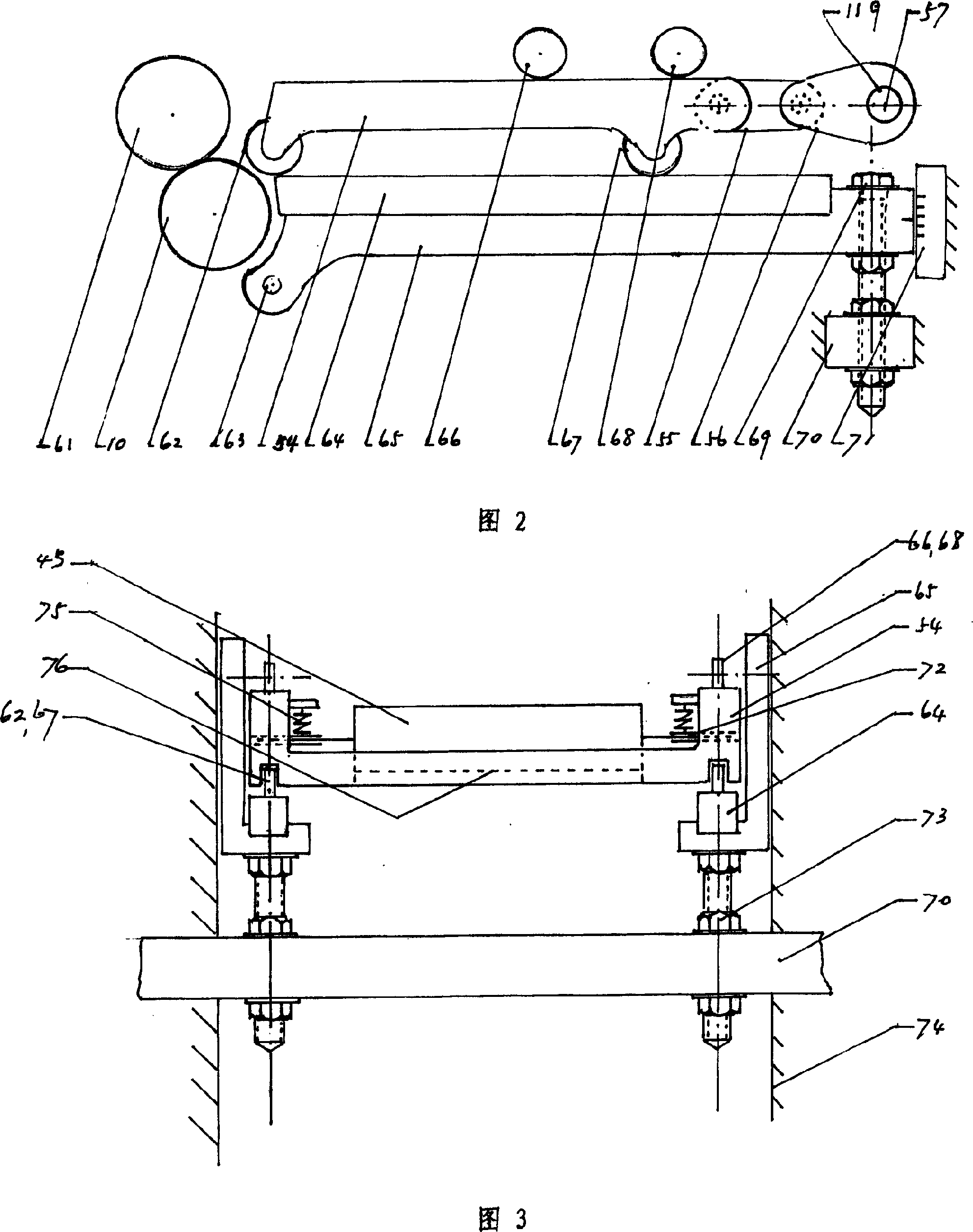

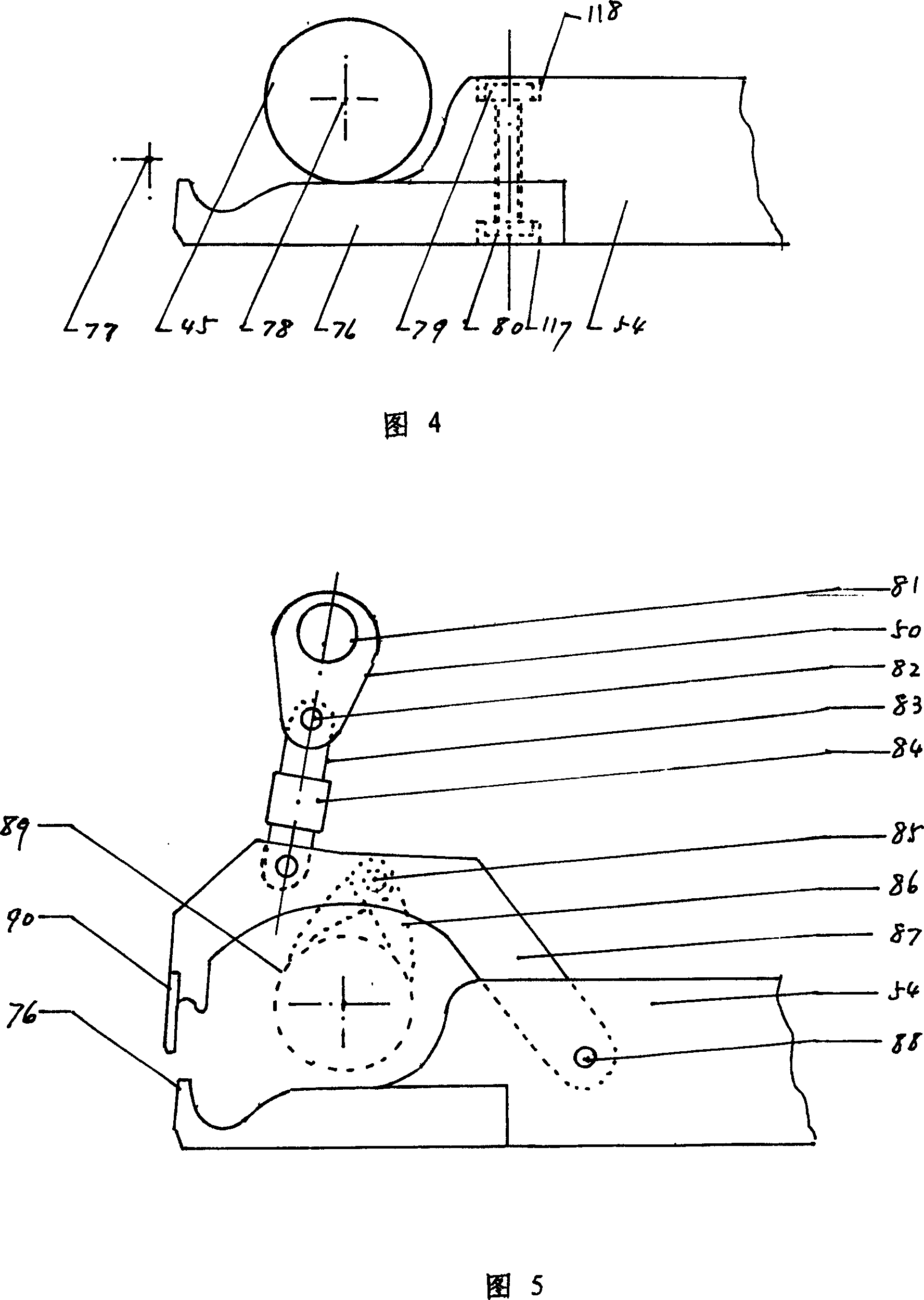

[0045] As shown in Figure 1-8. The present invention provides a combing machine with a rolling pincer bed, which is composed of eight combing heads. The structure of one combing head is shown in the accompanying drawings as an example to illustrate its structural relationship.

[0046] Please refer to Fig. 1, the main motor 21 (M1) transmits the power to the cylinder shaft 47 through the sheaves 22, 26 and the triangular belt 25, and the cylinder shaft transmits the power through the sprocket 28, 38 tension wheel 36 and the toothed belt 37 Assigned to the eccentric shaft 57, the eccentric sleeve 56 of the eccentric disk 119 sleeved on the 57 drives the clamp bed 54 to reciprocate through the hinged connecting rod 55.

[0047] The cylinder shaft 47 distributes the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com