Electrolytic water and its generating device

A generation device and electrolyzed water technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve problems such as high price, harmful gas treatment, and regular replacement, and achieve structural Inexpensive, long-term stable use, simple structure and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

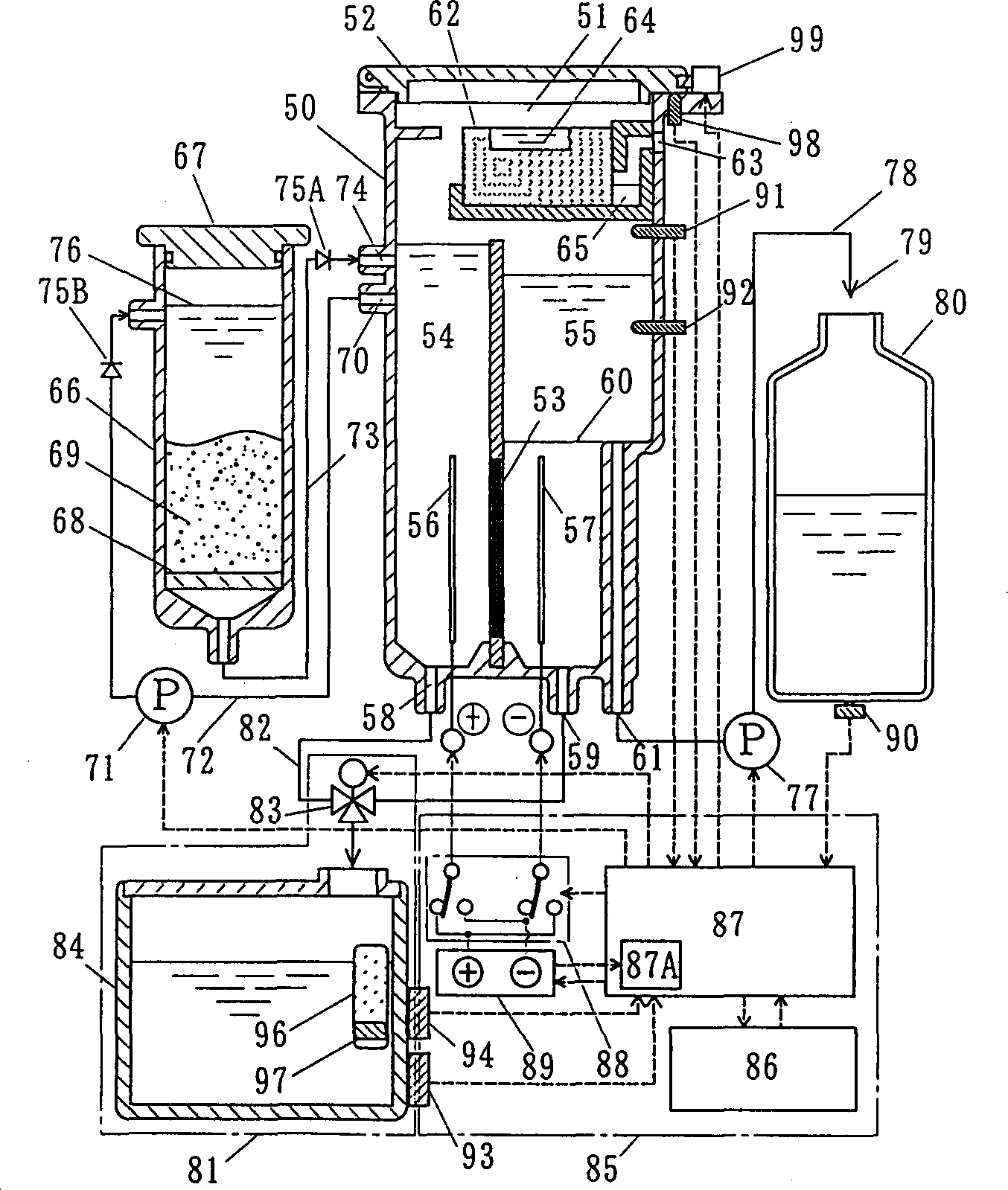

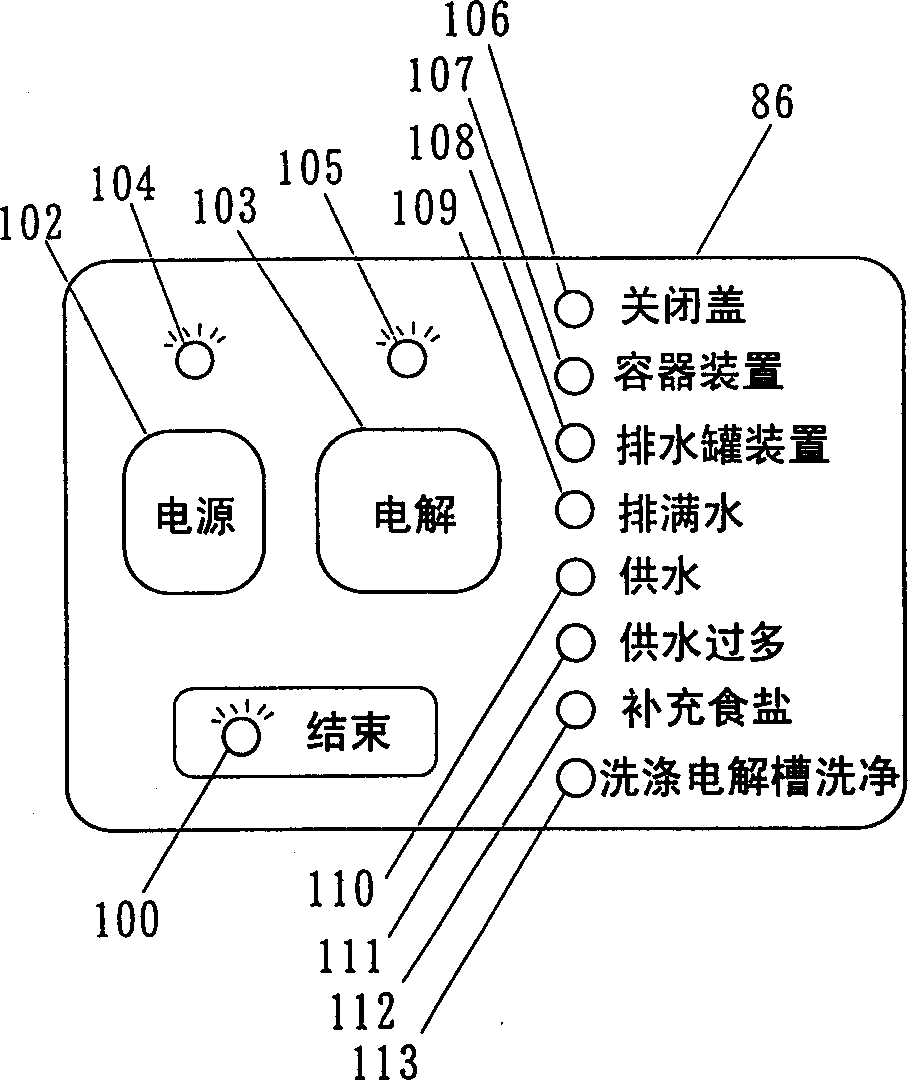

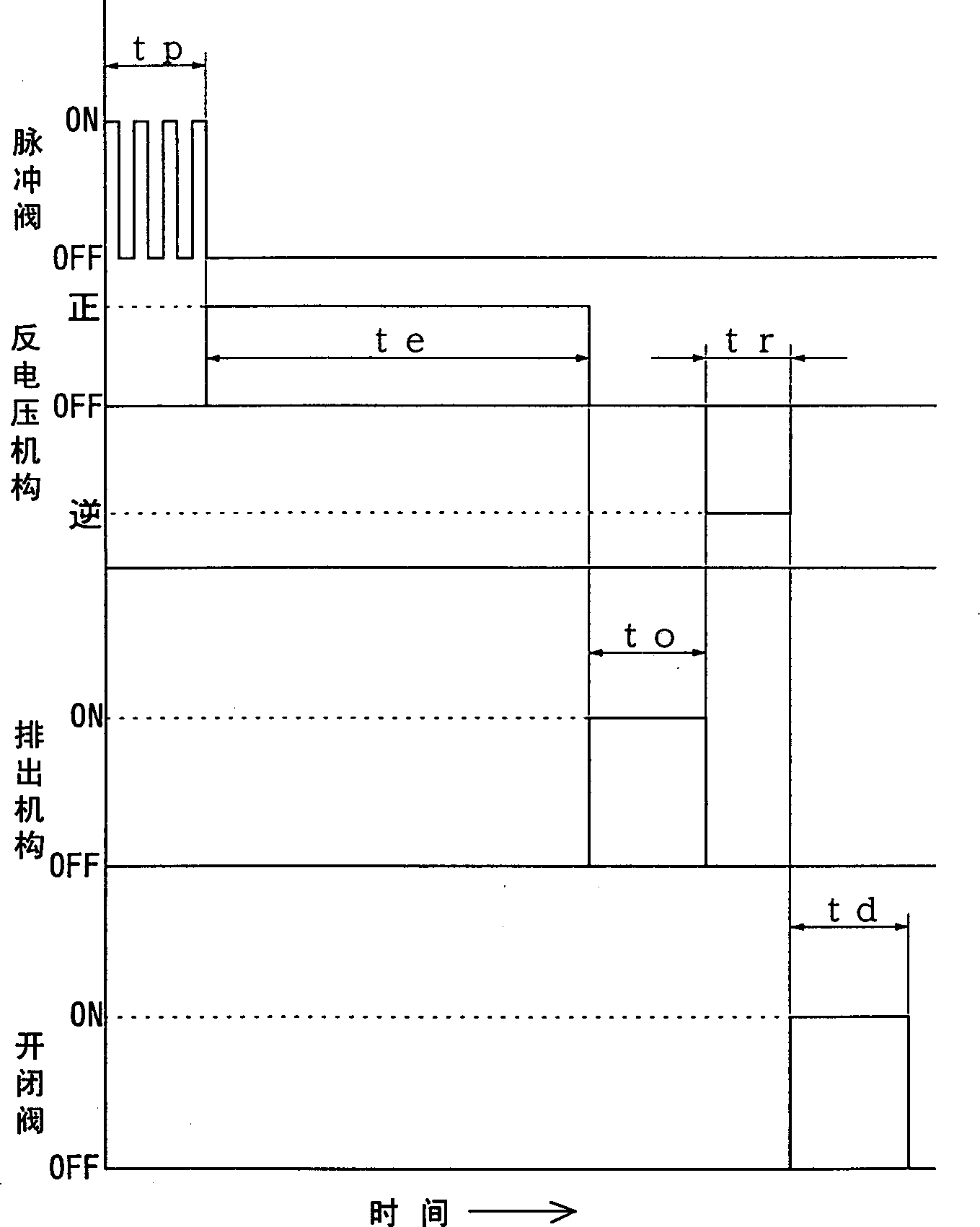

[0120] figure 1 A configuration diagram showing an electrolyzed water generator according to Example 1 of the present invention. figure 2 It shows the operation panel of the control mechanism of Embodiment 1 of this invention. image 3 A time chart showing the control operation of Embodiment 1 of the present invention. Figure 4 An external view showing the electrolyzed water generating device of Example 1 of the present invention. Figure 5 A state characteristic diagram showing hydrogen ion concentration (pH) and available chlorine.

[0121] This example shows the case where alkaline water is used as electrolyzed water and used as washing water. figure 1 Describe the center. exist figure 1 Among them, 50 is an electrolytic cell that closes the water supply port 51 at the upper end with an electrolytic cell cover 52 to make it into a sealed state, and an anode chamber 54 and a cathode chamber 55 are formed by an ion-permeable diaphragm 53, and each anode 56 and catho...

Embodiment 2

[0198] Figure 11 A configuration diagram showing an electrolyzed water generator according to Example 2 of the present invention. In addition, the same code|symbol is used for the same structure as the electrolyzed water generator of Example 1, and description is abbreviate|omitted.

[0199] exist Figure 11 In the process, the electrolyte retaining part 130 for retaining the salt water at the bottom of the anode chamber 54 of the electrolytic cell 50 and the interface 131 between the high-concentration salt water and the raw material are formed.

[0200] The electrolyte is saturated brine supplied from the electrolyte tank 66. When a predetermined amount of saturated brine is supplied to the raw water in the anode chamber 54, the brine sinks to the bottom of the anode chamber 54 due to its specific gravity difference. Then, it stays in the electrolyte storage part 130 . At this time, the saturated salt water is slightly diluted, but still maintains a high concentration of...

Embodiment 3

[0205] Figure 12 A configuration diagram showing an electrolytic cell of an electrolyzed water generator according to Example 3 of the present invention. In addition, the same structure as the electrolyzed water generator of Example 1 and Example 2 is assigned the same code|symbol, and the description is abbreviate|omitted.

[0206] exist Figure 12 In the anode chamber 54 of the electrolytic cell 50, an inclined surface A136 and an inclined surface B137 are provided at the bottom of the anode chamber 54, and an electrolyte retention part 138 for retaining electrolyte saline is formed. The electrolyte is saturated saline supplied from the electrolyte tank 66 , which settles to the bottom of the anode chamber 54 due to the difference in specific gravity, is introduced from the inclined surface A136 and the inclined surface B137 , and accumulates in the electrolyte retention part 138 . At this time, although the saturated salt water becomes slightly thinner, it still maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com