Production of semi-solid aluminium alloy size

A semi-solid, aluminum alloy technology, applied in the direction of chemical instruments and methods, mixers, dissolution, etc., can solve the problems of preparation efficiency and preparation cost limitations, inability to apply large-scale production, limited grain refiners, etc., to achieve shortening Pulping time, improvement of preparation efficiency, effect of inhibiting dendrite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A356

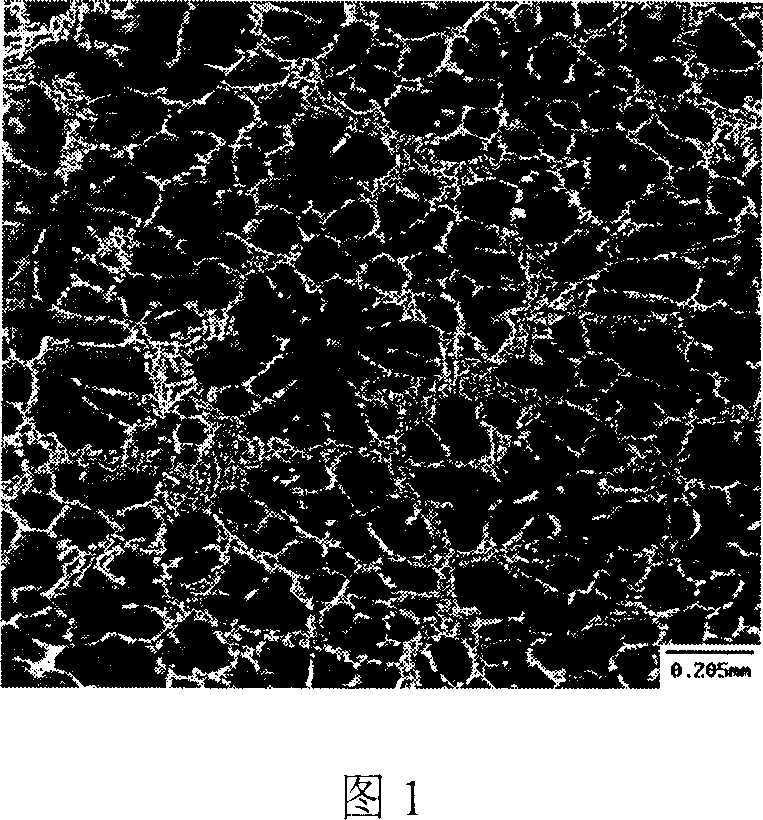

[0036] The preparation of embodiment A356 alloy semi-solid slurry

[0037] First, the A356 alloy ingot is melted in a resistance furnace. The temperature of the A356 alloy melt is 640°C±5°C, and the holding time is 30 minutes to ensure that the temperature of the melt is uniform; while the melt is keeping warm, the stirring crucible is preheated to 400 ℃. Then turn on the electromagnetic stirrer, and after about 10 seconds, pour the A356 alloy melt that has been kept at low temperature into the stirring crucible, put the crucible into the inner cavity of the electromagnetic stirrer, and start electromagnetic stirring. Electromagnetic stirring process parameters are as follows: forward-reverse non-intermittent two-way stirring, pouring temperature T 0 =640°C, stirring frequency f=30Hz, output voltage U=220V, one-way stirring time Δτ=5s. The temperature of the slurry is collected in real time during the stirring process, and the stirring is stopped when the temperature drops t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com