Sealing structure of cabin for building machinery

A technology of construction machinery and sealing structure, which is applied in the direction of construction, mechanical equipment, connecting components, etc., can solve the problems of unsealable, noise or dust intrusion, and cannot be reliably prevented, and achieve the effect of improving assembly and preventing intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, specific details of the sealing structure of the construction machinery cab of the present invention will be described with reference to the accompanying drawings.

[0018] The embodiment will be described.

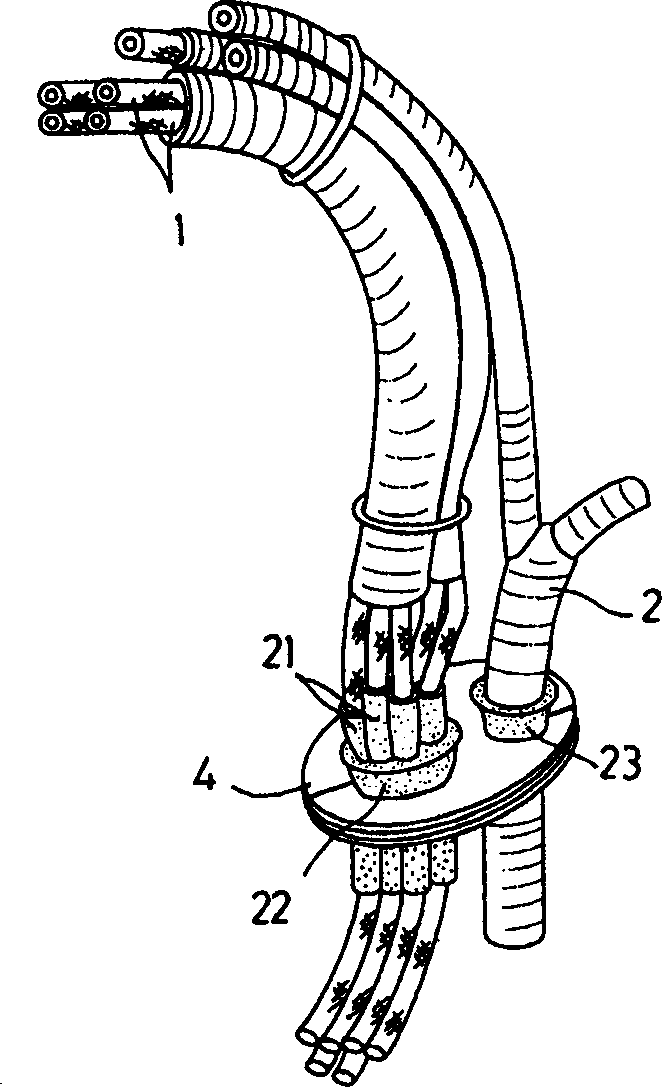

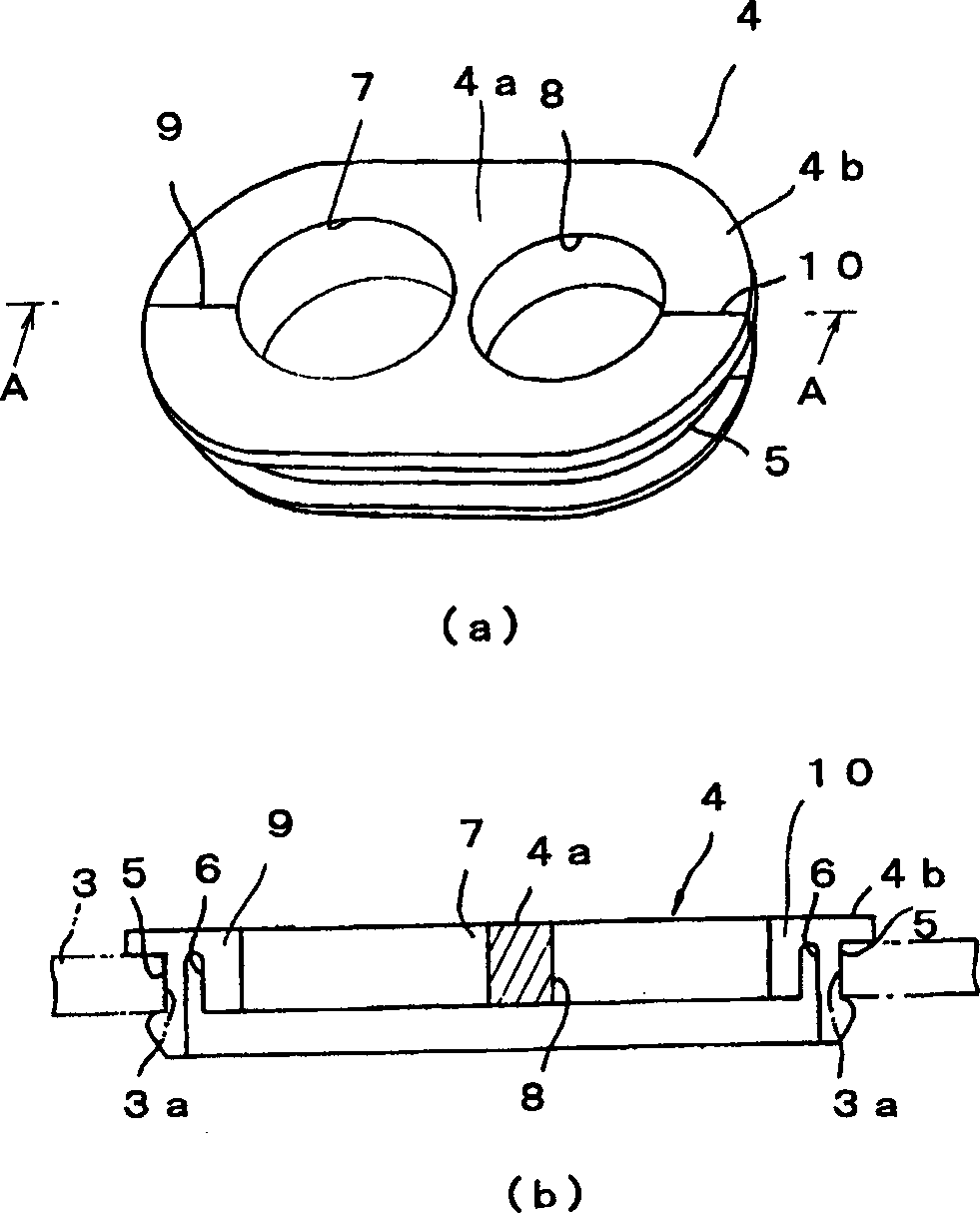

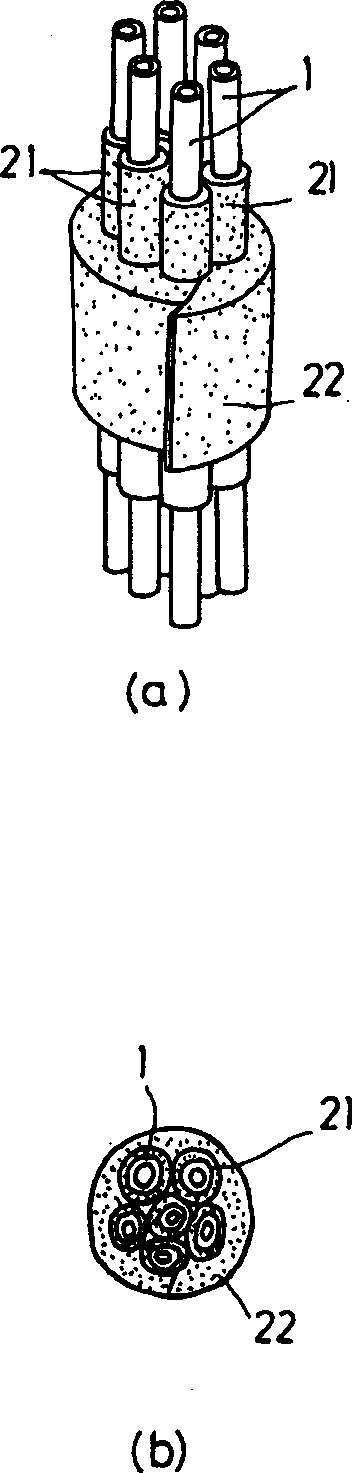

[0019] figure 1 A perspective view showing a cab sealing structure according to an embodiment of the present invention applicable to a hydraulic excavator, figure 2 It is the perspective view (a) of the eyelet used in the mechanism of this embodiment and its A-A sectional view (b), image 3 (a), (b) are views showing the sealing structure of this embodiment.

[0020] The sealing structure of the present embodiment is related to when several (six in the case of this embodiment) oil pressure hoses (PPC hoses) 1 and one electrical wiring harness 2 are passed through the ground of the cab. The sealing structure of the control lever installed in the cab of the hydraulic excavator includes an eyelet 4 that is engaged with and fixed to a through-hole 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com