Absorbent articles having fiber layer on its surface

An absorbent and fiber layer technology, applied in absorbent pads, layered products, fabrics, etc., can solve the problems of easy retention of liquid, reduce contact area, and difficulty in making the skin non-irritating, and achieve the effect of reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

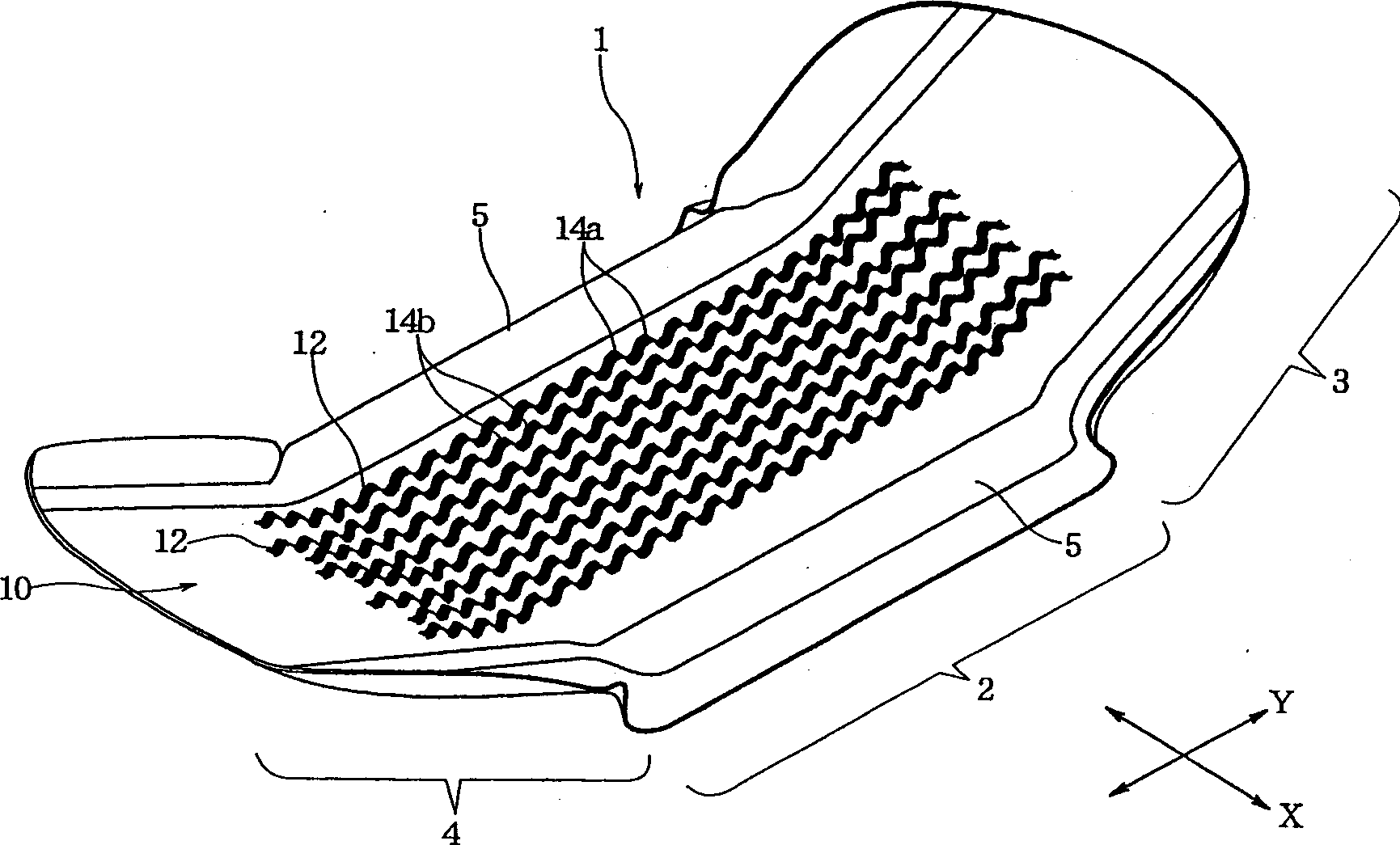

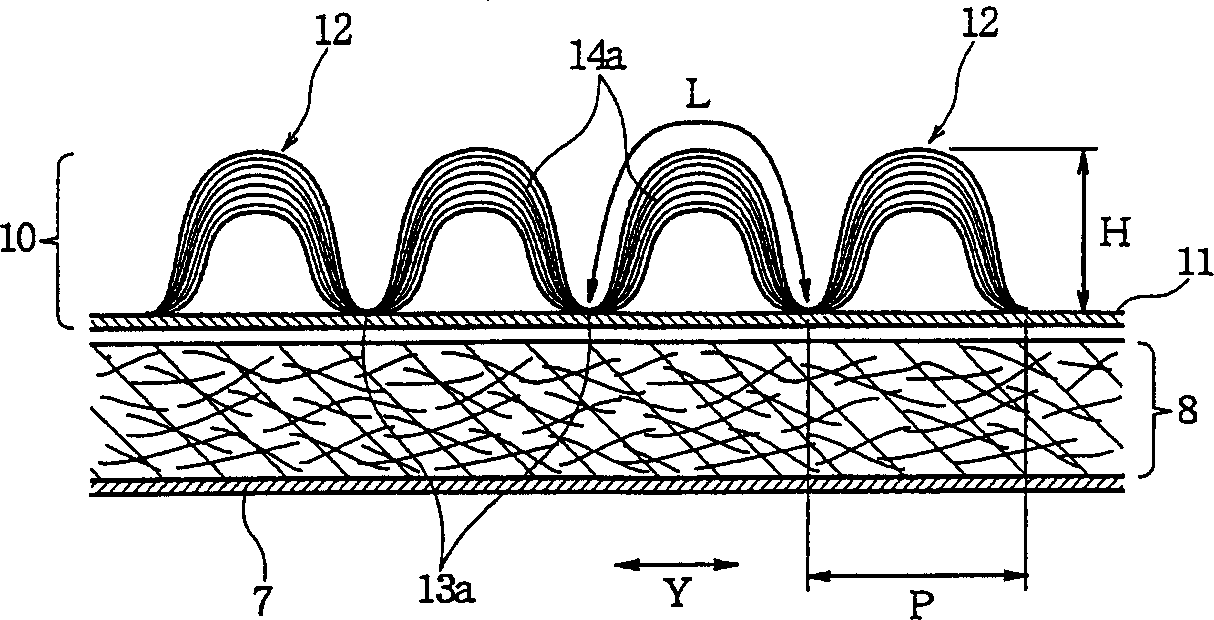

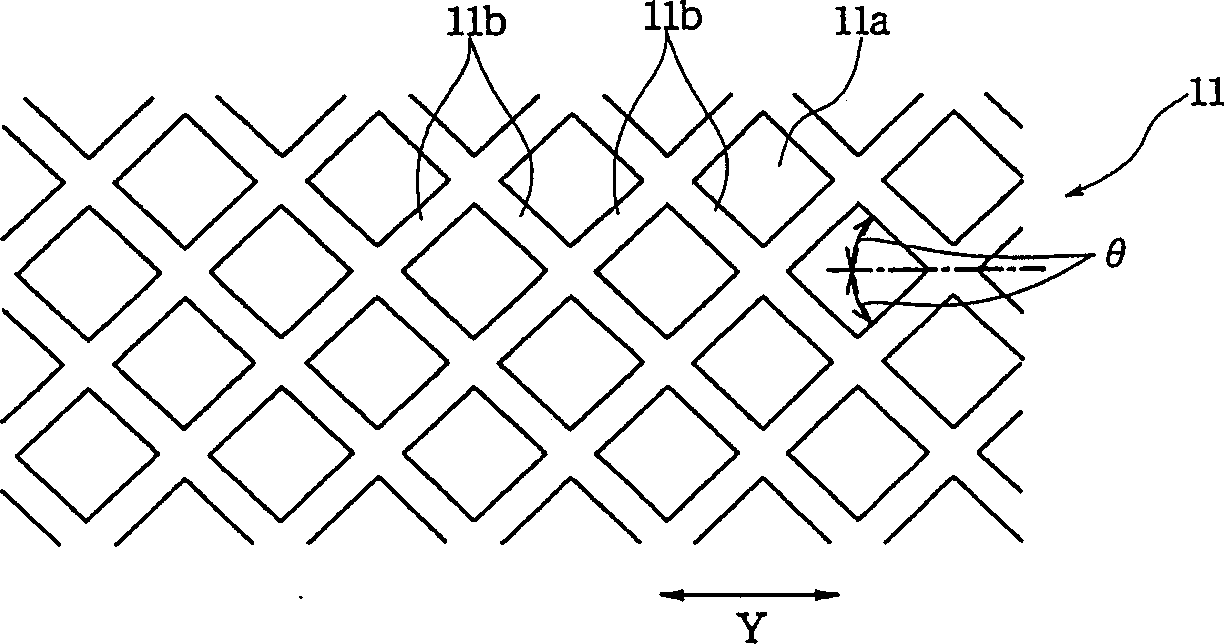

[0028] figure 1 To show a perspective view of a first embodiment of an absorbent article of the present invention, figure 2 Its partial section view, image 3 with Figure 4 To show an enlarged plan view of an example of an apertured film, Figure 5 ~ Figure 8 a partial top view of a joint pattern showing jointed fiber layers, Figure 9 to have Figure 8 A partial cross-sectional view of the absorbent article in the joint portion mode.

[0029] figure 1 The absorbent article 1 shown is a sanitary napkin, the X direction is the width direction, and the Y direction is the longitudinal direction. This absorbent article 1 has an intermediate portion 2 and sandwiches a front portion 3 and a rear portion 4 of the intermediate portion 2 . Leakage prevention walls 5, 5 extending in the longitudinal direction (Y direction) are provided on both sides of the absorbent article 1 . Elastic members capable of exerting an elastic contraction force in the longitudinal direction are i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com