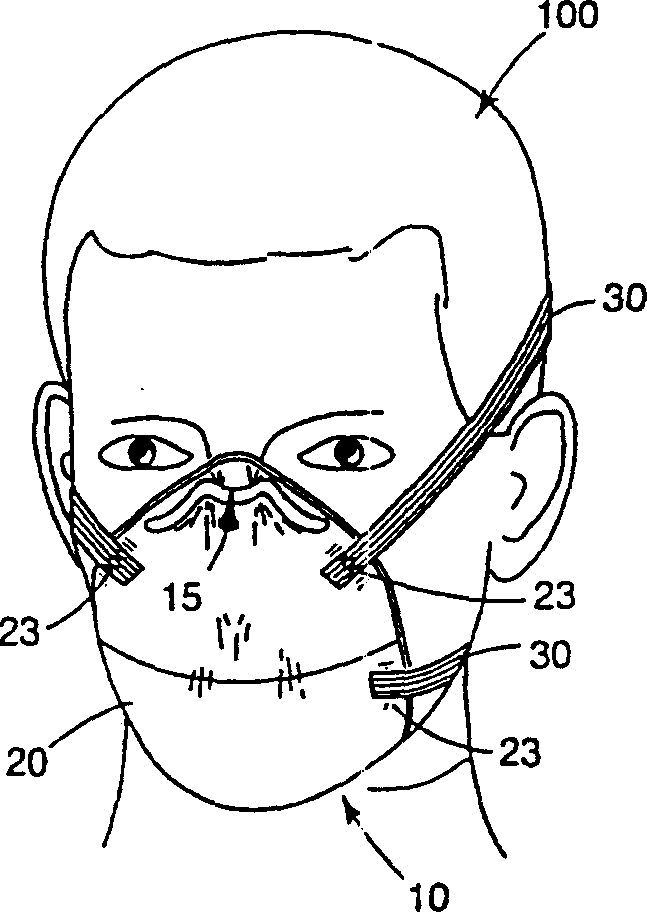

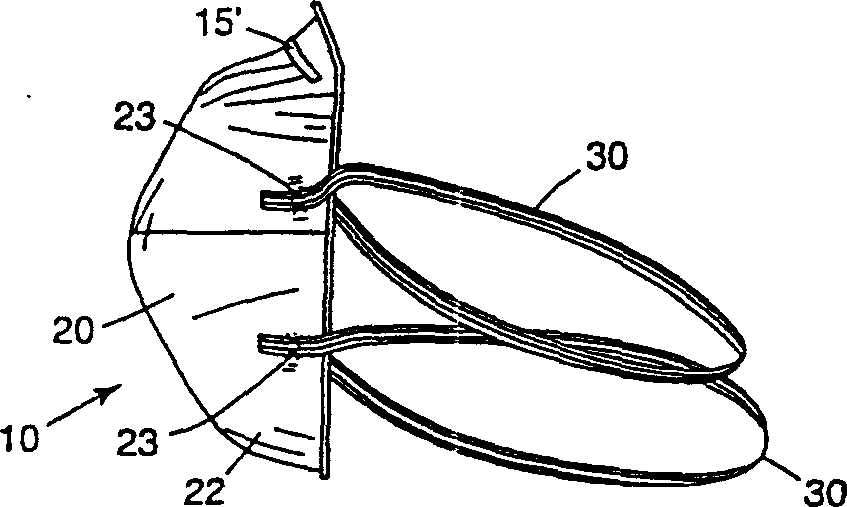

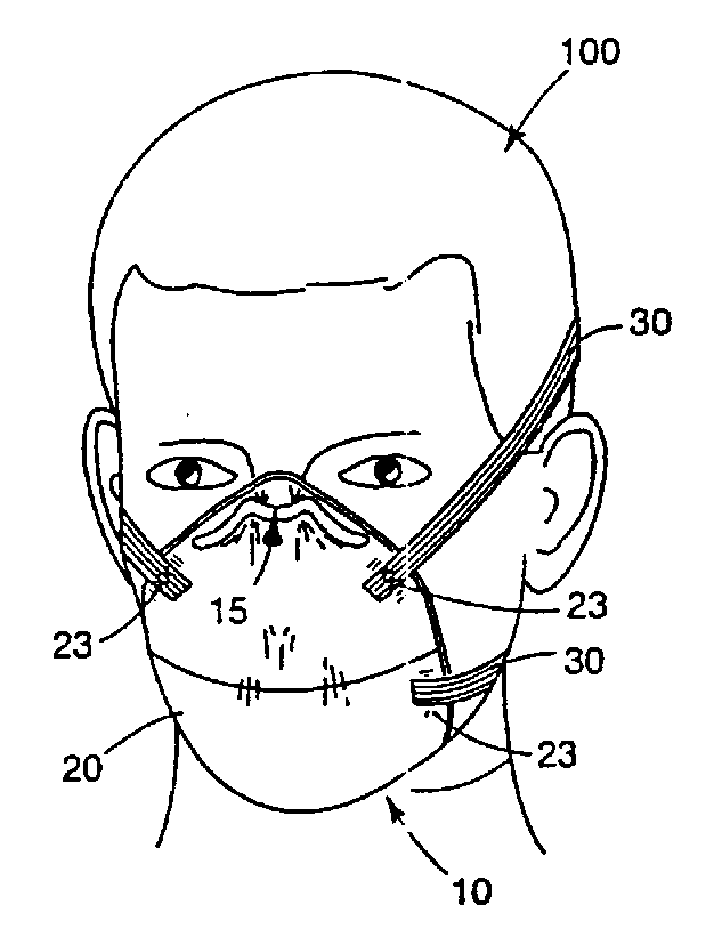

Face masks having an elastic and polyolefen thermoplastic band thereto by heat and pressure

A polyolefin and thermoplastic technology, applied in the field of preparing filter masks, can solve the problem of not being able to filter air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Composite straps are sonically welded to a variety of conventional filtering mask bodies. The sonic welder used was a Branson 501 sonic welder with 1170P controller. The shim (or the part of the welder that is in contact with the weld zone) is provided with a 14.5mm x 9.8mm contact zone with a plurality of 0.5mm protrusions at 0.7mm spacing and 0.7mm height. For welding, place the straps in the desired location on the mask body and place the shims on the straps. The shim is slightly larger than the width of the straps so that it overlaps the mask body. The shim is made to vibrate for a certain period of time (welding time), during which time heat is generated. After soldering, the shim remains in the weld zone (hold time) to secure the solder bond.

[0060] The following conventional filtering masks were used as the mask body in this example:

[0061] "8210" is an 8210 trademark filtering mask available from 3M Company in the United States, which has a molded shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com