Coke-receiving, core-quenching and coke-discharging equipment for horizontal coke-oven

A coke oven and horizontal technology, which is applied in the field of unloading devices of coke ovens, can solve the problems of occupying process area, inability to complete the opening and closing operations of the upper and lower furnace doors, and increasing investment, so as to save engineering investment and reduce costs. The effect of height difference, saving investment and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

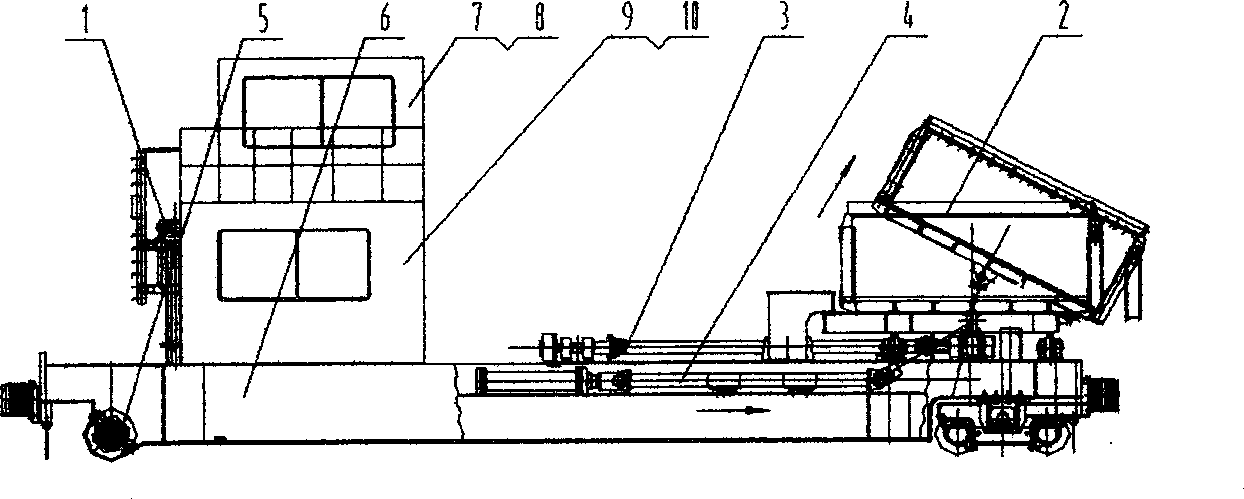

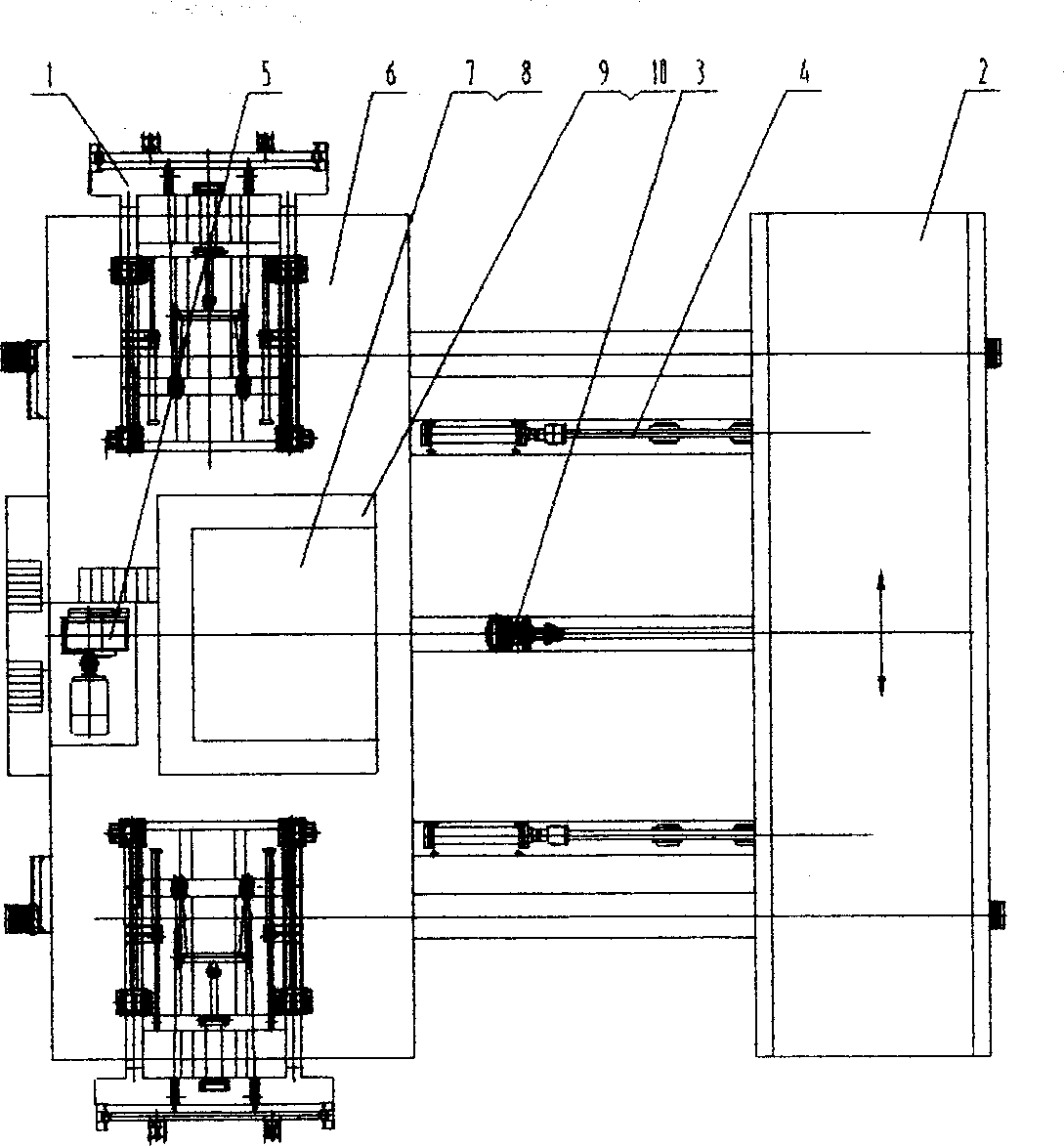

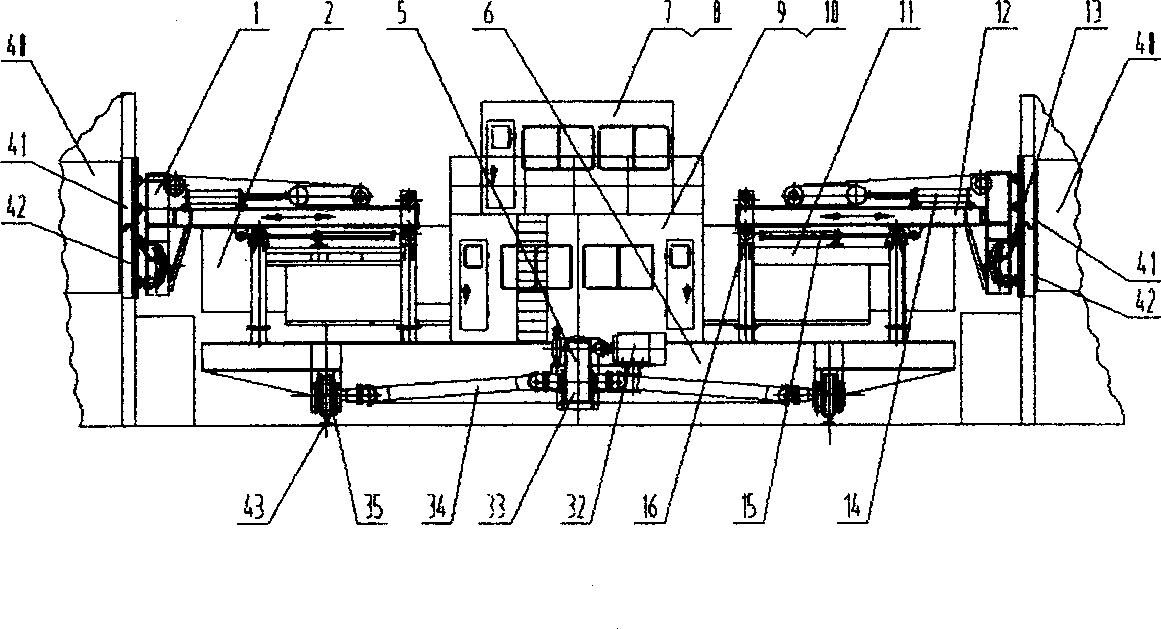

[0018] like figure 1 , figure 2 , image 3 As shown, a device suitable for coke receiving, coke quenching and coke unloading in a horizontal coke oven consists of a furnace door opening and closing mechanism 1, a coke receiving trough 2, a coke receiving trough translation mechanism 3, a coke trough tilting mechanism 4, Cart running mechanism 5, frame body 6, driver's cab 7, electrical room 8, hydraulic station 9, compressed air station 10 and other parts. Two sets of furnace door opening and closing mechanism 1, cart operating mechanism 5, driver's cab 7, electrical room 8, hydraulic station 9, and air compressor station 10 are installed on one side of the frame 6, and the other side of the frame body 6 is connected Focus slot 2.

[0019] There are two sets of furnace door opening and closing mechanisms 1 in the present embodiment, and the equipment can be front and rear two rows of coke ovens 40 opening and closing furnace doors. like image 3 Shown: the furnace door o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com