Strippable film

A film and copolymer technology, applied in the field of easy-peeling film, can solve the problems of insufficient adhesion and peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

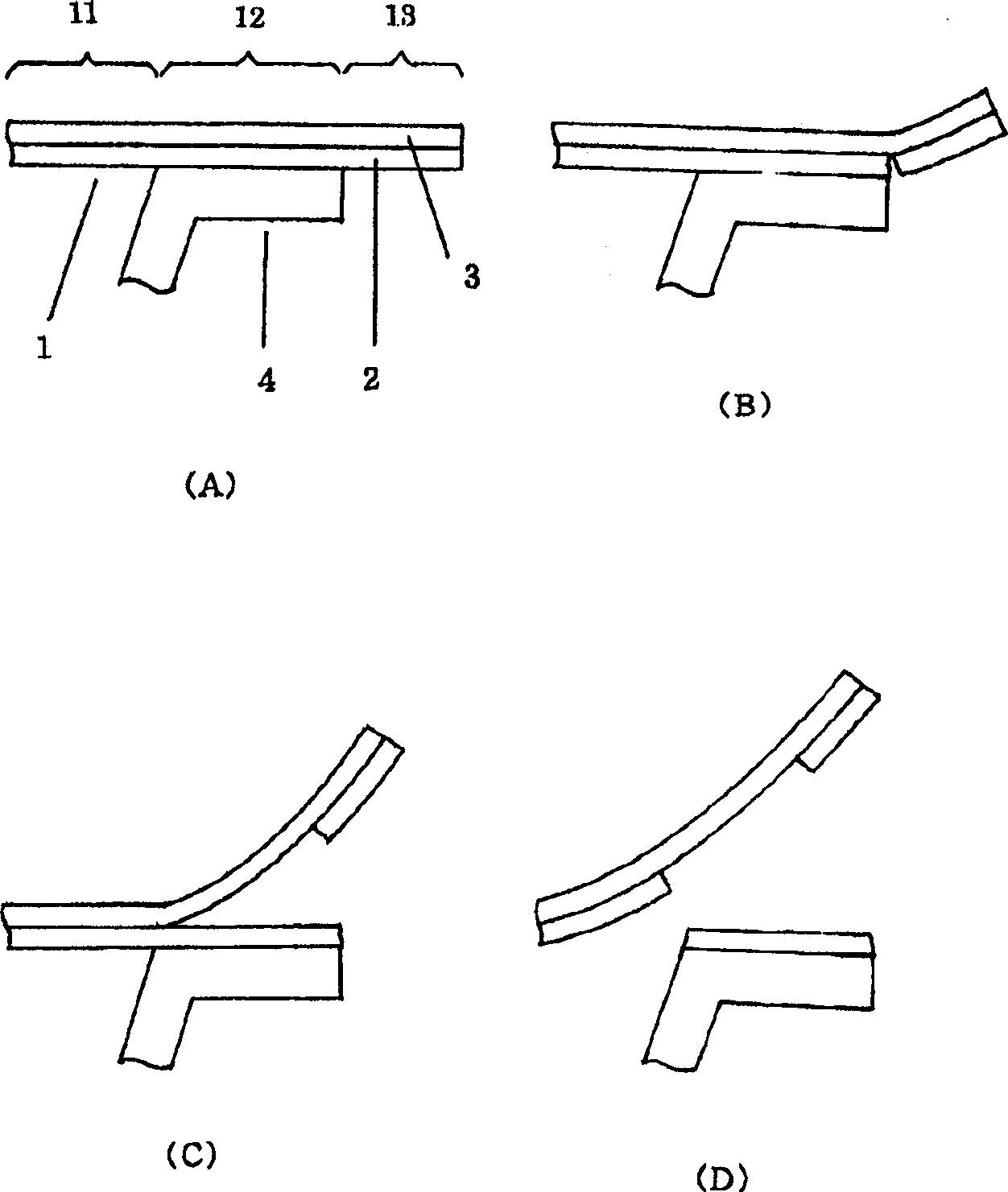

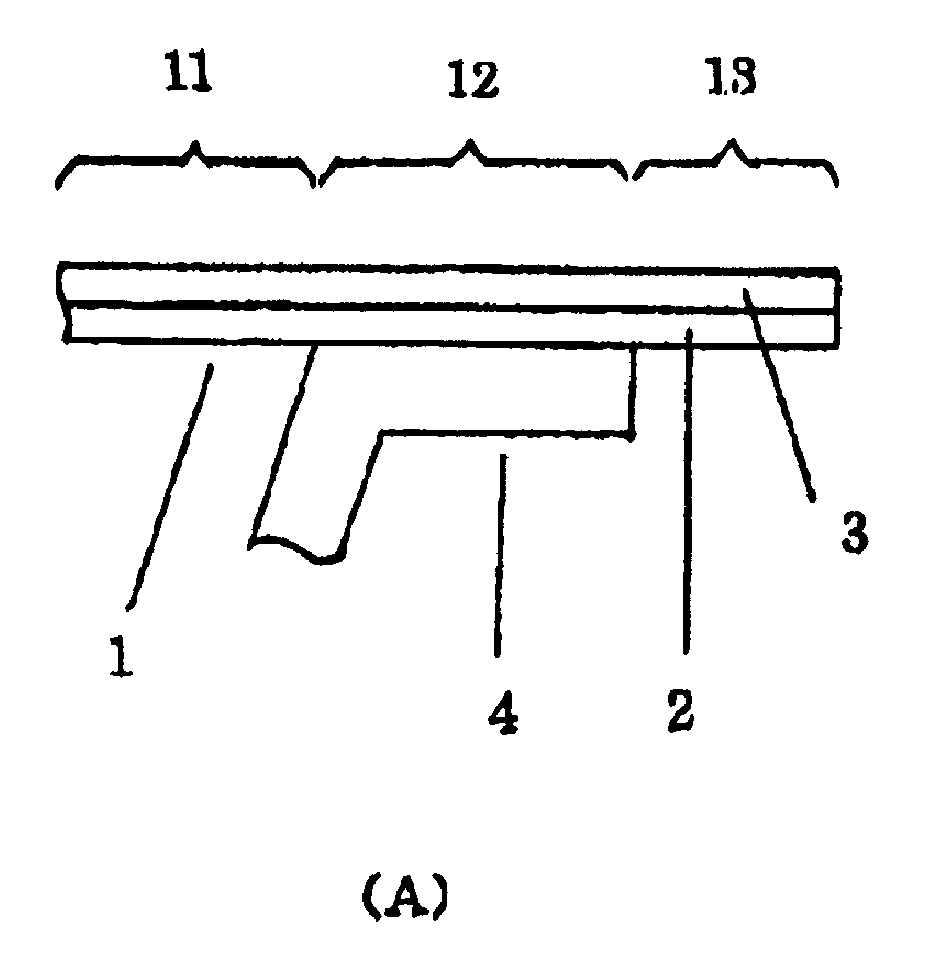

Image

Examples

Embodiment 1

[0039] Terephthalic acid / ethylene glycol / cyclohexanedimethanol terpolymer (manufactured by Eastman Chemical Co.: PHTG6763) was used as the sealing layer, while ethylene / methyl acrylate copolymer (manufactured by Sumitomo Chemical Co., Ltd., Acryft CG4002, ethylene content 69 wt%) was used as the ethylene copolymer layer adjacent to the sealing layer. In addition, an ethylene / vinyl acetate copolymer (manufactured by Sumitomo Chemical Co., Ltd.: Evatate T3022, ethylene content 93 wt%) is used as a layer between the sealing layer and the ethylene copolymer layer, which plays a role of connecting the two layers (later referred to as the lamination layer). These three resins are co-extruded with a three-layer co-extrusion T-die manufactured by Chugai Tec K.K. so that the thickness of the sealing layer, ethylene copolymer layer, and lamination layer are 5 μm, 10 μm, or 20 μm, respectively, and they become laminated film.

[0040]Thereafter, the exposed surface of the laminated lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com