Surface gradient protective coating and its preparing method

A protective coating and surface gradient technology, applied in the field of surface gradient protective coating and its preparation, can solve the problems of small difference in thermal expansion coefficient, difficulty in spraying materials, unfavorable practical application, etc., achieve good matching, and improve stress crack resistance and peeling ability, excellent corrosion resistance of high aluminum zinc melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

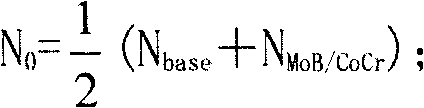

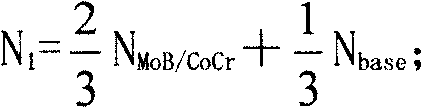

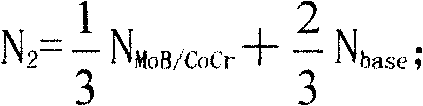

[0009] The sample size is Φ70mm×300mm, and the material is steel 316L for hot-dip high-aluminum-zinc sinking roller / stabilizing roller. As the thermal expansion coefficient of the MoB / CoCr surface protection working coating is smaller, the poorer the matching between the coating and the roll material is, and the coating is more likely to crack and peel off; for this reason, the thermal expansion coefficient N is selected in this case MoB / CoCr =9.0×10 -6 / K's MoB / CoCr cermet is used as a surface protection working coating material. When using a buffer transition layer, N 0 = 1 2 ( N 316 L + N MoB / CoCr ) ≈ 14.0 × 10 - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com