Electrically controlled hydraulic vehicle with individual drive and brake of wheels and recovery of braking energy

A technology for recovering braking and independent driving, applied in the field of vehicles, can solve problems such as high cost and complexity, and achieve the effects of reducing self-weight, simplifying structure, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

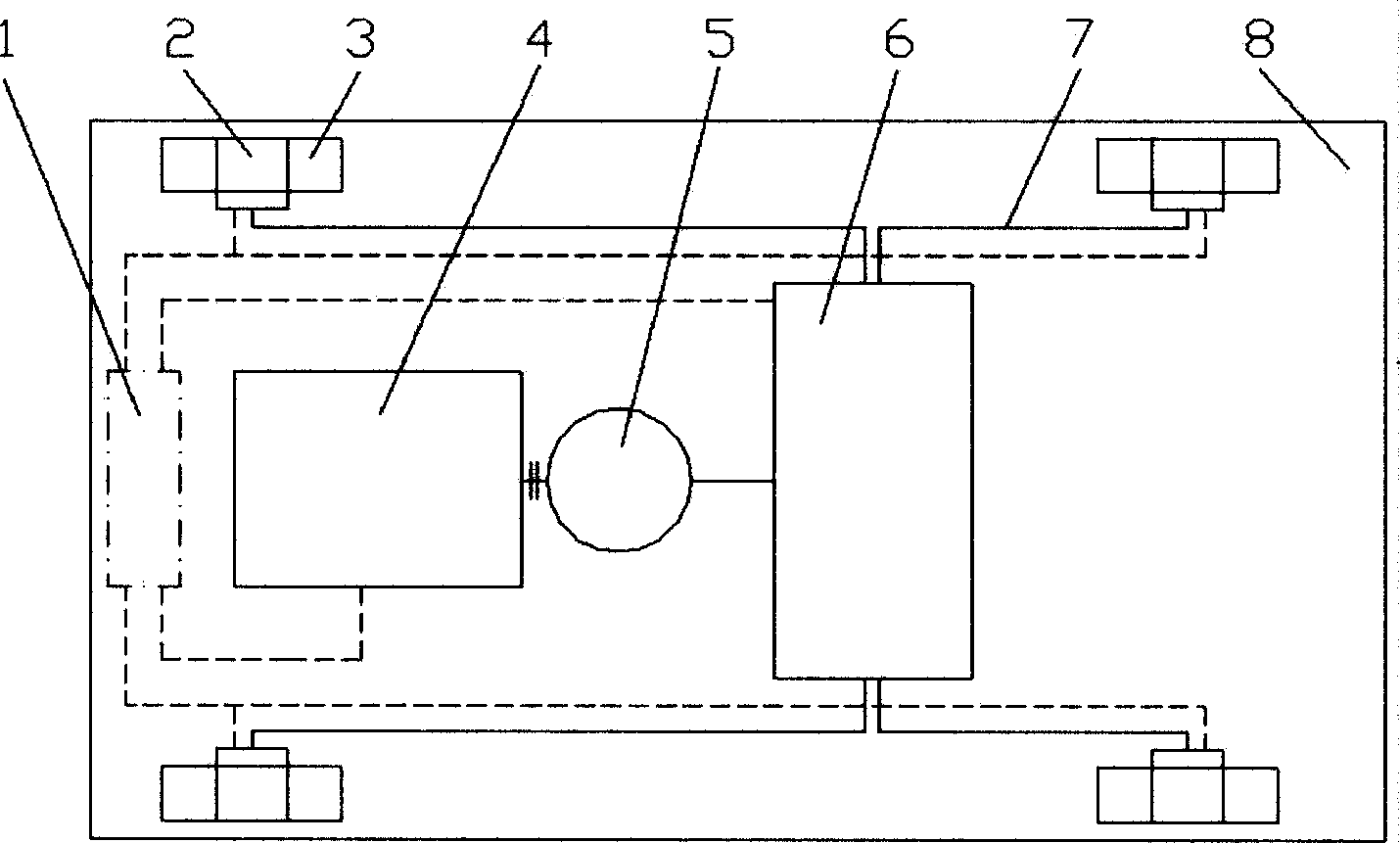

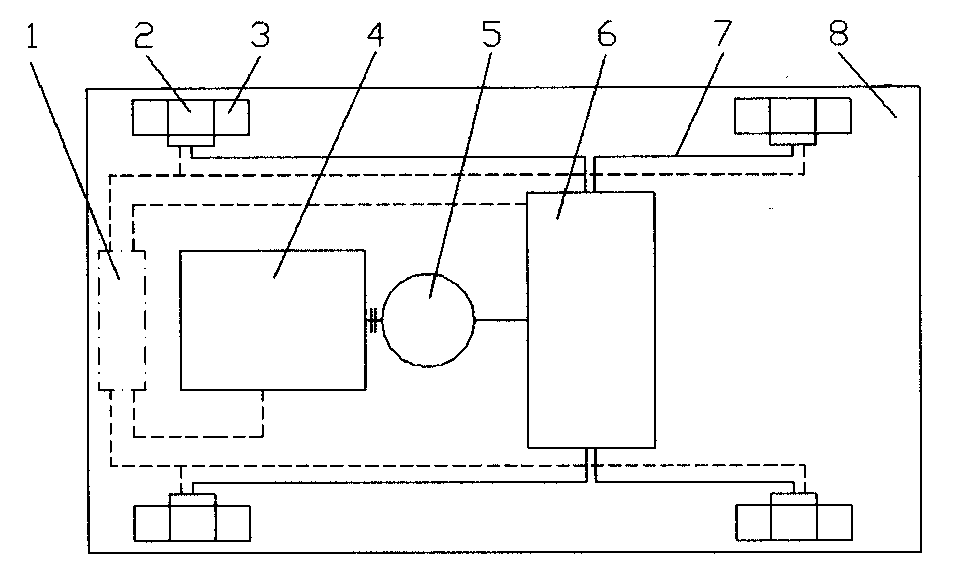

[0010] In conjunction with the accompanying drawings, the electronically controlled hydraulic drive bus of the present invention, which independently drives the brakes and reclaims the braking energy, is characterized in that: engine 4 (diesel engine is selected for use), hydraulic accumulator 6 (air bag type hydraulic accumulator is selected for use) etc. are installed on the frame, each wheel 3 is provided with a two-way variable hydraulic motor 2, the engine 4 is connected with the hydraulic pump 5 (selection of quantitative pump), and the hydraulic pump 5 and each hydraulic motor 2 (selection of two-way variable hydraulic motor) are respectively Connected to the hydraulic accumulator 6 through the hydraulic pipeline 7, the electronic control unit 1 receives sensor signals such as the wheel angular velocity, the position of the accelerator pedal, the position of the brake pedal, the engine speed, the pressure of the hydraulic accumulator, and controls the operation of the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com