Forming method for arficial limb receiving chamber and inner lining tube

A socket and tube-forming technology, which is applied in the direction of artificial legs, etc., can solve the problems of expensive imported elastic soft plastic, high cost, frequent replacement, etc., and achieve the effects of reducing economic burden, benefiting environmental protection, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

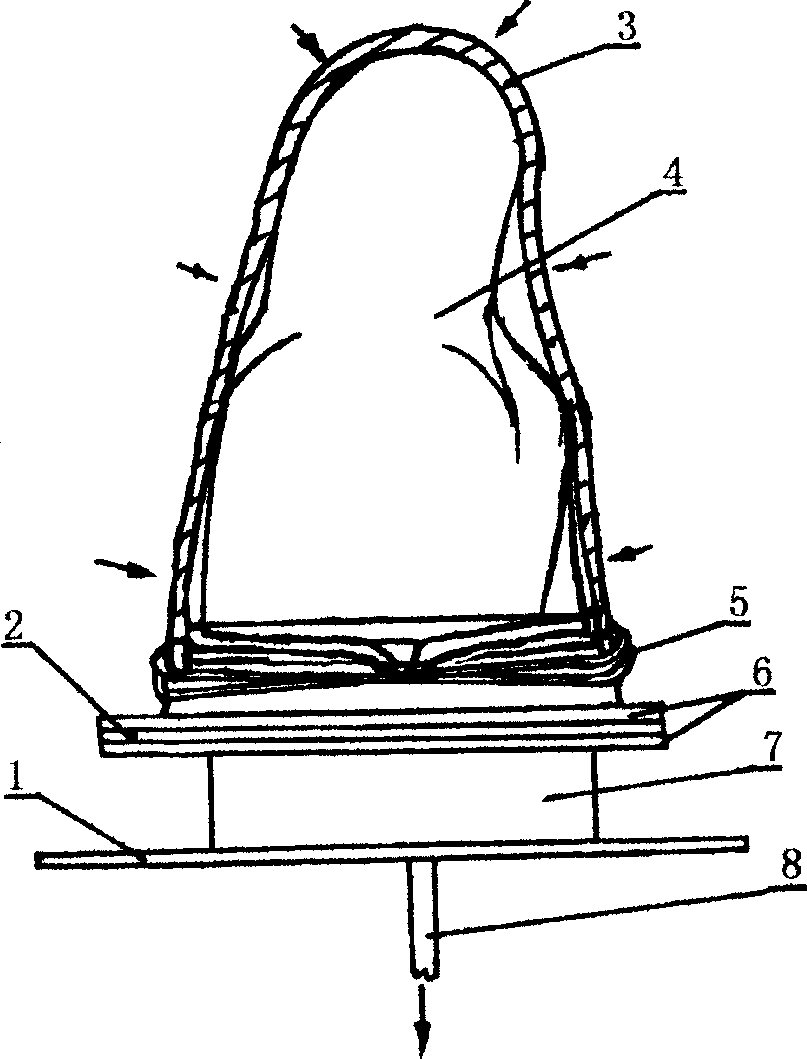

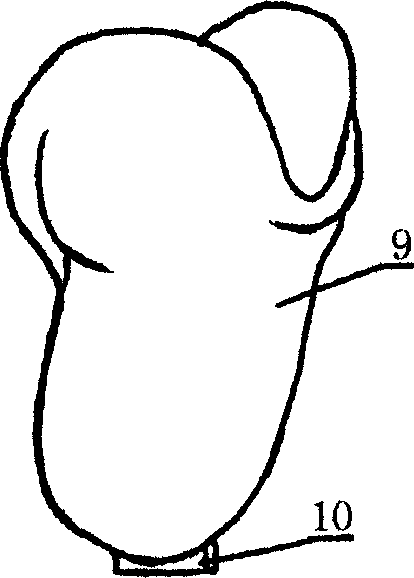

[0016] figure 1 Shown is the schematic diagram of the forming equipment of the prosthetic receiving cavity and the inner lining forming method. The shape of the prosthetic receiving cavity and the inner lining into the cylinder of the present invention is the same, but one is hard plastic and the other is soft plastic. It is to first press the plastic into a cylindrical blank 3 to be made into another part, and then put it into a special oven and heat it to the softening temperature of the plastic. The softened plastic tube blank 3 is closely attached to the surface of the male mold 4. After cooling, it is processed into a finished product shape according to the drawing. The production process is as follows:

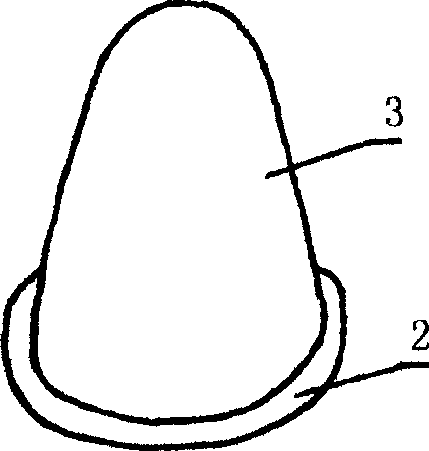

[0017] 1). Select the appropriate tube blank 3 (such as image 3 shown);

[0018] 2). Cut a section of cotton yarn sleeve to cover the edge 2 of the bottom blank 3 of the tube, then clamp the special clamp 6 on both sides of the edge 2, and press it with fixing screws;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com