Analyzing cartridge and liquid feed control device

一种液体、溶液的技术,应用在分析盒领域,能够解决喷嘴堵塞、污染、结构复杂等问题,达到减少限制、简单内部结构、低廉生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0307] (Experimental example 1: Measurement of the backwater pressure of the hydrophobic membrane)

[0308] Backwater pressure is measured for each average pore size of hydrophobic membranes of various materials. For the laboratory setup for the measurements, the setup in which the removable filter holder 810 with the membrane 800 is placed is connected to the tip of a syringe 820 with an internal diameter of 5 mm. The effective diameter of membrane 800 is 3 millimeters. In addition, in the attached Figure 10 Figure (b) in FIG. 1 shows a cross-sectional view of the filter holder 810 and the tip of the syringe 820.

[0309] To measure backwater pressure, the syringe 820 is first placed in the test solution 830, and the measurement is taken by pushing the syringe 820 against the dial 840 while the syringe 820 is held upright with its tip pointing up. The air in the syringe 820 is pushed to the outside through the membrane 800 , by pushing the syringe further to gradually inc...

example 2

[0371] Another example of quantitative analysis of total cholesterol in serum performed using the same cartridge as that in Example 1 will now be described. However, in this example, an air pressure method is applied as a method of transferring liquid.

[0372] As for the analysis box 5, except that electrodes and lead wires are not provided, the same analysis box as that used in the accompanying drawings 11, 12 and 13 (Example 1) is applied, so this example will be described using the accompanying drawings 11, 12 and 13 . In addition, various operations and procedures are also almost the same as those in Example 1, so only analysis procedures that are different from Example 1 will be described below.

[0373] to 3)

[0374] The procedure is the same as that of the example.

[0375] 4) Preparation of reagent solution

[0376] The procedure is the same as that of the example, but the operation of wetting the tank m is not carried out.

[0377] Filtration and measurement of...

example 3

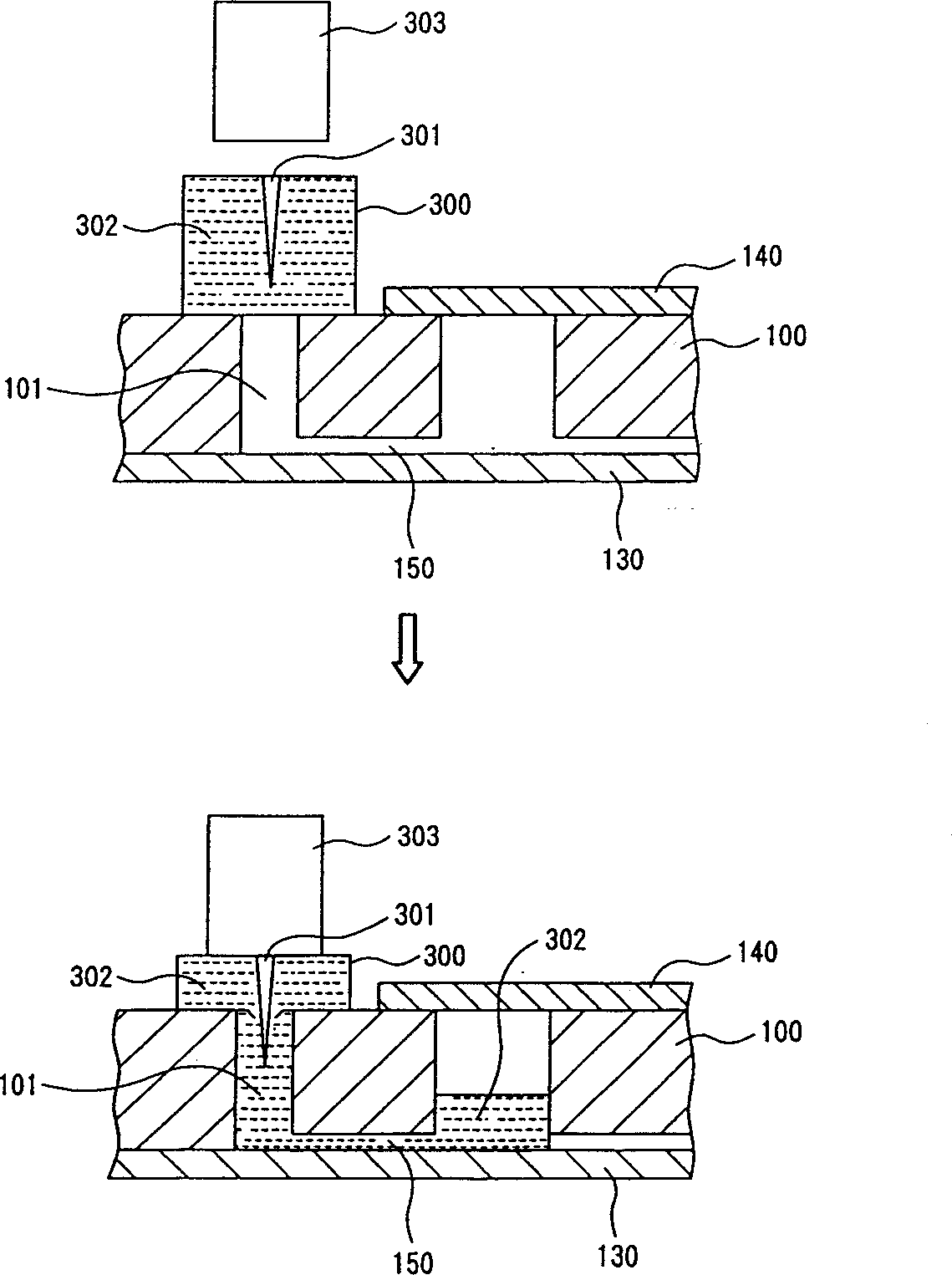

[0384] The method of manufacturing the cartridge 4 as described above and the method of dissolving the reagents in the cartridge 4 are described in detail below.

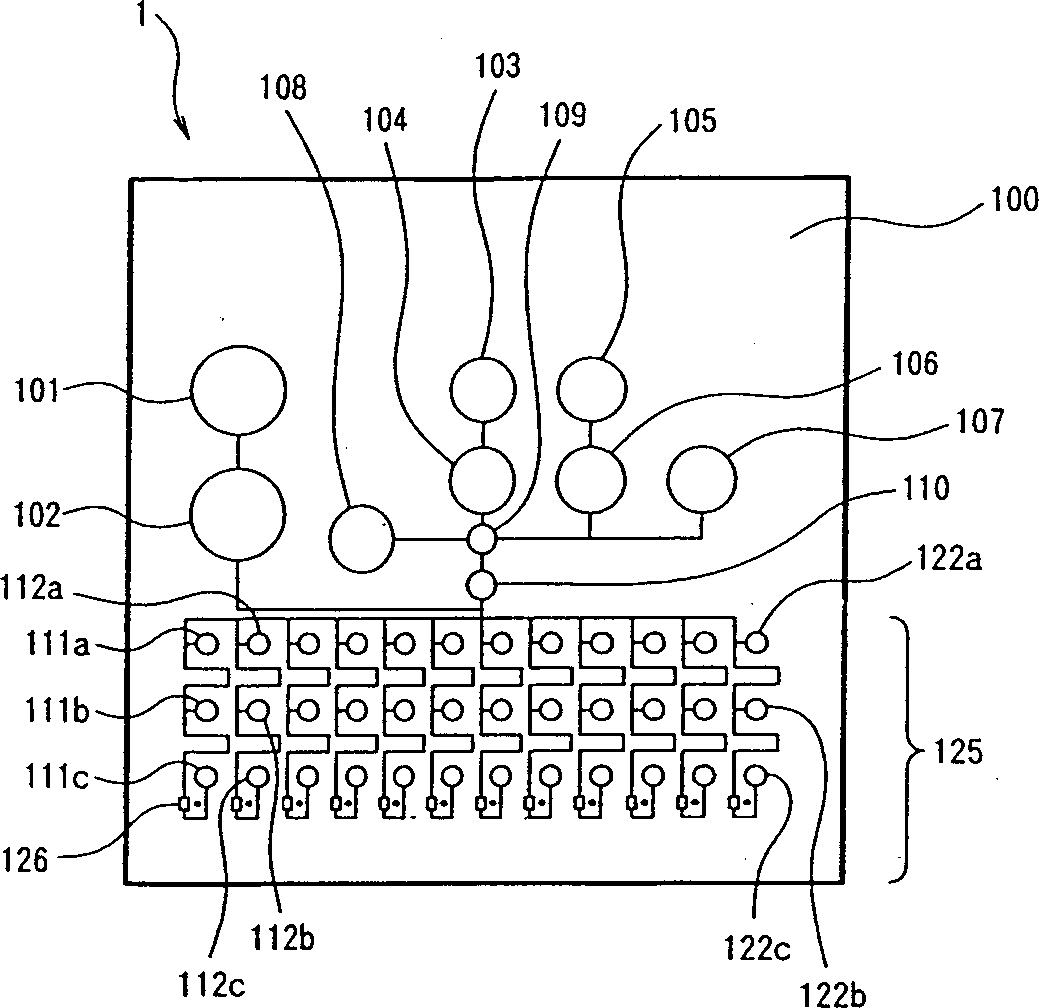

[0385] Description of planar component 900

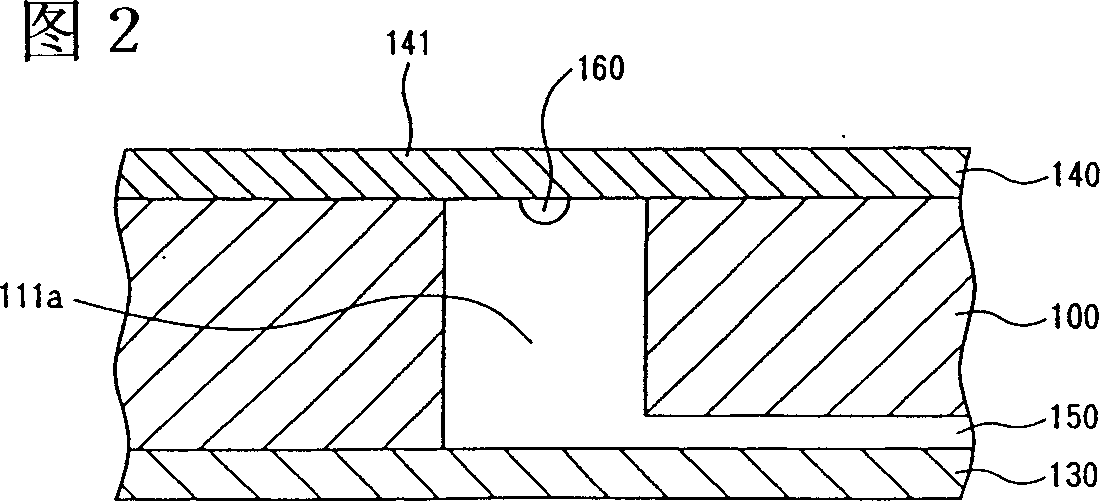

[0386] Injection molding using PMMA resin was performed to form the planar member 900 constituting the analysis cartridge 4 . This planar part 900 is 2 mm thick and has the attached figure 1 Model of the slot shown. The width and depth of the grooves a to m are both 50 micrometers. And, it comprises a well with a diameter of 2 mm and a depth of 50 micrometers, which constitutes the measuring conduit A. In addition, it has through holes each having a diameter of 2 mm, which constitute the containers 901 to 912 .

[0387] 2) Squeeze the exhaust film

[0388] Using a ring die with an outer diameter of 4 mm and an inner diameter of 3 mm (1 mm in width), the PTFE porous membrane membrane 940 was extruded to remove the porosity of the extruded part. Squeezing is performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com