Intelligent ink cartridge and its manufacture

A manufacturing method, technology of ink cartridges, applied in printing, measuring device, measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] exist Figure 10 , a block diagram of the scheme is shown. In this embodiment, in order to increase ink capacity x%, the simplest method is:

[0049] Step 100 includes the following steps:

[0050] When the power is turned on or the ink cartridge is installed in the inkjet printing device and moved to the normal position, the ink consumption rate data stored in the EEPROM is sent to a first register of the microcontroller, and its ink consumption rate is temp1;

[0051] After receiving the control signal of the inkjet printing device, the ink consumption rate is transmitted from the first register to the side of the inkjet printing device for storage;

[0052] After finishing the printing job, update the ink consumption rate;

[0053] When the inkjet printing device is powered off or when the ink cartridge storage bin is moved to the installation position, the updated ink consumption rate written into the ink cartridge from the inkjet printing device side is stored i...

Embodiment 2

[0061] In order to overcome the design limitations in Embodiment 1, in Figure 11, the implementation steps are improved as follows:

[0062] Step 201, use the software flag (adj) stored in the EEPROM of the ink cartridge electronic module to identify whether the microcontroller has adjusted the ink consumption rate, and use the initial value '0' to indicate that it has not been adjusted;

[0063] When the printer is powered on, when receiving a power signal from the printer or installing an ink cartridge, the ink consumption rate register reg1 stored in the EEPROM is sent;

[0064] According to the control of the printer, when the printer is powered on, the ink consumption rate is sent from reg1 to the printer immediately;

[0065] The printer executes the printing task;

[0066] When the printer is powered off or the ink cartridge is replaced, the ink consumption rate written from the printer to the ink cartridge electronic module is stored in reg1.

[0067] Step 202, if th...

Embodiment 3

[0082] In order to overcome the limitation of the second embodiment, the present invention adopts another method to distinguish the read cycle performed immediately after the write cycle when the printer is powered off from the read cycle when the printer is powered on.

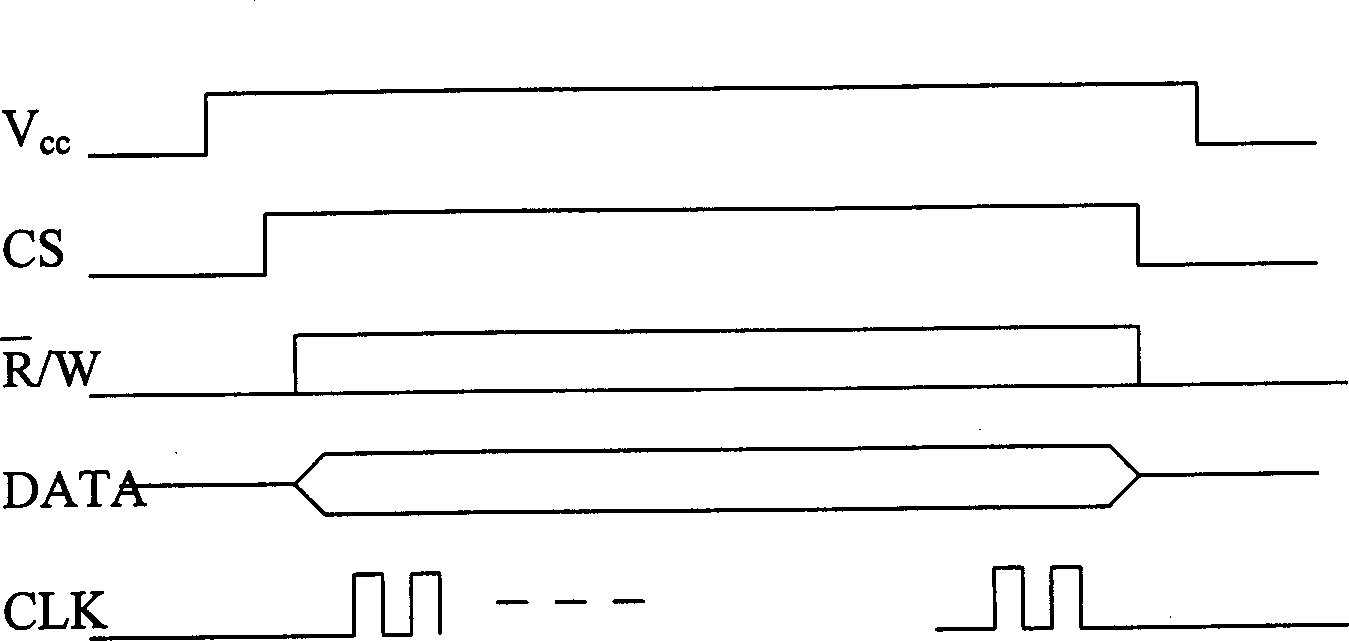

[0083] Typically, the printer checks the DC power for a read cycle (V cc ) has an interval of tens of milliseconds from the previous write cycle in time. In the read cycle when the printer is powered on, its DC power supply (V cc ) usually turns off within a few seconds or more.

[0084] Thus, an R-C circuit with a time constant of about 1 second connected to the input port (hereinafter referred to as TP1) will provide the information needed to distinguish between a detection read cycle and a normal read cycle. This can be done by at each V cc Cycle start is achieved by reading TP1. For a detection read cycle, sample TP1 is '1' and for a normal read cycle, sample TP1 is '0'. The above circuit as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com