Control valve

A technology for controlling valves and valve bodies, applied in sliding valves, valve details, multi-way valves, etc., can solve the problems of increased volume of control valves, lack of freedom, and inability to determine the opening and closing patterns of valve ports separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

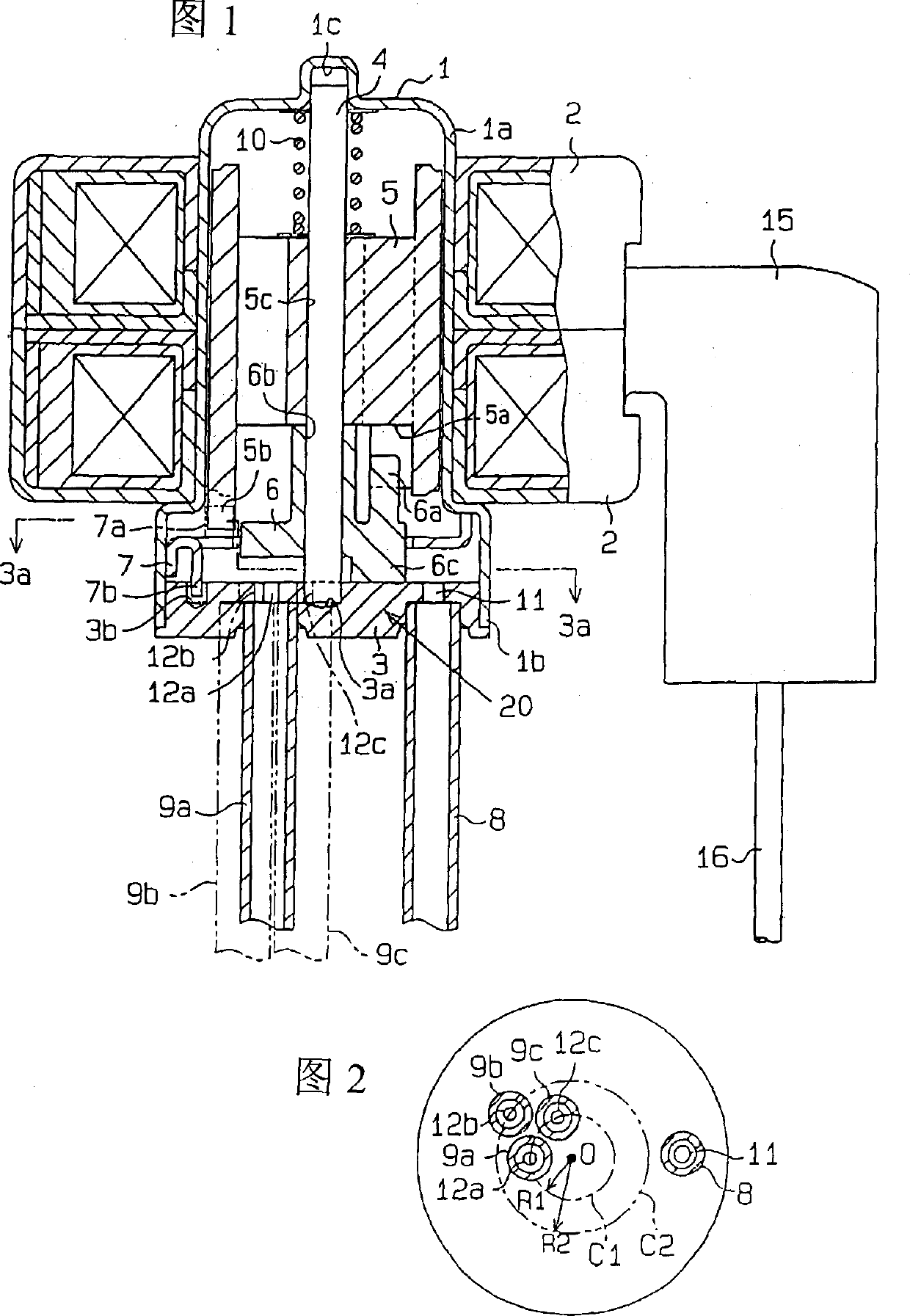

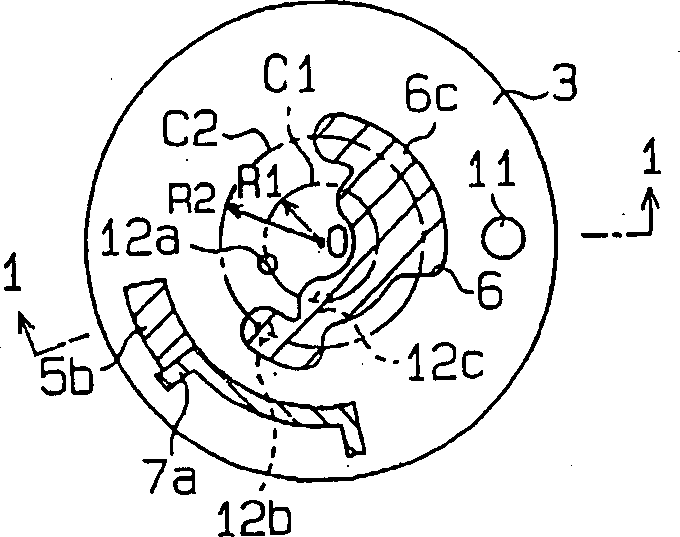

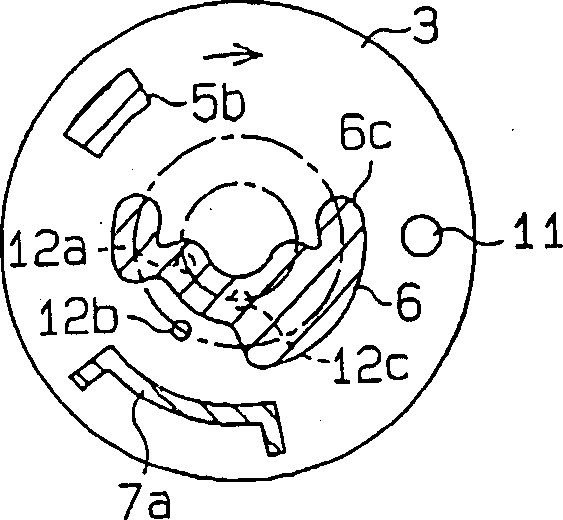

[0018] An embodiment of the present invention will be described in detail below with reference to FIGS. 1 to 4 . The control valve shown in Figure 1 is assembled, for example, in a cooling circuit (not shown in the figure) in a refrigerator, and the control valve is used to switch a plurality of refrigerant flow paths in the cooling circuit (for example, for refrigeration). circulation path and circulation path for refrigeration). The control valve includes a sealing shell 1 and a valve seat plate 3. The sealing shell 1 is cylindrical and has an opening at one end. The valve seat plate 3 is fixed to the opening end of the sealing shell 1 in a gas-tight manner. The above-mentioned sealed case 1 is formed of a non-magnetic metal. The sealed case 1 includes a smaller diameter portion 1 a, and a larger diameter portion 1 b provided near the open end of the sealed case 1 .

[0019] Around the smaller diameter portion 1a in the sealed case 1, a pair of electromagnetic coils 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com