Method and equipment for charging dried coal powder in its pressurized gasification

A technology for pressurized gasification and dry coal powder is applied in the field of dry coal powder feeding and device in the process of dry coal powder pressurized gasification, and can solve the problems of difficult operation, complex structure and low gasification efficiency of a gasifier. , to achieve the effect of stable and controllable feeding amount, simple equipment structure and reduced investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

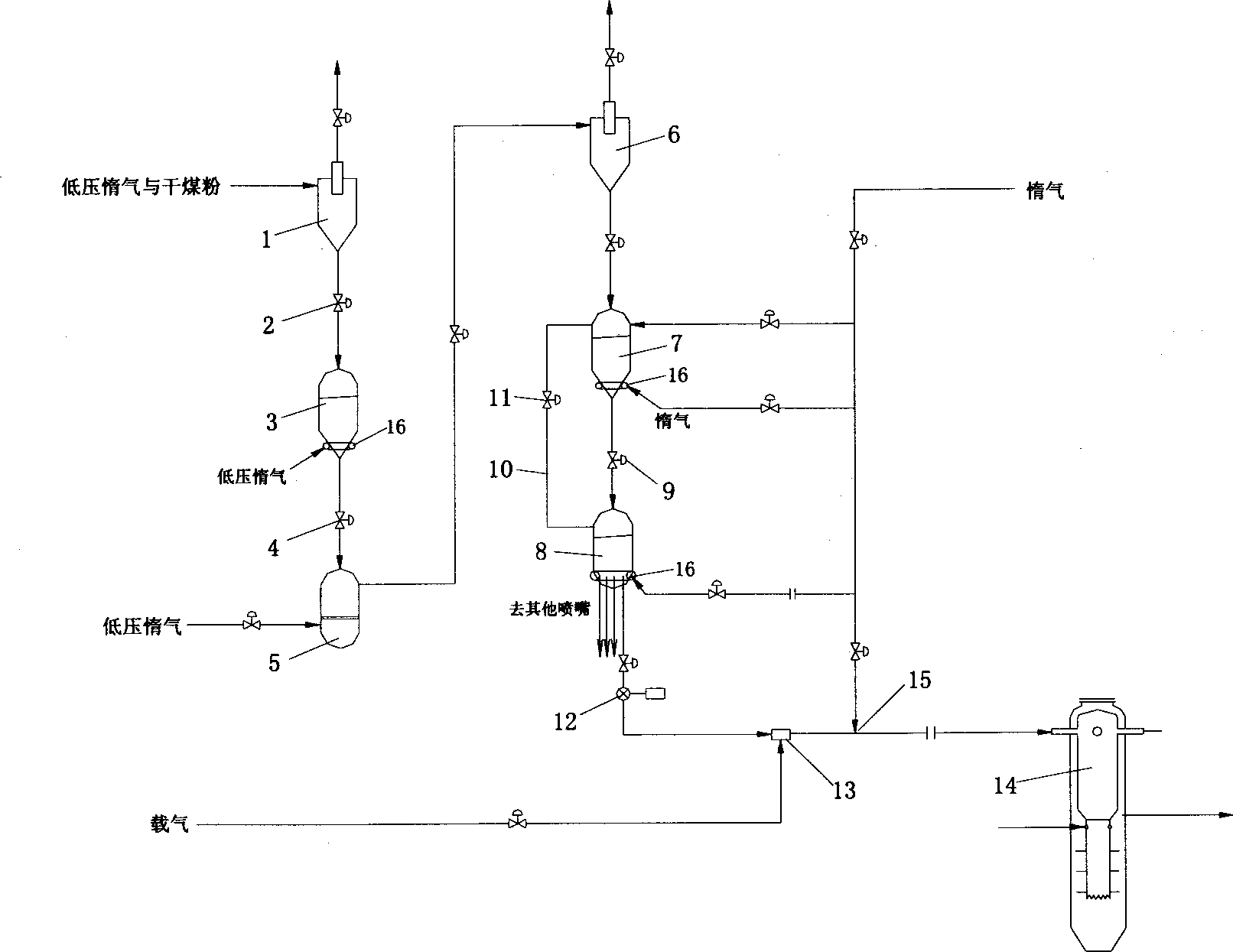

[0030] Referring to Fig. 1, method of the present invention comprises the steps:

[0031] The dry coal powder carried by the low-pressure inert gas first enters the first cyclone separator 1, and the dry coal powder enters the low-pressure powder coal bunker 3 through the pipeline at the bottom of the cyclone separator 1 for storage. emptying.

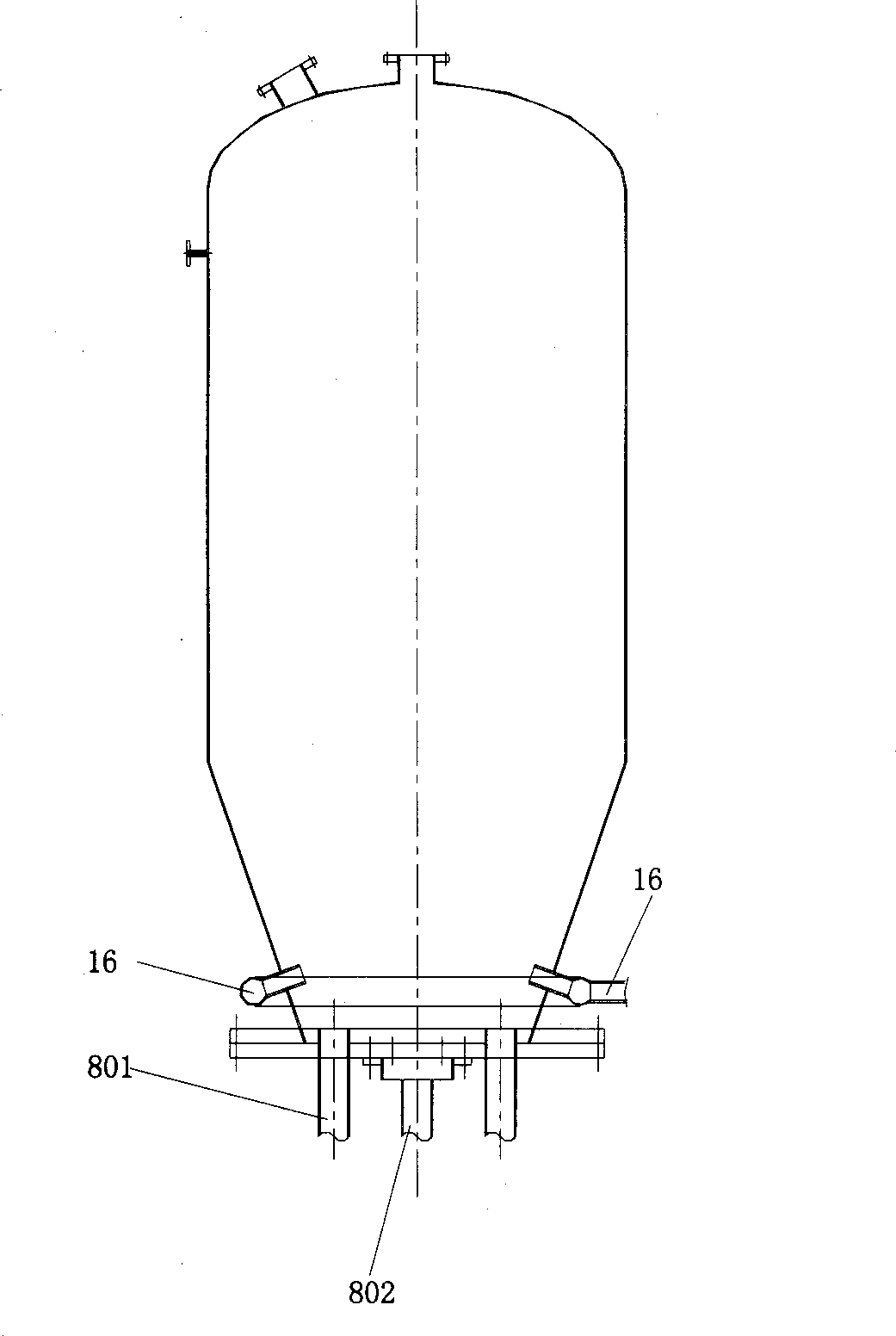

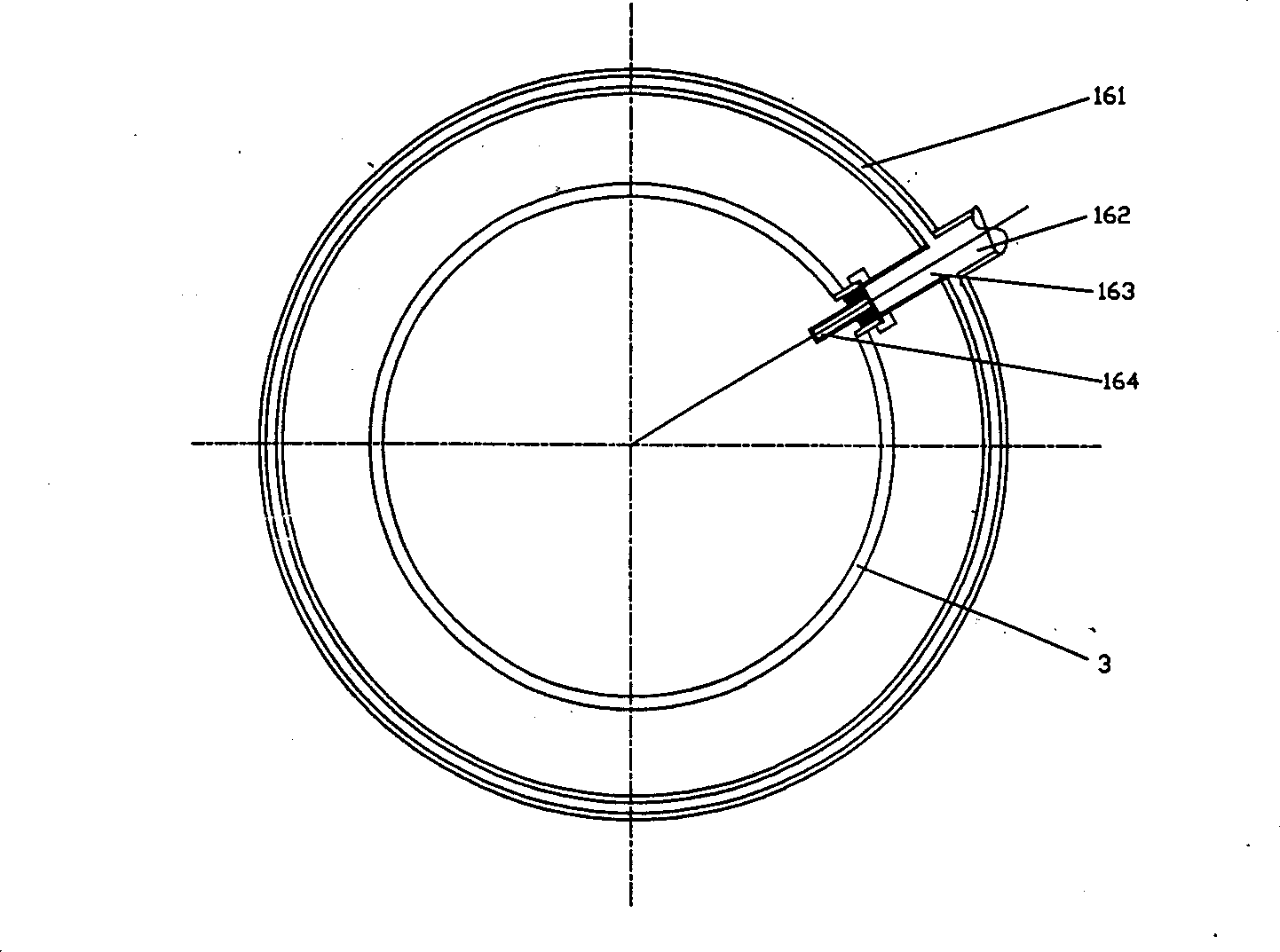

[0032] In order to prevent ratholes and bridging when pulverized coal is unloaded, inert gas is introduced into the conical surface of the low-pressure pulverized coal bunker 3 through the inert gas inlet device 16, and the low-pressure pulverized coal bunker control valve 4 set at the bottom of the low-pressure pulverized coal bunker 3 is opened , send low-pressure inert gas into the low-pressure pulverized coal bunker 3, and the pulverized coal enters the delivery tank 5 connected with it through the pipeline from the low-pressure pulverized coal bunker 3 for standby;

[0033] Close the low-pressure pulverized coal bunker control va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com