Dynamic matrix type display device having complementary capacitance on each pixel

A dynamic matrix and display device technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problem of lower aperture ratio and achieve the effect of preventing lamination and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0063] In the dynamic matrix LCD related to the first embodiment, there is a pixel portion in which each TFT is provided on a first substrate, and even a driving portion for driving the pixel portion is formed around the pixel portion on the same substrate .

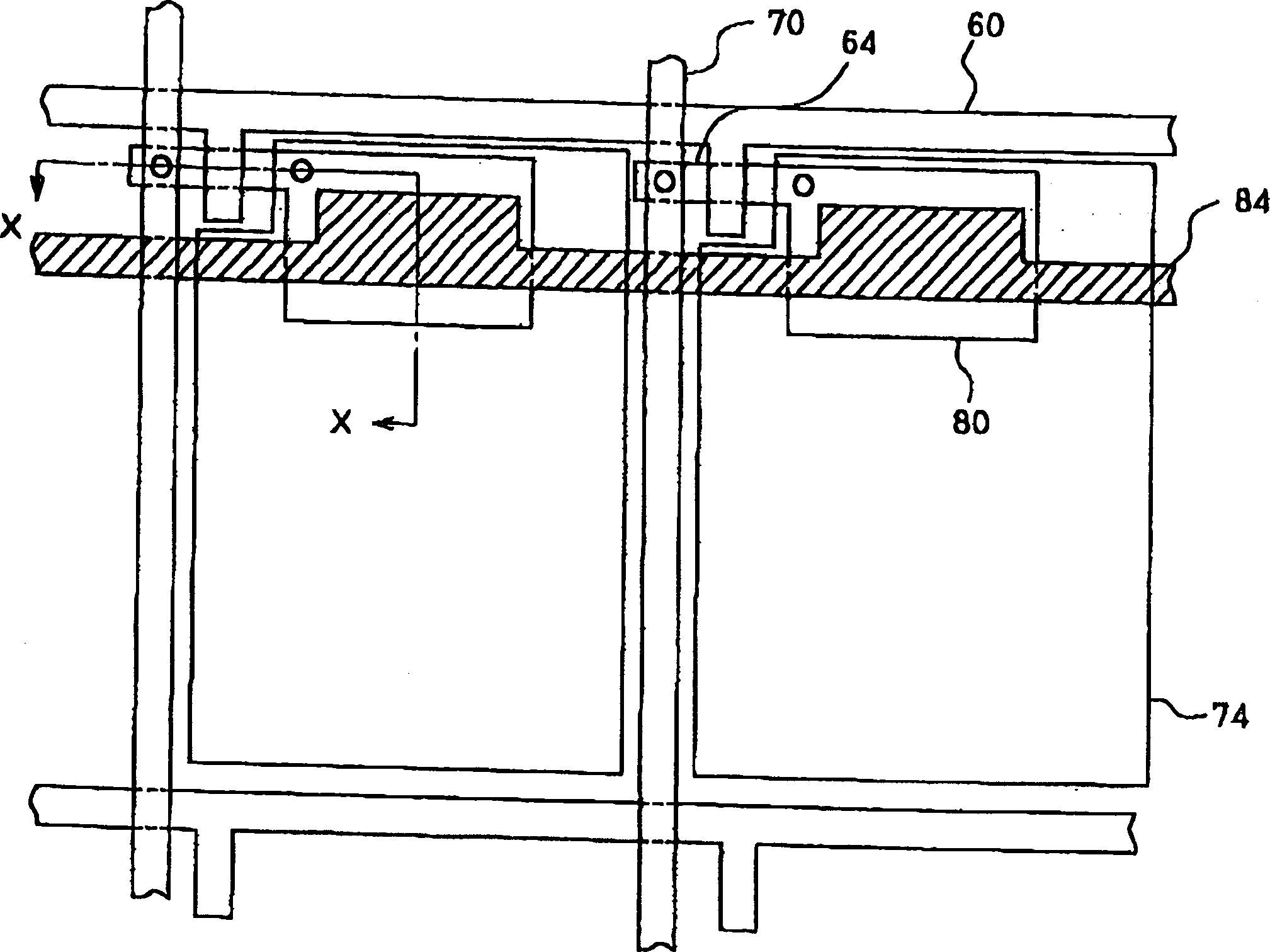

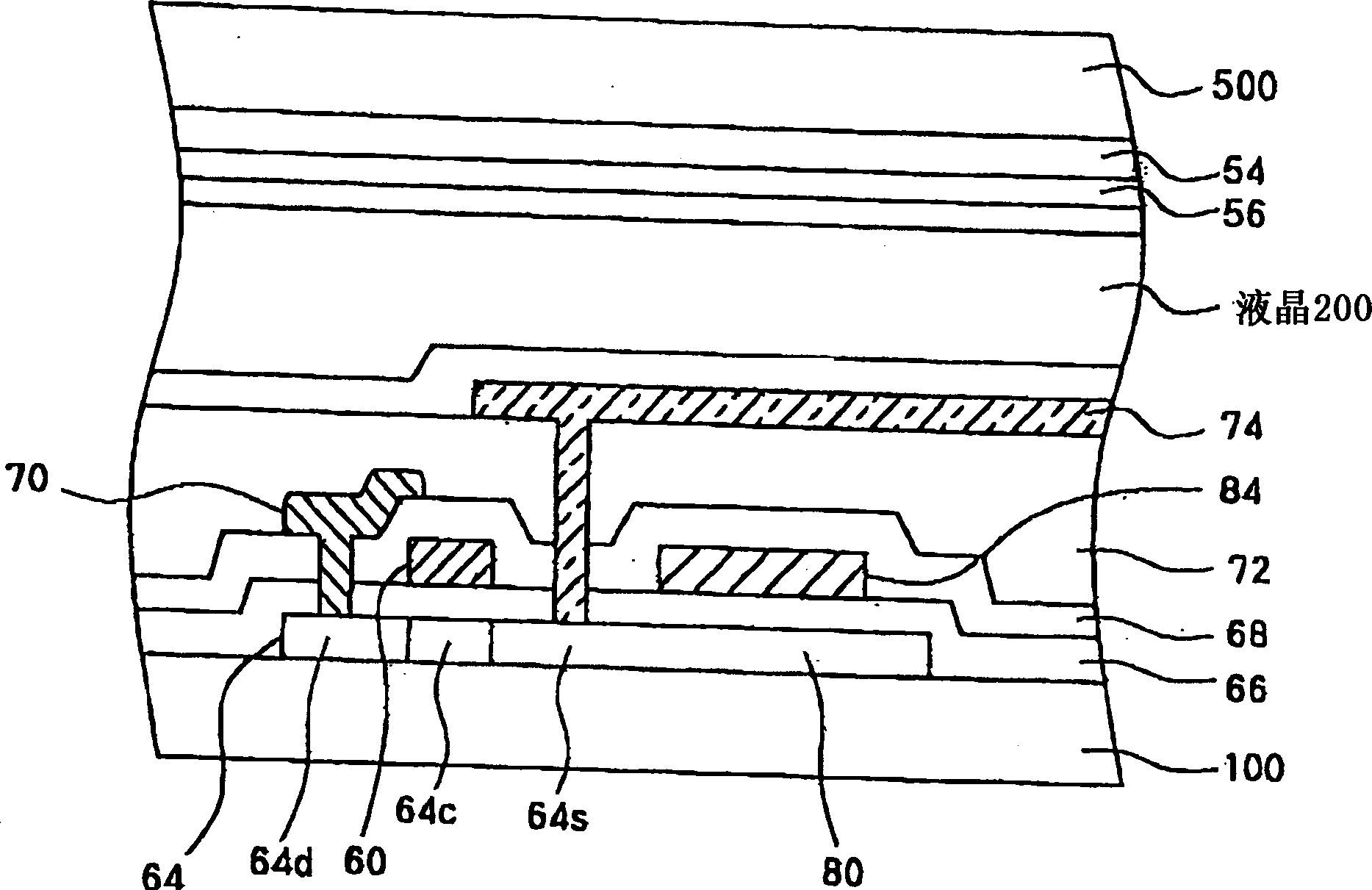

[0064] First, the pixel portion will be described. Figure 4 , Shows the planar structure of the pixel portion of the LCD related to the first embodiment, Figure 5 , Is the display edge Figure 4 The schematic cross-sectional structure of the LCD at the A-A line position, Figure 6 , Is the display edge Figure 4 The cross-sectional structure on the first substrate at the position of the B-B line.

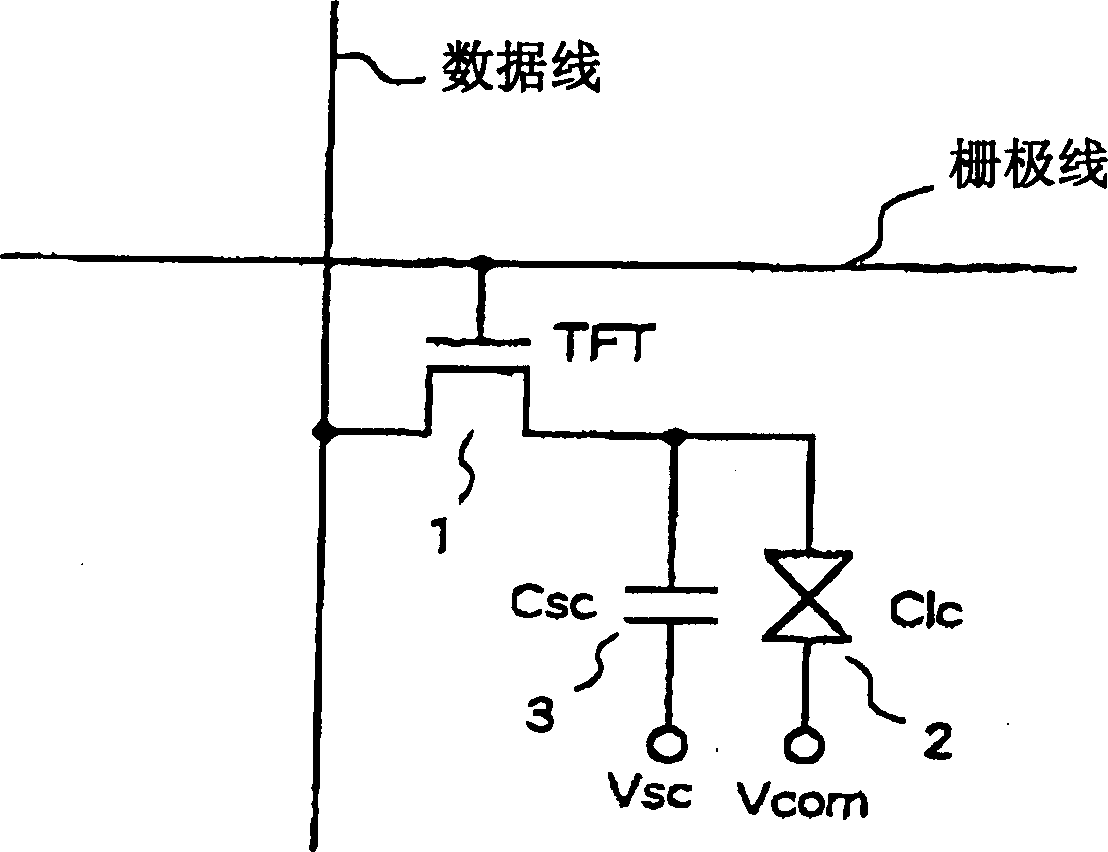

[0065] The equivalent circuit of each pixel is the same as that of FIG. 1, on the first substrate 100, such as Figure 4 As shown, the pixel electrodes 24 are arranged in a matrix, corresponding to each pixel electrode 24, and are provided with a top gate type TFT1 and an auxiliary capacitor 3 (Csc). In each pixel, the active la...

no. 2 Embodiment

[0100] Picture 12 , Is a plane structure for displaying display pixels of the dynamic matrix LCD related to the second embodiment. And along this Picture 12 The schematic cross-sectional structure of the LCD at the position of the A-A line is the same as the above Figure 5 the same. Figure 13 , Is the display edge Picture 12 The cross-sectional structure on the first substrate at the B-B line position. In addition, the same symbols are attached to the structures corresponding to the drawings described below, and the description is omitted.

[0101] The auxiliary capacitor Csc is the first electrode 30 and the second electrode 32, sandwiching the insulating layer 12 to form an overlapping area. Although this point is the same as the above embodiment, in the second embodiment, the first electrode 30 and the TFT The active layer 14 is integrally formed, and in order to make the first electrode 30, the active layer 14 can be formed along the data line 22 passing through the edge...

no. 3 Embodiment

[0112] Figure 14 , A schematic planar structure in each display pixel of the dynamic matrix liquid crystal display device related to the third embodiment. However, for the pixel electrode 24, the description is omitted for easy viewing of the drawing. In addition, Figure 15 , Is the display edge Figure 14 The cross-sectional structure on the first substrate at the position of the C-C line. Common symbols are attached to the parts that are common to the above-mentioned first and second embodiments.

[0113] In the second embodiment described above, in order to prevent coupling, the layout is performed so that the first electrode of the auxiliary capacitor integrated with the TFT active layer does not overlap the data line 22. In contrast, in the third embodiment, the first electrode 30 of the auxiliary capacitor overlaps the data line formation area, and in order to prevent coupling, in the overlap area with the first electrode 30 and the data line, A conductive sealing layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com