Plate-type middle-temp solid oxide fuel battery stack module

A technology of solid oxide and fuel cell stacks, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell groups, etc., can solve the problems of reducing manufacturing costs and achieve the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

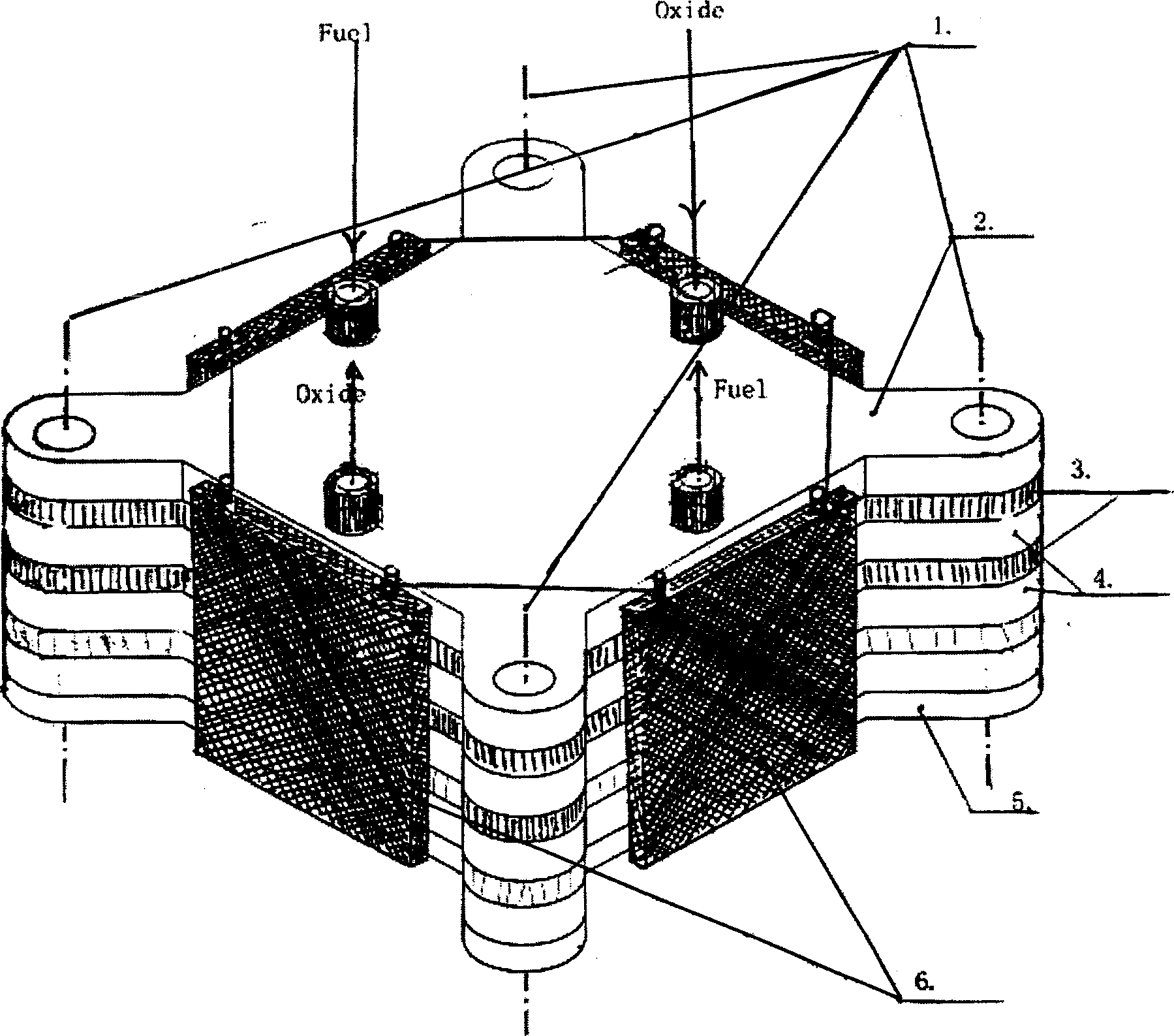

[0016] like figure 2 As shown, n=2, the upper cover 2, the single battery sheet 3, the connection plate 4 and the bottom plate 5 are all quadrilaterals, and their stacked arrangement is the same as that of the prior art, and their four corners protrude to form a fixing hole 1, and the fixing hole 1 Install bolts in the middle to secure, forming a fixed area. The surface formed by the edges of the upper cover 2, the single cell sheet 3, the connection plate 4 and the bottom plate 5, and the upper and lower sides of the upper cover and the bottom plate are equipped with six heating and heat preservation sheets 6 (the upper and lower two sheets are not shown in the figure), Together they form the working area of SOFC. For the battery stack, the temperature in the fixed area is lower than that in the working area, which is lower than the temperature at which the bolts undergo high-temperature creep, so that the compression and sealing can be naturally achieved through thermal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com