Static force loading measuring and controlling equipment for material microstructure tester and its method

A microstructure, static load technology, applied in the direction of measuring devices, analyzing materials, using optical devices, etc., can solve the problems of fine observation and precise measurement, difficulty, poor observation effect, etc., to achieve high-precision adjustment, convenient and fast The effect of convenient positioning and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the implementation of the present invention is described in detail as follows:

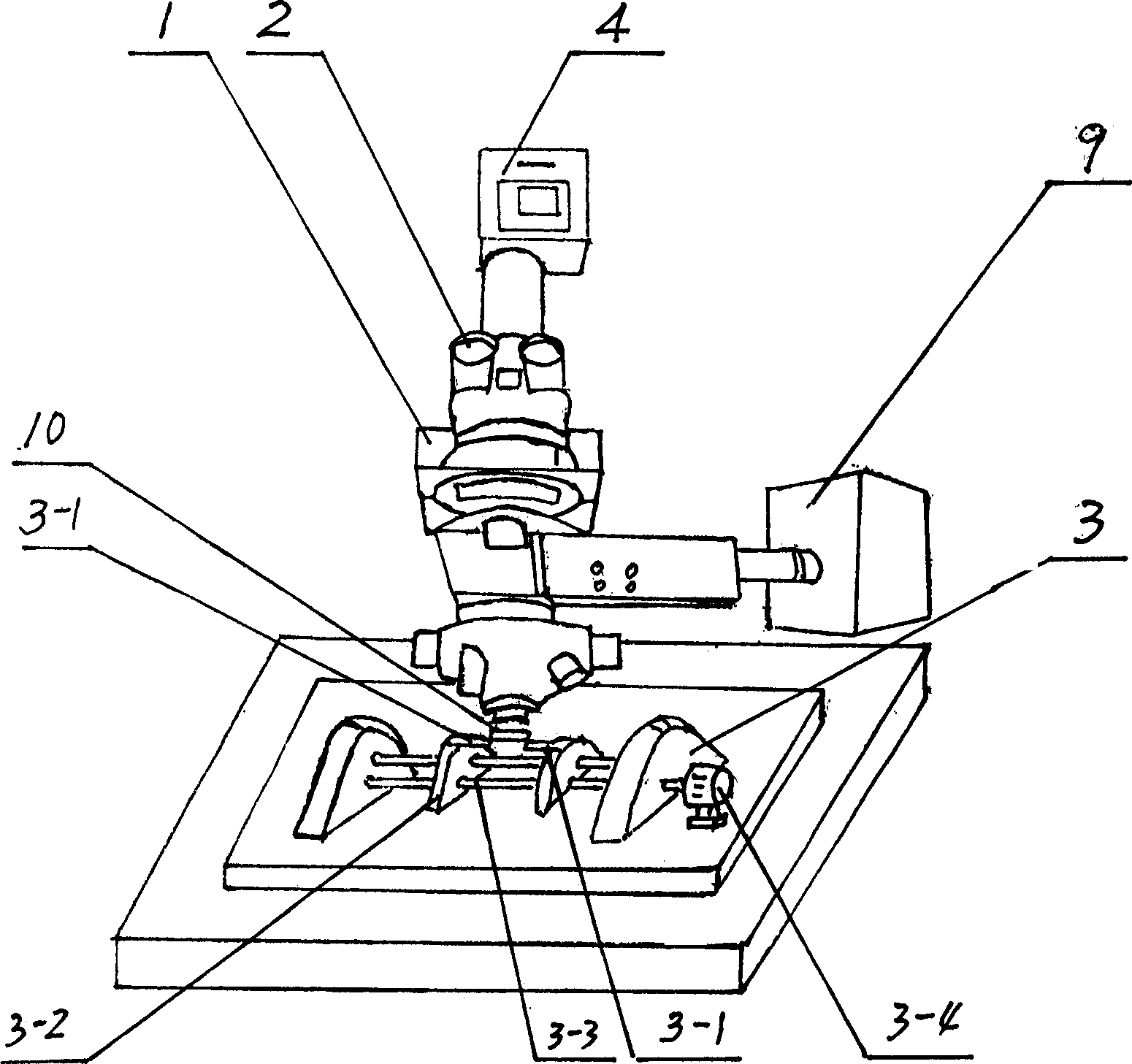

[0025] exist figure 1 Among them, a static loading device 3 is provided on the stage of the microscope 1 . The microscope 1 can adopt microscopic objective lenses with different magnifications, such as: OLYMPUS industrial microscope, the minimum magnification is 50 times, the maximum magnification is 2000 times, and it is equipped with a long focal length objective lens. The microscope 1 can also adopt a polarizing microscope, and its magnification can be selected according to the different microstructures of the test pieces. The microscope 1 is provided with a light source device 9, which has wires connected to the power supply 6 for observing and measuring the light source. There is a space of 160-200mm between the stage of the microscope 1 and the microscope objective lens, which is used to place large materials, components, and loading e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com