Hollow section sliding sash with disappearing screen window

A technology of invisible screens and profiles, applied in the direction of insect prevention, etc., can solve the problems of increasing mold costs, aggravating negative impacts, and complicated production processes, and achieves the effects of increasing the welding surface area, improving welding strength, and flexible and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

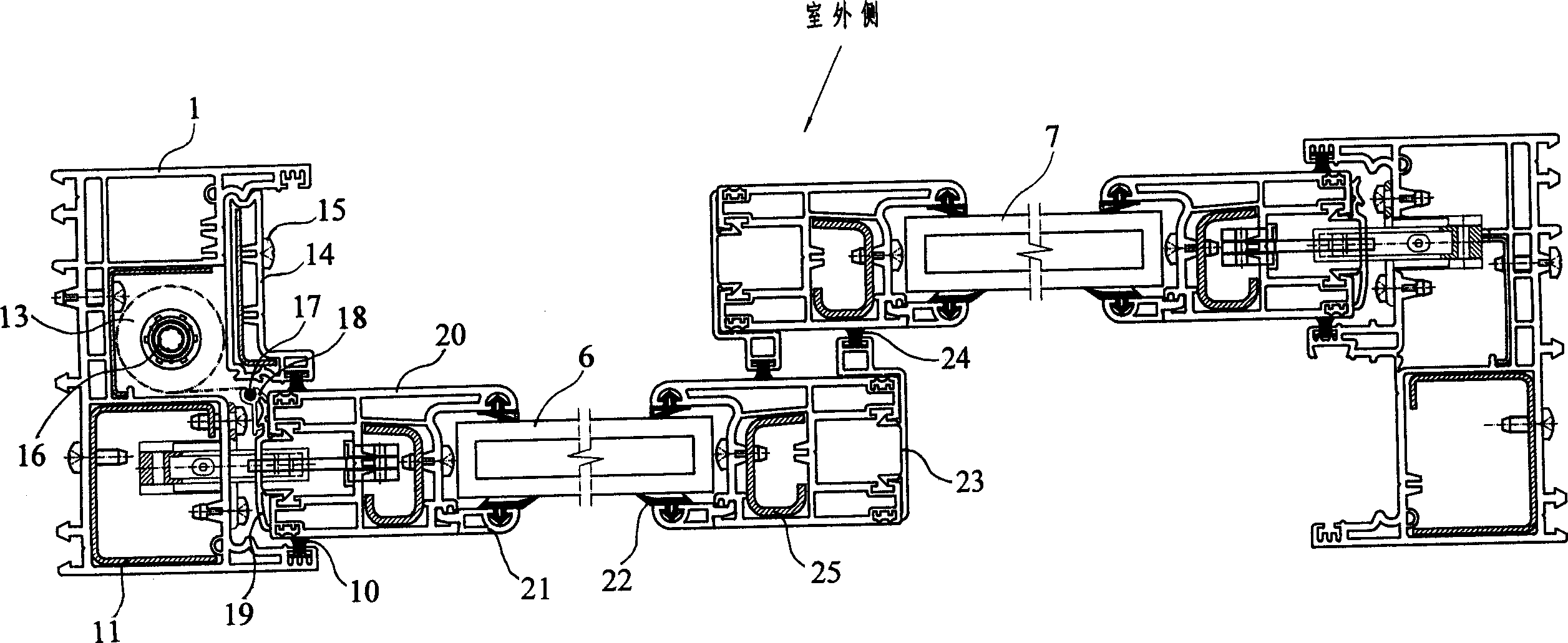

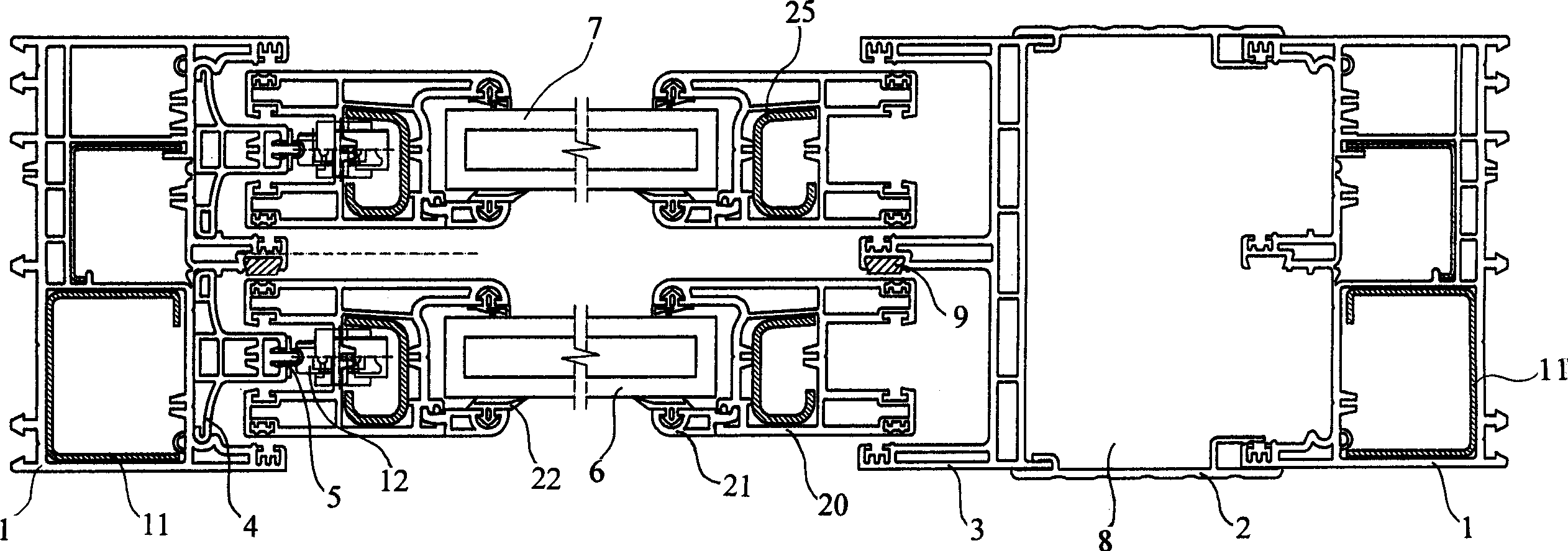

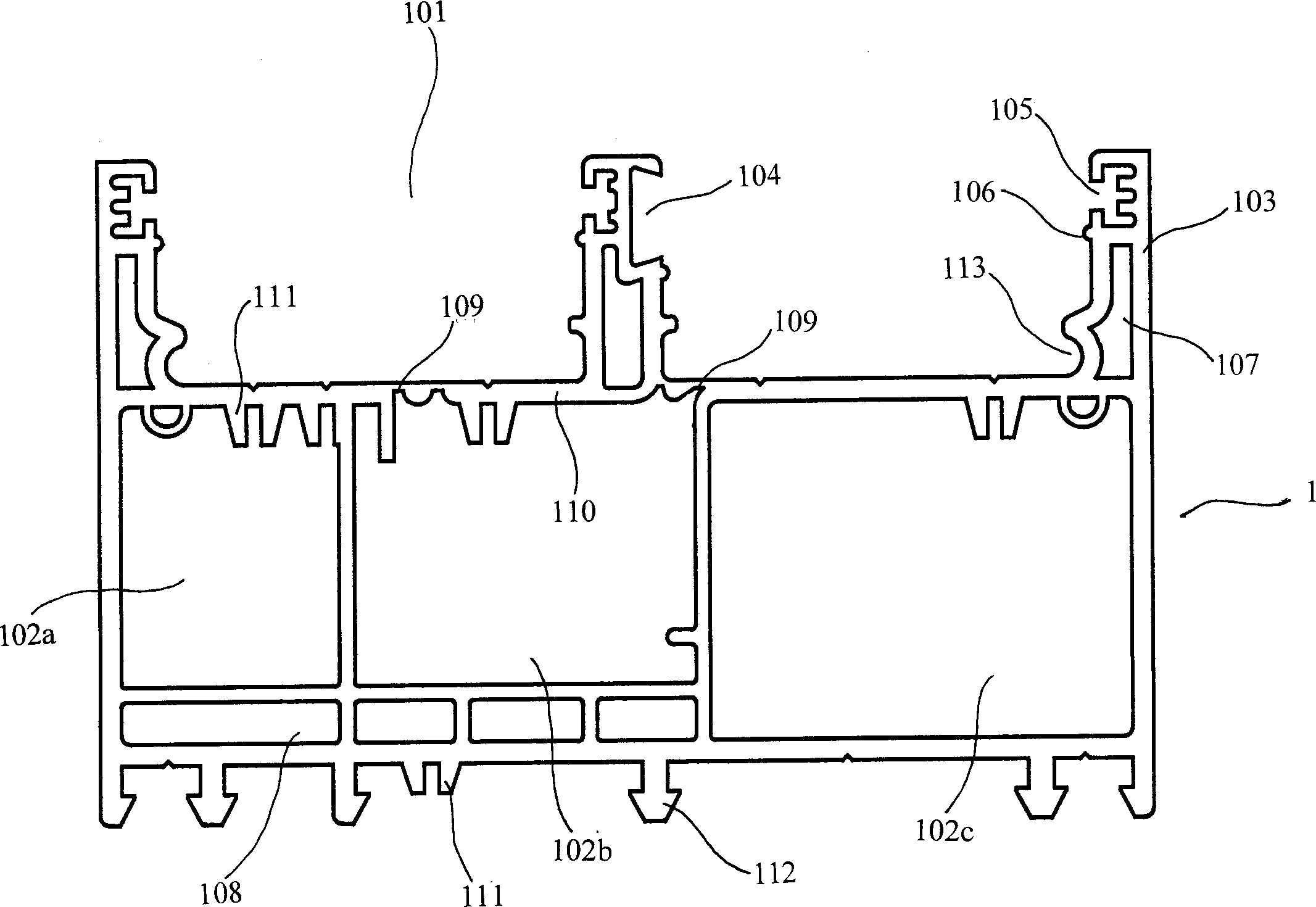

[0026] The hollow profile window with invisible screen window described in this embodiment, such as figure 2 As shown, it has a top-down containment by the standard box (upper)1 (cf. image 3 ), chassis panel 2 (see Figure 9 ), middle frame 3 (see Figure 10 ) constitutes the upper window frame, and the standard frame (lower) 1 and the track frame 4 embedded in it from bottom to top (see Figure 8 ) and the lower window frame formed by the guide rail 5. A framed glass sash 6 and a glass sash 7 are embedded between the upper sash and the lower sash (see Figure 4 ). The above-mentioned upper window frame and lower window frame are horizontally arranged window frames fixedly connected with the wall. The chassis panel 2 between the above-mentioned three parts of the upper window frame is respectively stuck in the frame wall of the standard fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com