Surface discharge type plasma display screen with dual discharge spaces

A technology of discharge space and plasma, applied in static indicators, cold cathode tubes, instruments, etc., can solve the problems that non-discharge gaps cannot be guaranteed, phosphors are not fully utilized, and PDP life is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

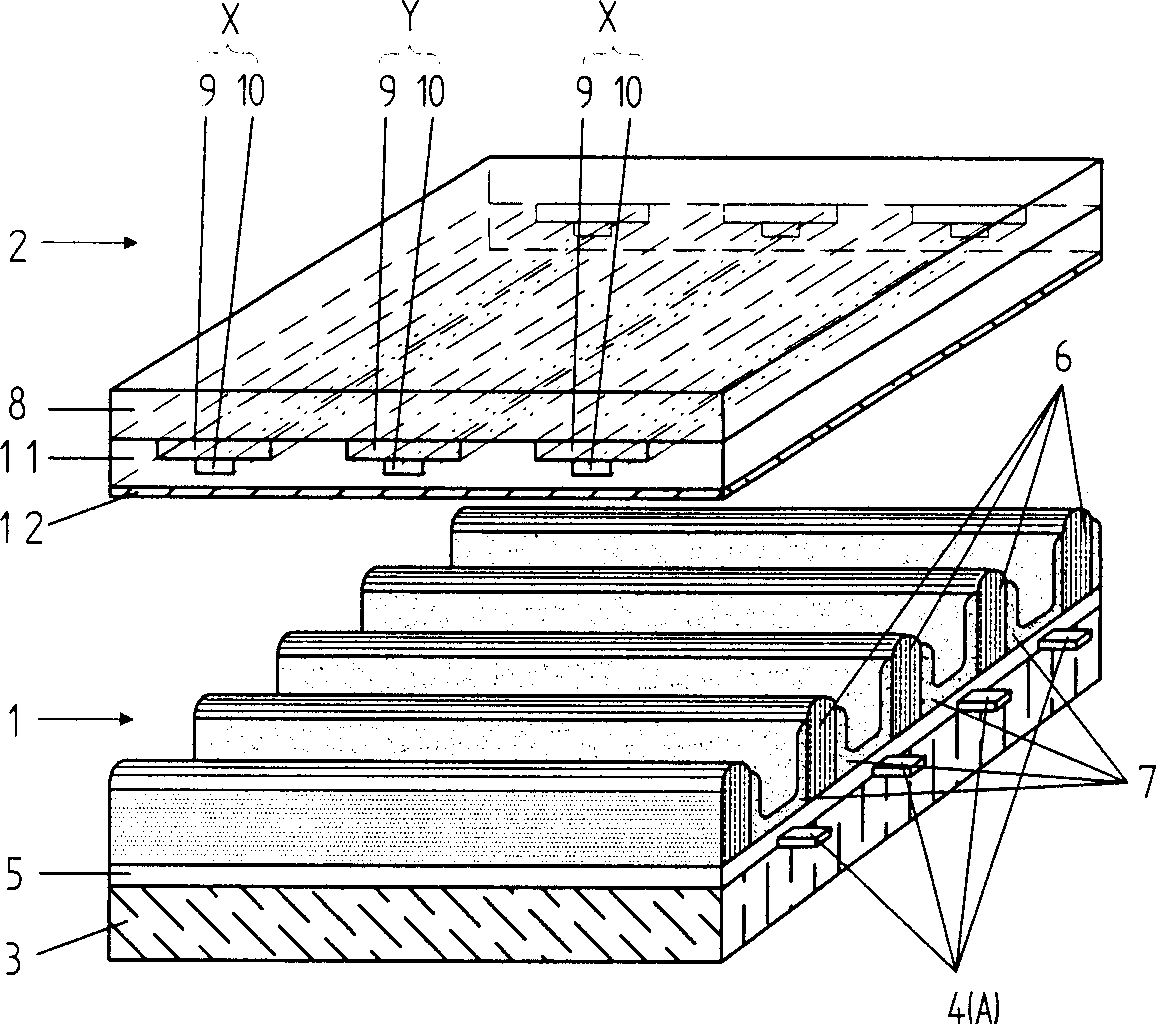

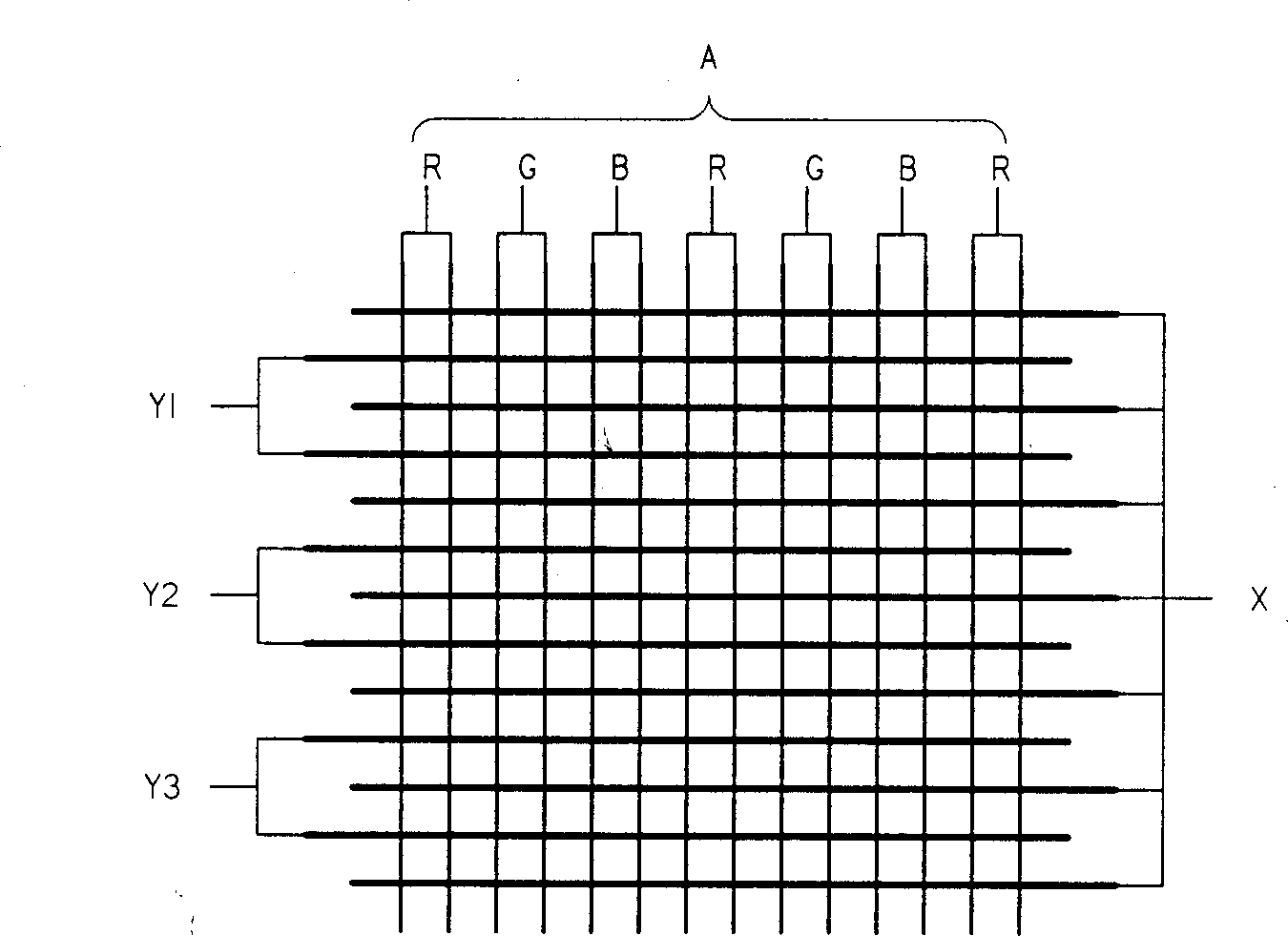

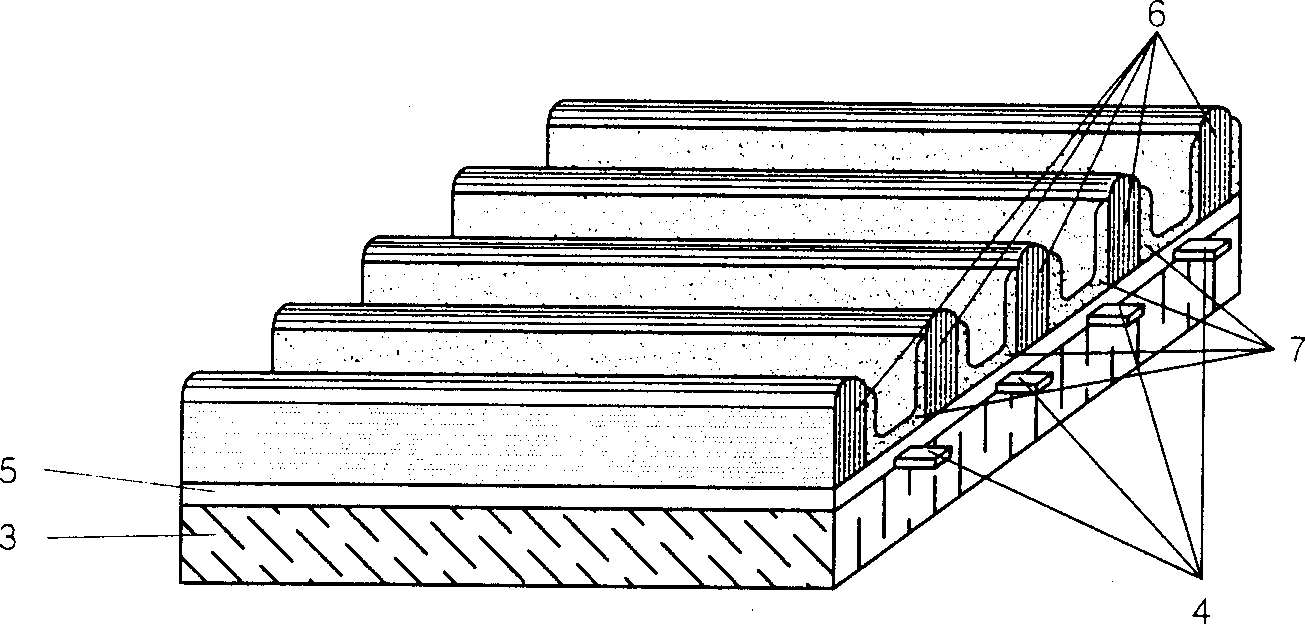

[0047] Please refer to figure 1 , Figure 5 and Image 6 As shown, the plasma display screen of the present invention includes a lower substrate 1, an upper substrate 2 and a control and driving circuit. Wherein: the lower substrate 1 is composed of a lower substrate glass 3, a metal electrode 4 formed on the lower substrate glass 3, a dielectric layer 5 formed on the metal electrode 4, and a dielectric layer 5 formed on the dielectric layer 5 to prevent optical crosstalk The barrier ribs 6 and the red, green and blue photophosphor 7 formed between the barrier ribs 6 are formed. The upper substrate 2 includes an upper substrate glass 8 , transparent electrodes 9 formed on the lower surface of the upper substrate glass 8 at equal intervals, a metal bus electrode 10 formed at the center of the lower surface of the transparent electrode 9 , and the metal bus electrode 10 consists of a dielectric layer 11 and a protective film 12 formed on the lower surface. The address electr...

no. 4 example

[0051] image 3 As shown, in the first embodiment, a fourth embodiment of the present invention is constituted by coating all monochromatic photo-phosphor powders between the barriers to realize monochromatic display. Fifth embodiment:

[0052] Figure 4 As shown, in the first embodiment, the barrier is not coated with fluorescent powder but only filled with discharge gas, and the color of the gas discharge is used to realize monochrome display, which constitutes the fifth embodiment of the present invention. Sixth embodiment:

[0053] Figure 7 , Figure 8 As shown, in the above-mentioned first to fifth embodiments, the scan electrodes and the sustain electrodes are made of unequal widths, including the unequal widths of the transparent electrodes and the unequal widths of the metal bus electrodes, but the width of the transparent electrodes on the scan electrodes All are the same, the widths of the metal bus electrodes are all the same, the widths of the transparent ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap