Fuel reforming system

A reforming system and fuel reformer technology, applied in fuel cells, fuel cell additives, inorganic chemistry, etc., can solve problems such as inability to install evaporators, space limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

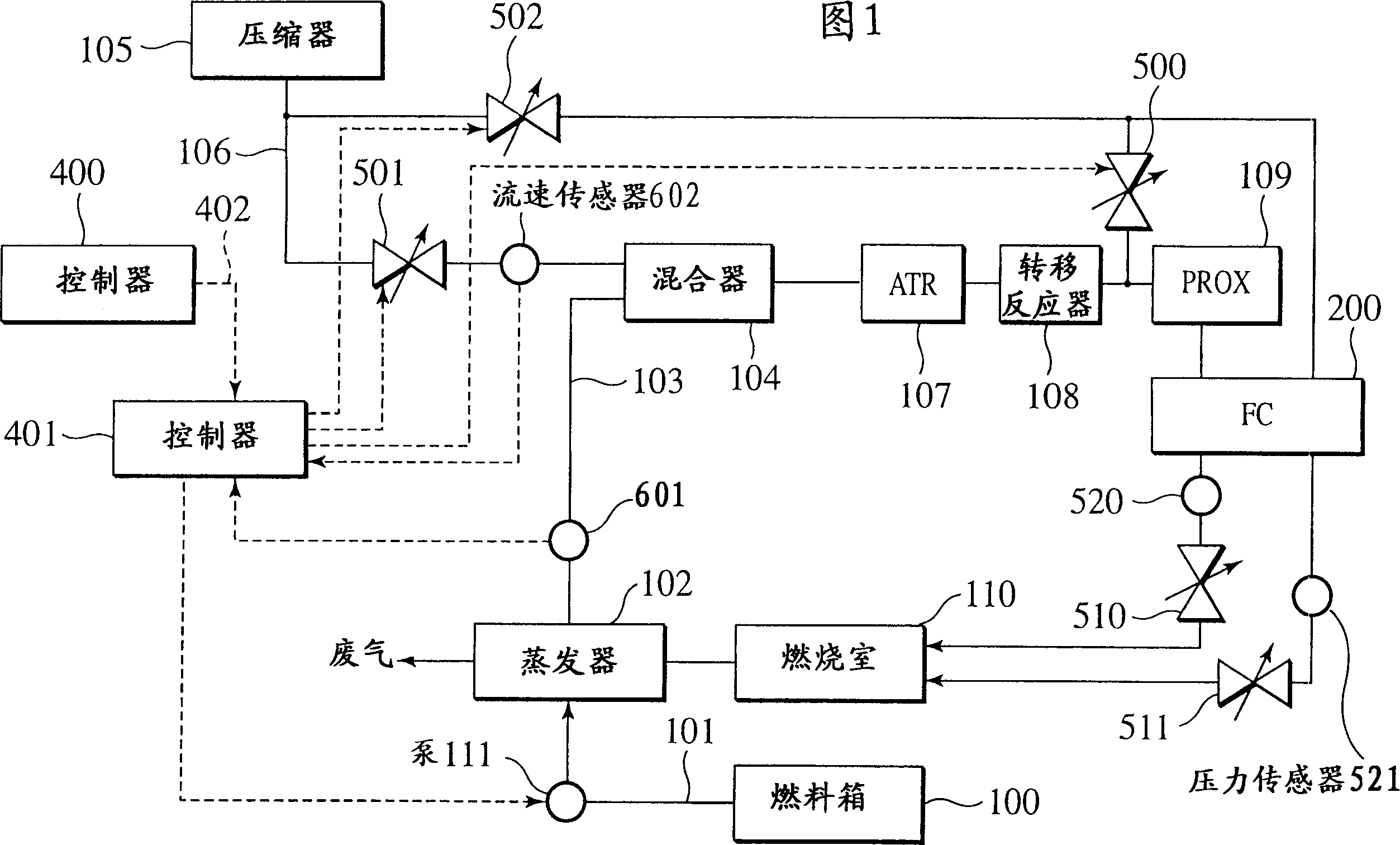

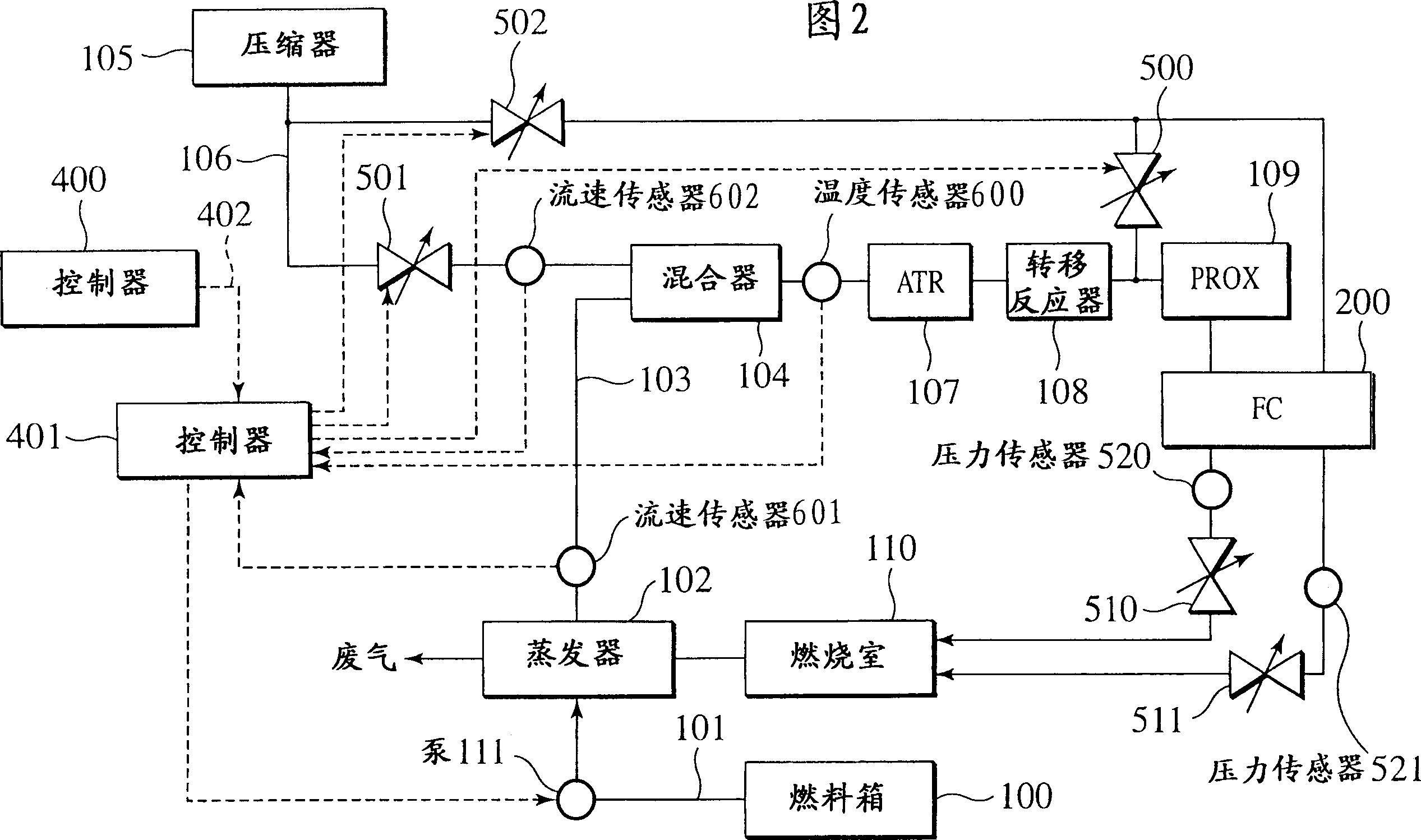

[0043] The fuel reforming system in the first embodiment will be described with reference to FIGS. 2 to 7 . The fuel reforming system of the first embodiment shown in FIG. 2 is characterized in that a temperature sensor 600 is introduced to detect the temperature of the mixture to be sent to an autothermal reforming reactor 107, and the output of the temperature sensor 600 is transmitted to the fuel reforming reactor 107. whole controller 401. In FIG. 2 , the same reference numerals are used for the same components as those of the prior art shown in FIG. 1 .

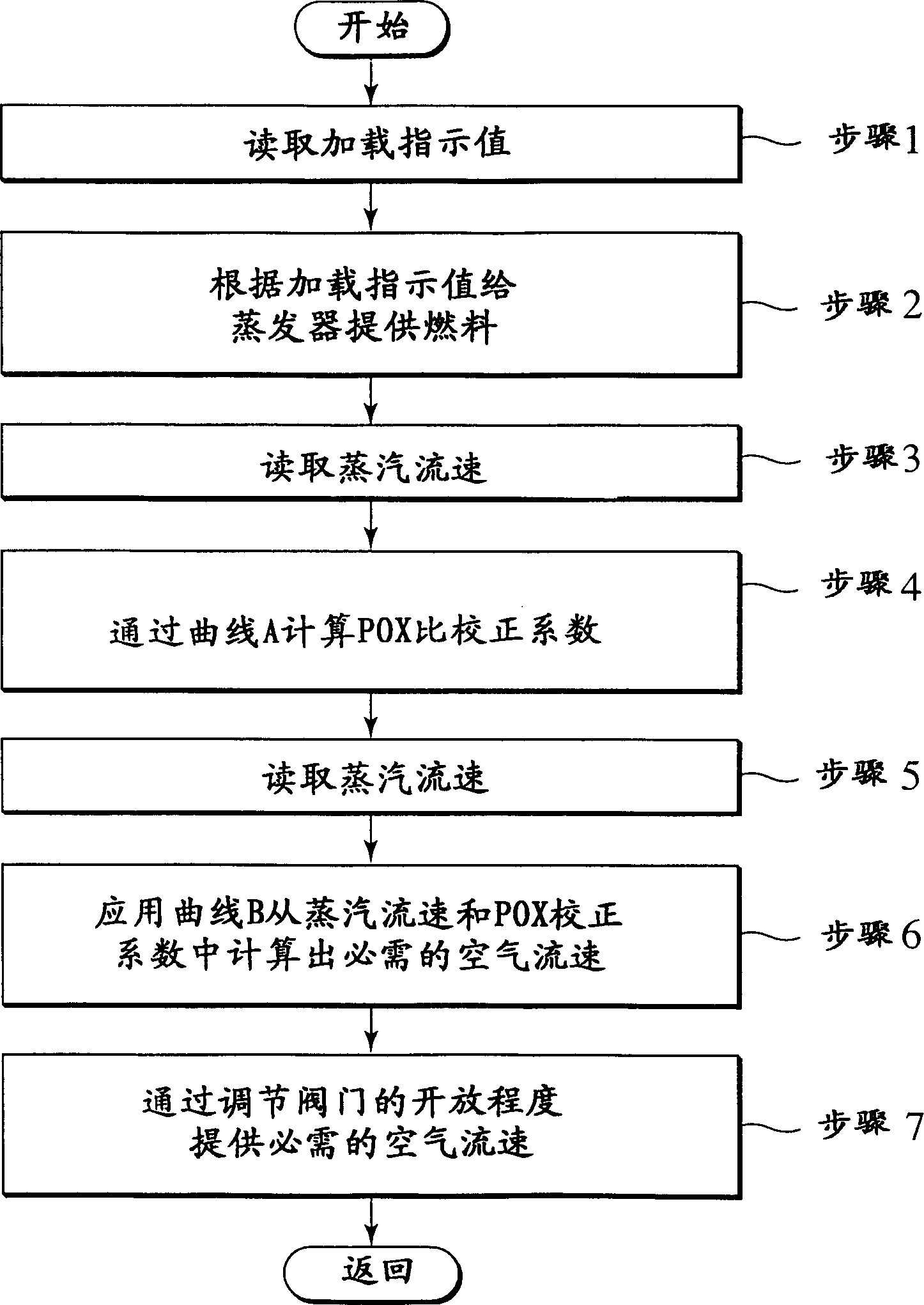

[0044] The control sequence of the fuel reforming controller 401 of the fuel reforming system refers to image 3 Be explained.

[0045] Step 1: The fuel reforming controller 401 reads a work load signal 402 of the fuel reforming system transmitted from the controller 400;

[0046] Step 2: the fuel reforming controller 401 controls the pump 111 according to the duty loading signal 402, and provides a necessary flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com