Full-fiber nanometer-precision microdisplacement and microvibration interference measuring instrument

An interferometric measurement and micro-displacement technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as poor anti-interference ability, difficult adjustment, wavelength drift, etc., to reduce adjustment difficulty, save modulation light source, and eliminate light stress. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

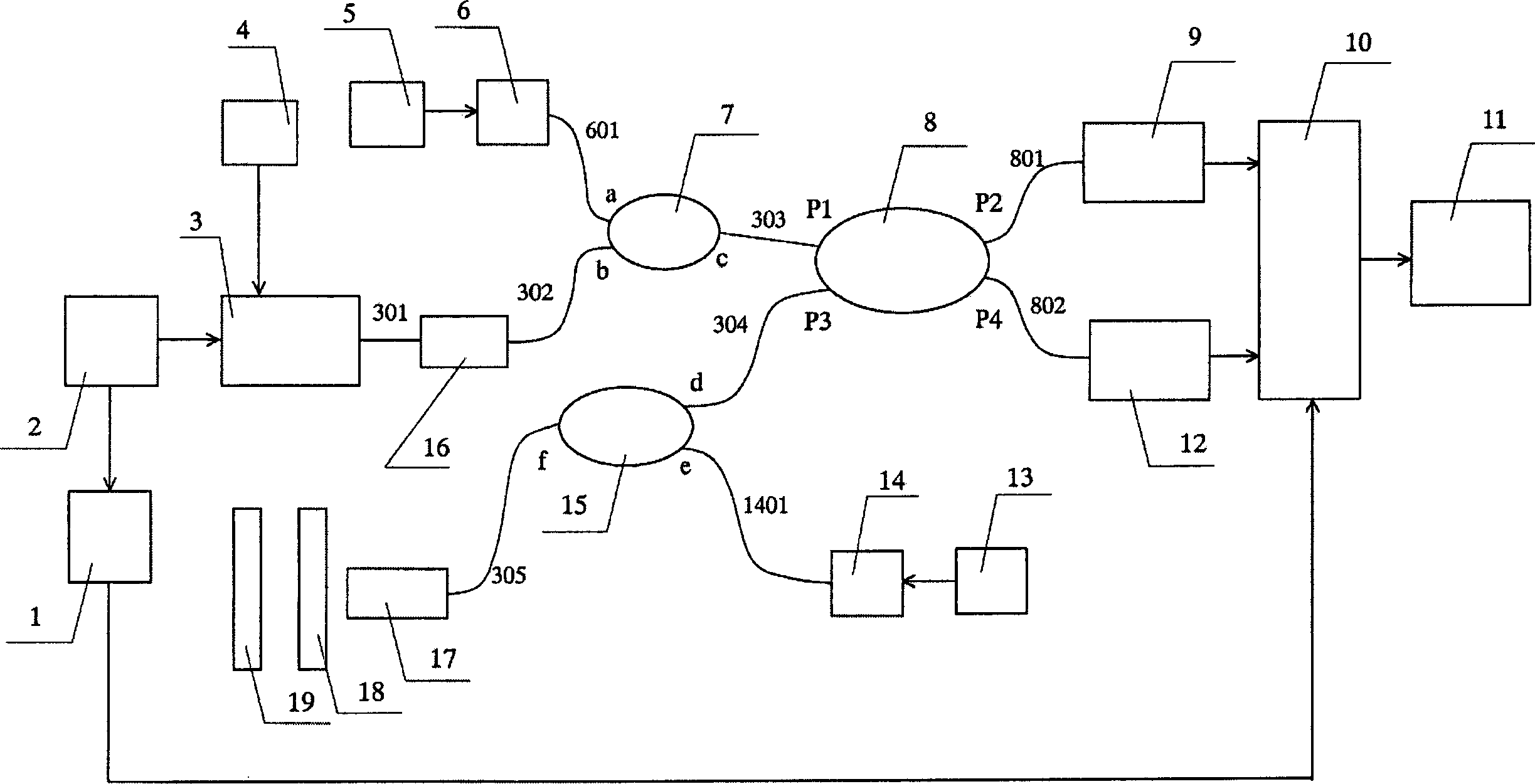

[0036] Such as figure 1 structure shown. The collimated light source 6 is a semiconductor laser with a wavelength of 660nm and a maximum output power of 30mW. The excitation light source 14 is a semiconductor laser with a wavelength of 785nm and a maximum output power of 50mW. The light source 3 adopts a distributed feedback semiconductor laser (DFB-LD) with a wavelength of 1305 nm. The first photoelectric conversion element 9 and the second photoelectric conversion element 12 are photodiodes, and their wavelength response is in the 1.3 μm band. The first multiplexer element 7, the second multiplexer element 15 and the coupler 8 are all fiber couplers. The splitting ratio of the coupler 8 is 1:1. The diameter of the outgoing beam of the collimator 17 is 0.2 mm. The reflectivity of the partially reflective element 18 is 27%. When starting the measurement, the light source 3 is first turned on, and the temperature of the light source 3 is stabilized by the temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com