Water strainer without power source

A decanter and power technology, which is applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of large power consumption and complex structure of the decanter, and achieve low cost and simple equipment. , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

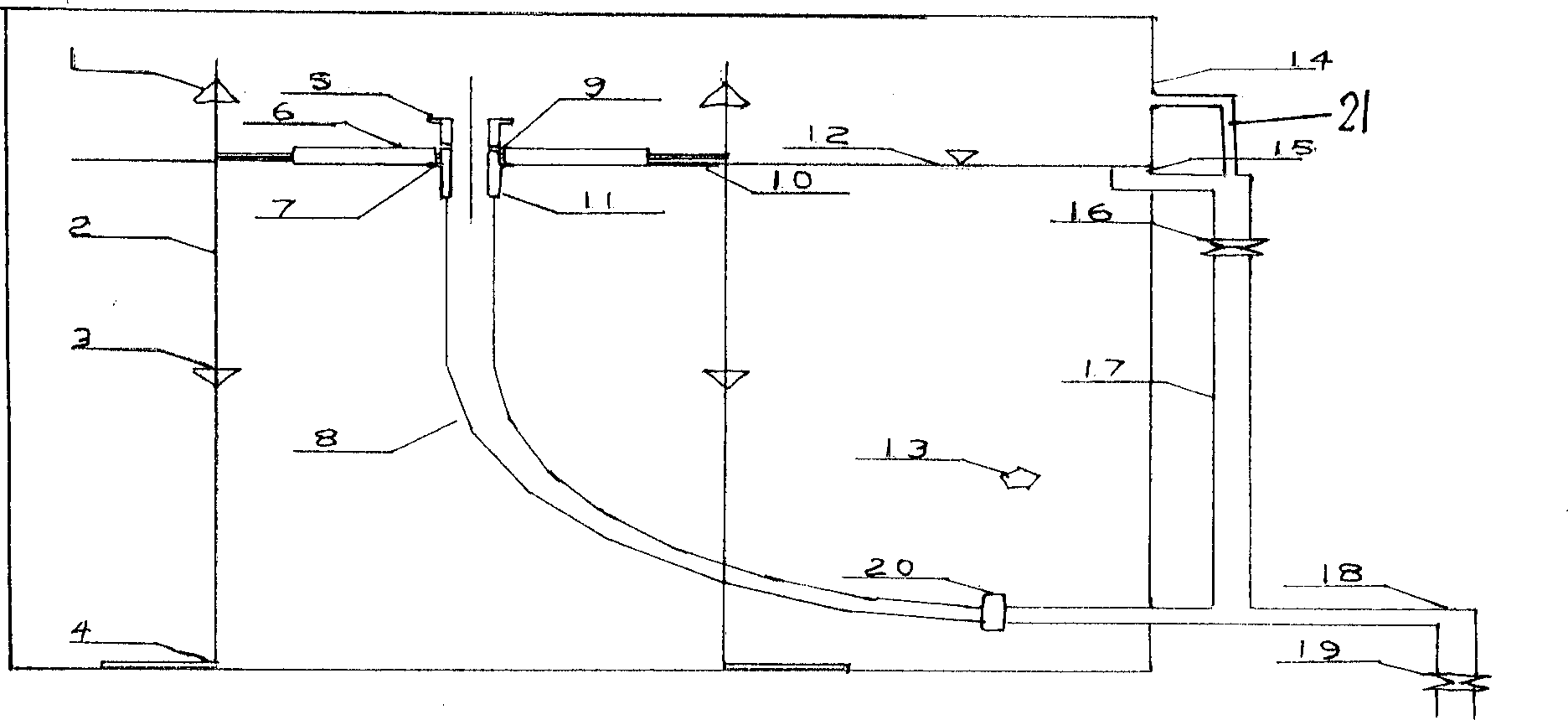

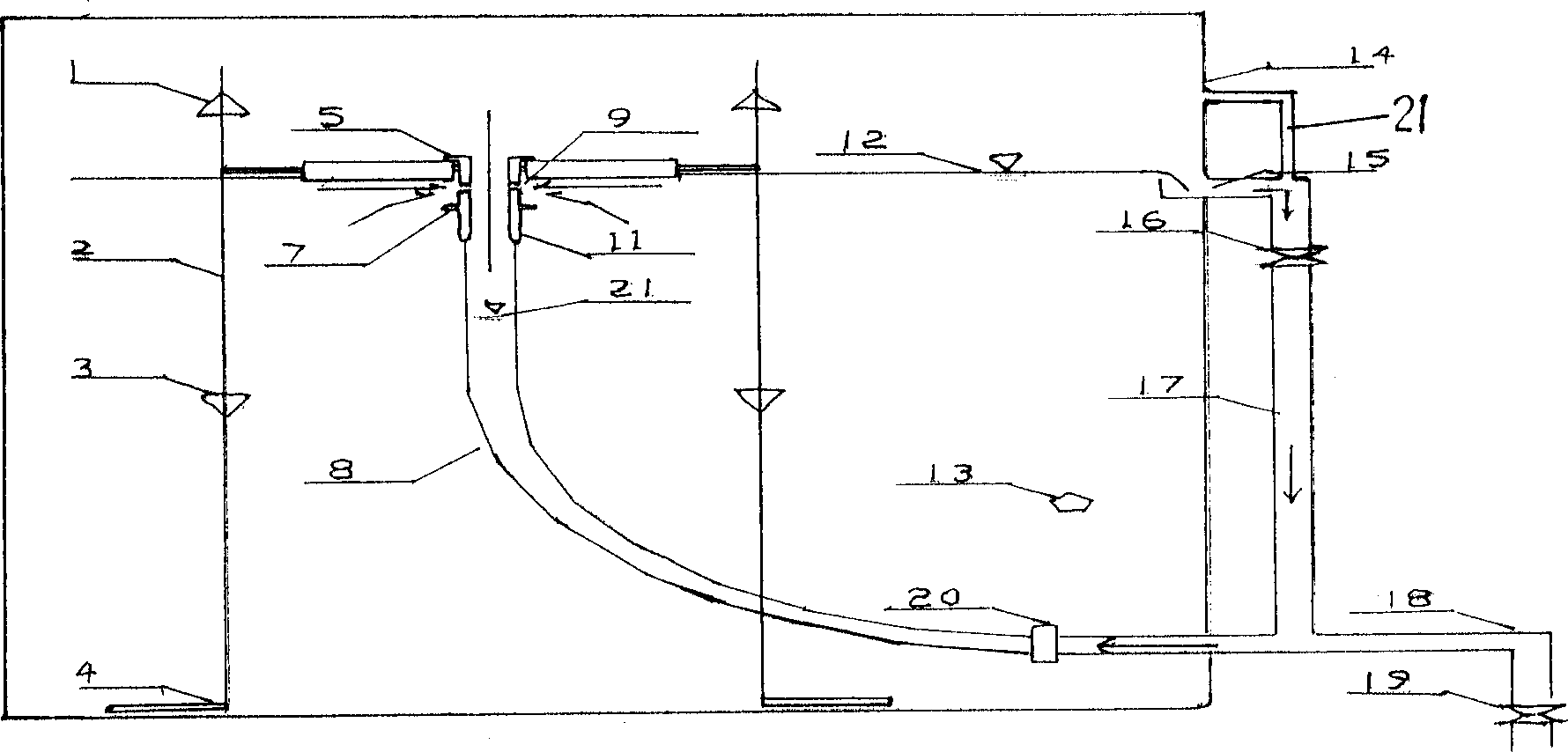

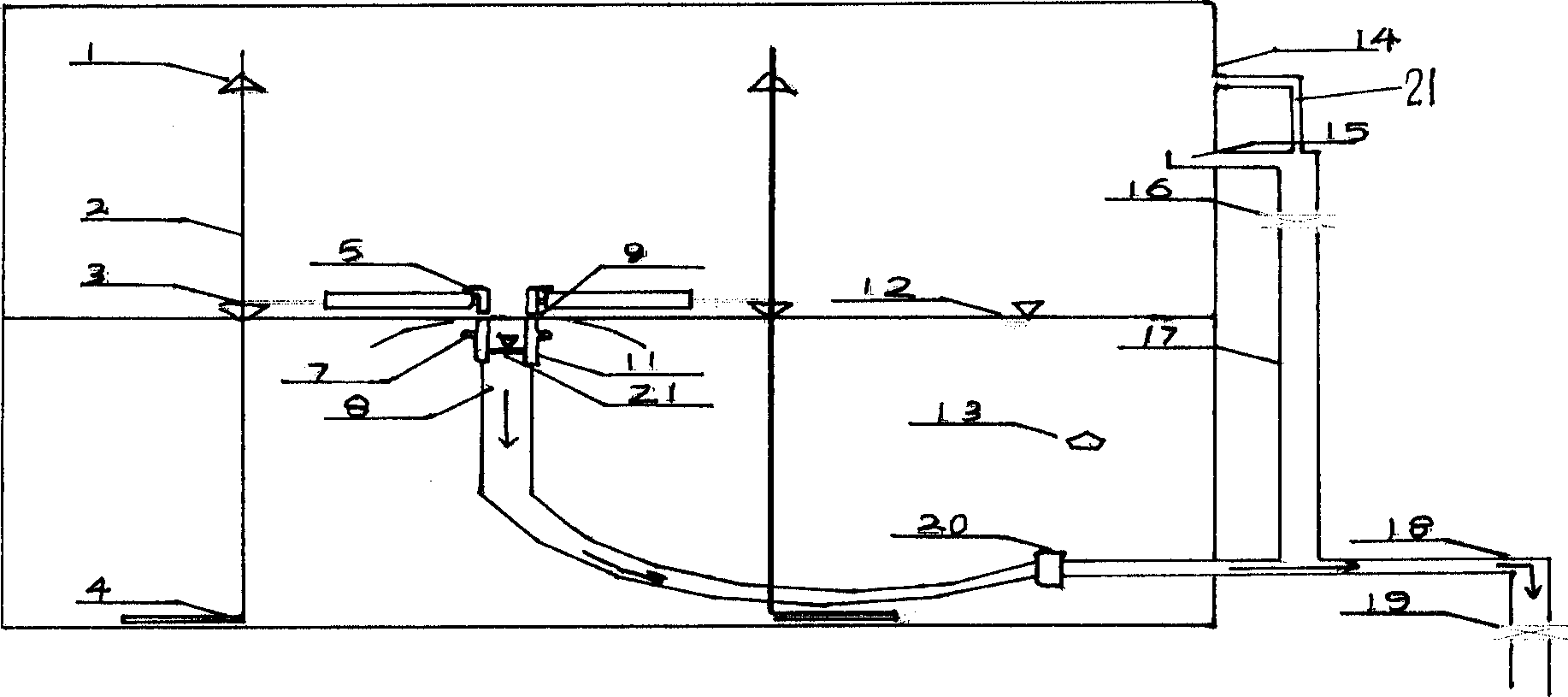

[0026] The non-powered decanter of the present invention has a water collection device on the liquid surface 12, and the water collection device has a float 6 that can float up and down along the vertical guide rail 2. The vertical guide rail is provided with a float upper limit 1 and a float lower limit 3 , The float is connected to the drain pipe 8, the upper part of the drain pipe is connected to the rigid straight pipe 11, the middle part of the rigid straight pipe has a drain port 9, the upper and lower limit devices 5 and the lower limit device 7 are arranged on the upper and lower drain ports, and the drain pipe 8 drains from the bottom of the container through the interface 20 The main pipe 18 is connected, and the main drainage pipe leads to the outside of the container. It is connected to the communication groove 15 on the upper part of the container by the connecting water injection pipe 17. There is an exhaust pipe 21 on the connecting water injection pipe directly lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com