Grid assembly for rotary dust-collecting device of vacuum dust collector

A dust collection device and dust collector technology, which is applied in the direction of swirl devices, devices whose axial direction of swirl can be reversed, vacuum cleaners, etc., can solve the problem of reduced dust collection capacity of vacuum dust collectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

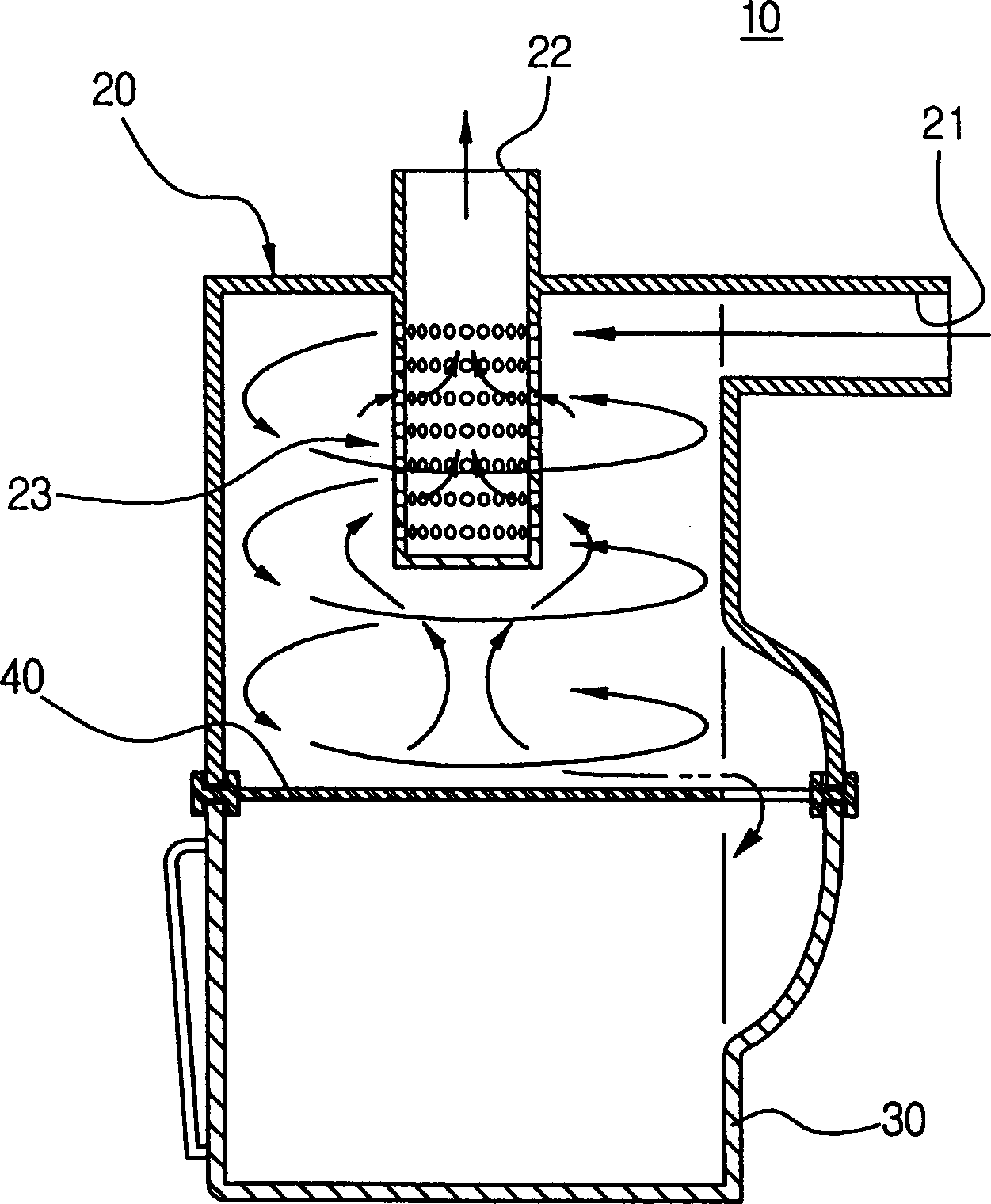

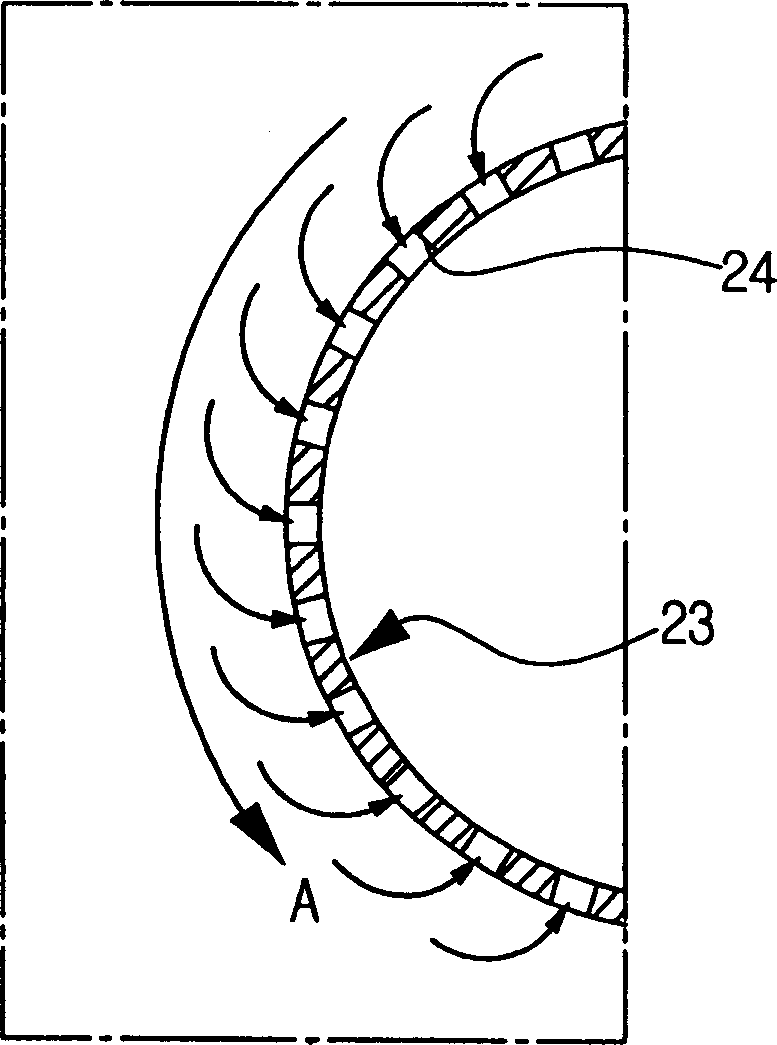

[0020] Now, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

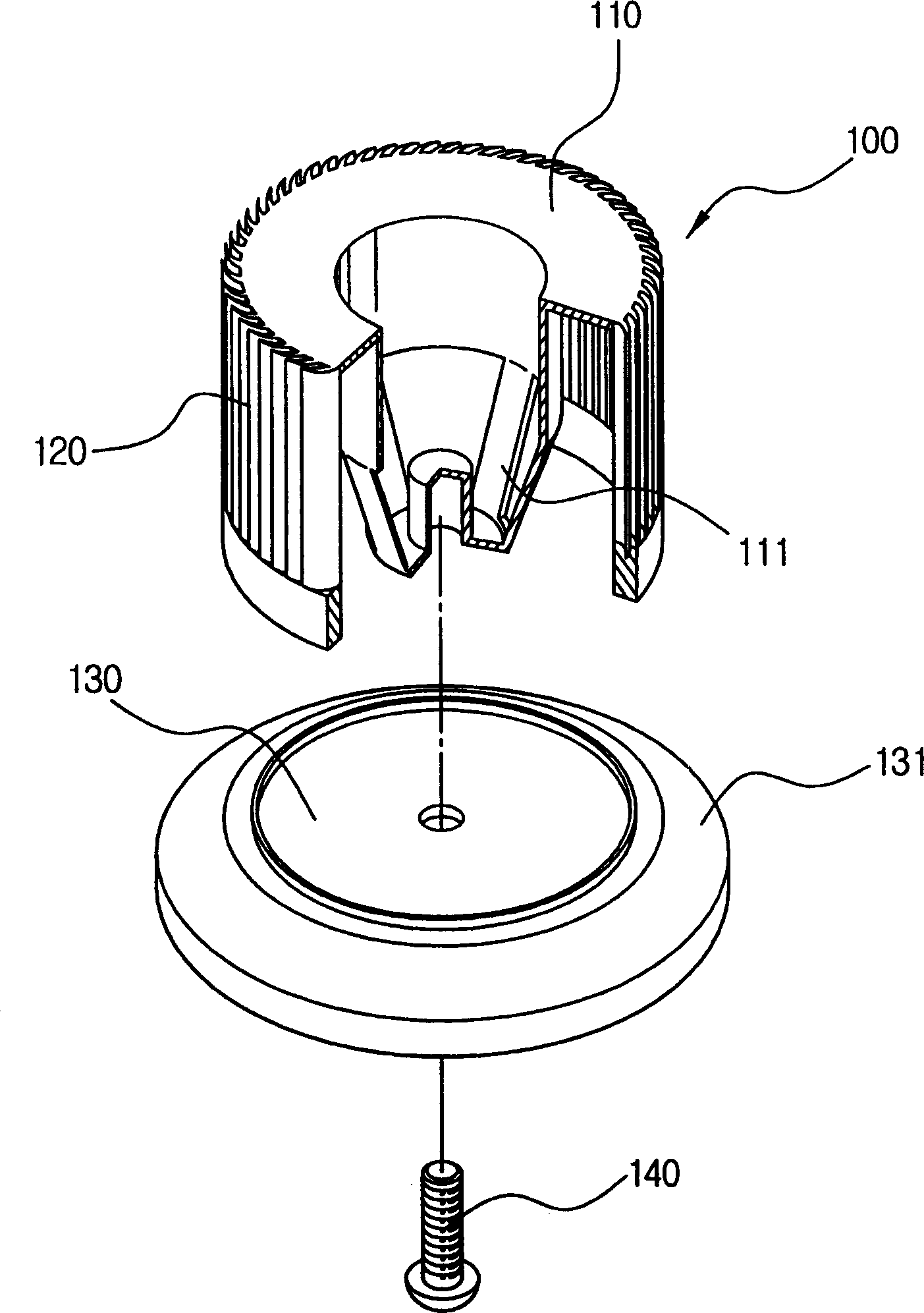

[0021] image 3 An example of a mesh assembly of a rotary dust collector of a vacuum cleaner in the present invention is shown. The grid assembly 100 for a rotary dust collecting device of a vacuum cleaner includes: a grid body 110 , a plurality of blades 120 and a protection member 130 .

[0022] like Figure 4 As shown, the cylindrical mesh body 110 has openings at its upper and lower ends, the upper opening is connected with the exhaust channel 220 of the cyclone body 200 , and the lower opening is blocked by the protective piece 130 .

[0023] The protection member 130 is connected with the bracket 111 formed integrally with the grid main body 110 through screws 140 . In other words, the protector 130 can be separated from the grid main body 110 by turning the screw 140, and thus, the grid assembly 100 can be easily repaired and maintained.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com