Wire electric discharge machining device

A processing device and electric discharge wire technology, applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve problems such as easy slack, broken wires, and processing accuracy are not considered, and achieve the effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

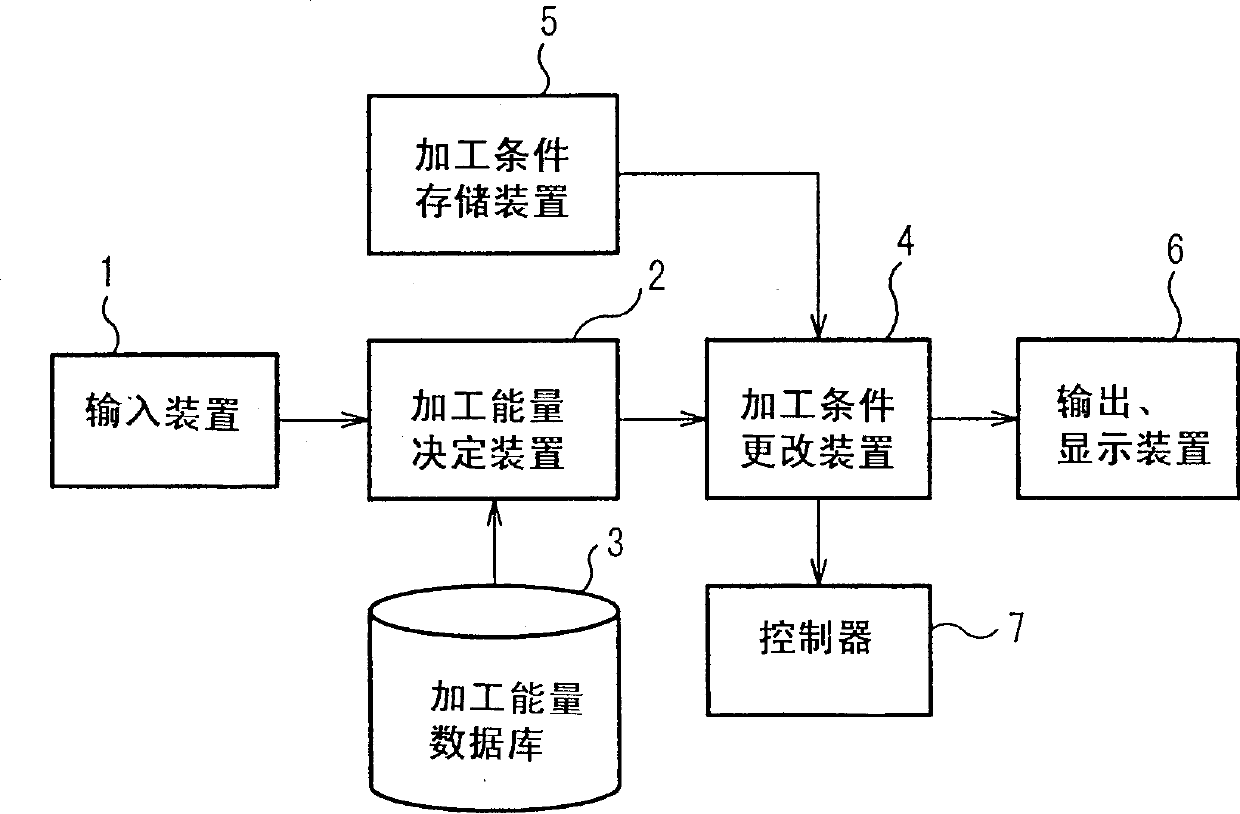

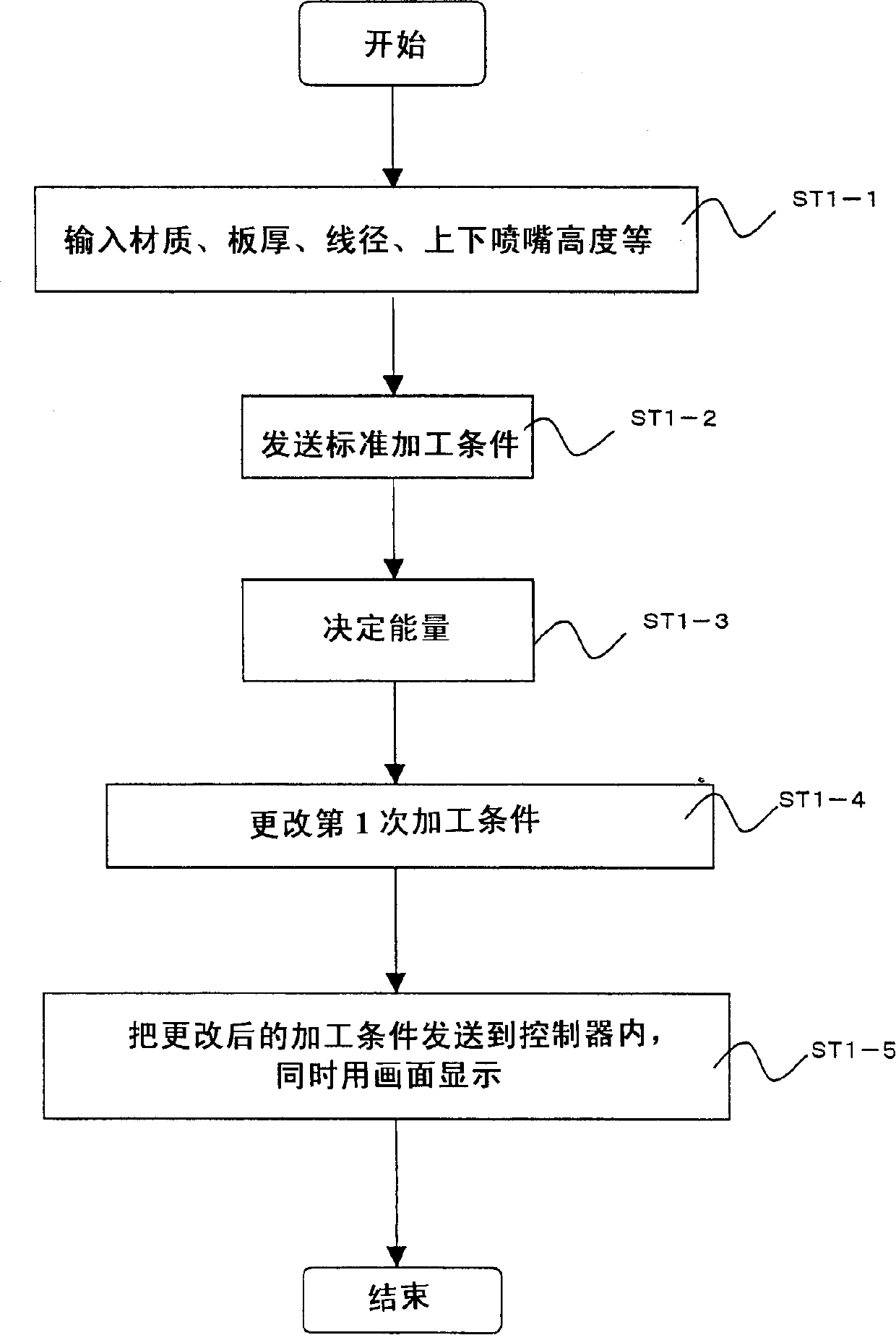

[0033] Fig. 1 is a structural diagram showing Embodiment 1 of the present invention. In the figure, 1 is an input device, usually a keyboard. 2 is a processing energy determining device, and 3 is a processing energy database. In this database, as shown in FIG. Described above in proportion to standard processing conditions. Here, the nozzle height indicates, for example, a state where the nozzle 70 is separated from the workpiece 72 as shown in FIG. 10A . This ratio data only refers to the first processing. The processing energy determination device 2 determines the processing energy according to the plate thickness read from the processing energy database 3, the relevant data of the height of the upper nozzle and the height of the lower nozzle. In the processing energy determining device 2 , the determined processing energy data is sent to the processing condition changing device 4 . 5 is a processing condition storage device, which stores charging voltage, conduction tim...

Embodiment 2

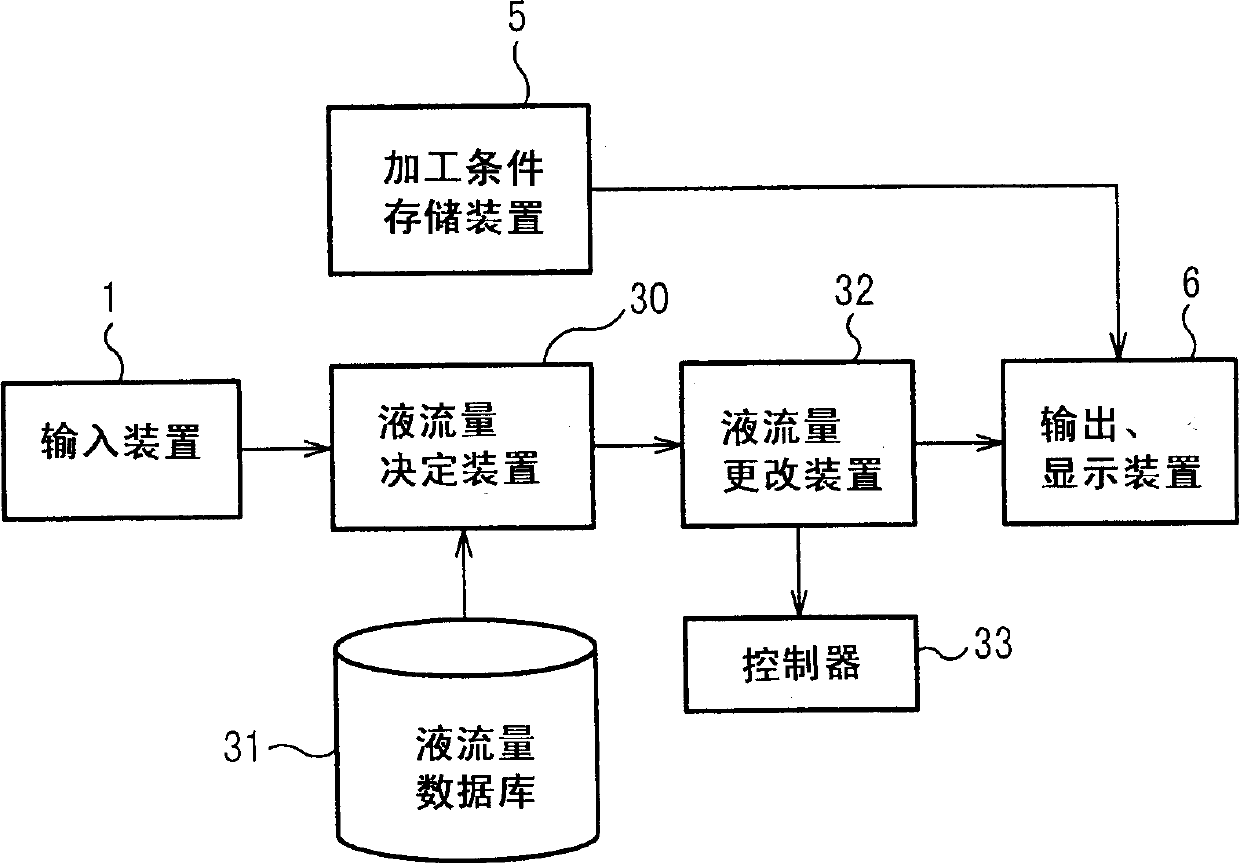

[0043] Fig. 4 is a configuration diagram showing Embodiment 2 of the present invention, and Fig. 5 is a flow chart showing the operation of Embodiment 2 of the present invention. Among the figure, 1 is the input device identical with embodiment 1, adopts keyboard usually. 30 is a liquid flow determining device related to the machining fluid flow (hereinafter referred to as liquid flow), and 31 is a liquid flow database. In this liquid flow database 31, as shown in FIG. Corresponding to the height of the nozzle, the liquid flow rate under the continuous line condition is described in proportion to the usual above-mentioned standard processing conditions. The data for this ratio only refer to the first processing. The liquid flow determining means 30 determines the liquid flow based on the data read from the liquid flow database 31 . The liquid flow data determined by the liquid flow determining device 30 is sent to the liquid flow changing device 32 . 5 is the same processin...

Embodiment 3

[0049] Fig. 7 is a configuration diagram showing the third embodiment of the present invention, and Fig. 9 is a flow chart showing the operation of the third embodiment of the present invention. Among the figure, 1 is an input device, and like embodiment 1, adopts keyboard usually. 50 is an inclination correction value determining device, and 51 is an inclination correction value database. As shown in FIG. The correction value of the line inclination of the whole process in the standard processing is described. In the inclination correction value determining means 50 , the line inclination correction value is determined based on the data read from the inclination correction value database 51 . The inclination correction value data determined by the inclination correction value determining device 50 is sent to the multi-process inclination correction value changing device 52 . 53 is a multi-process processing condition storage device, which stores charging voltage, conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com