Grain growth of electrical interconnection for microelectromechanical systems (MEMS)

A technology of micro-electromechanical systems and grain growth, applied in piezoelectric devices/electrostrictive devices, fluid pressure measurement using capacitance changes, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve welding defects, Leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

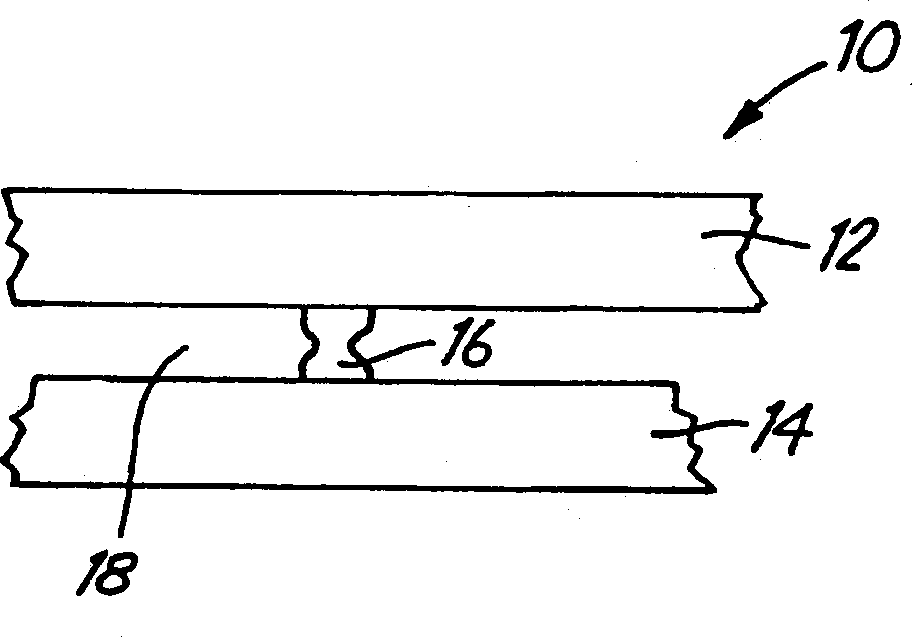

[0028] figure 1 is a simplified cross-sectional view of a portion of MEMS device 10 of the present invention. MEMS device 10 includes upper layer 12 and lower layer 14 . The layers 12 and 14 are electrically coupled together by the electrical connection 16 of the present invention. As explained in detail herein, electrical connection 16 is formed by a grain growth process to electrically couple said layers 12 and 14 together. Generally speaking, the invention can be used to provide a connection between two planar substrates, said connection extending in a vertical direction (ie the third dimension of the substrate). For example, electrical connection 16 may bridge gap 18 between two layers 12 and 14 . This technology can be used in various types of MEMS devices, such as pressure, acceleration, flow sensors, etc. Much of this specification that follows is specifically concerned with the use of, for example, figure 1 Connection 16 is shown for the pressure sensor. However,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com