Tea leaf tea-seed oil processing method

A processing method and technology of tea seed oil, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of waste of tea seeds, inability to remove saponin, affecting enthusiasm, etc., to prevent coronary heart disease, shorten processing cycle, improve Yield effect

Inactive Publication Date: 2010-11-10

李家福

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the processing of camellia oil, manual steps such as crushing, steaming, and stepping on cakes are required. The labor intensity is high, the efficiency is low, and the output is small.

Because the saponin in the raw material cannot be removed by the aforementioned traditional vegetable oil processing technology, only the seeds of non-bitter vegetable camellia can be used as oil plants, and the tea seeds containing saponin content are wasted

This has seriously affected the enthusiasm of tea farmers to grow tea

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A tea oil for preventing hypertension, hyperlipomia, coronary heart disease and habitual constipation is prepared from useless tea leaves and tea seeds through baking, squeezing to obtain raw oil and cake, refining the raw oil, immersion extracting of cake to obtain oil, and refining. Its advantages are simple process, low cost and high productivity.

Description

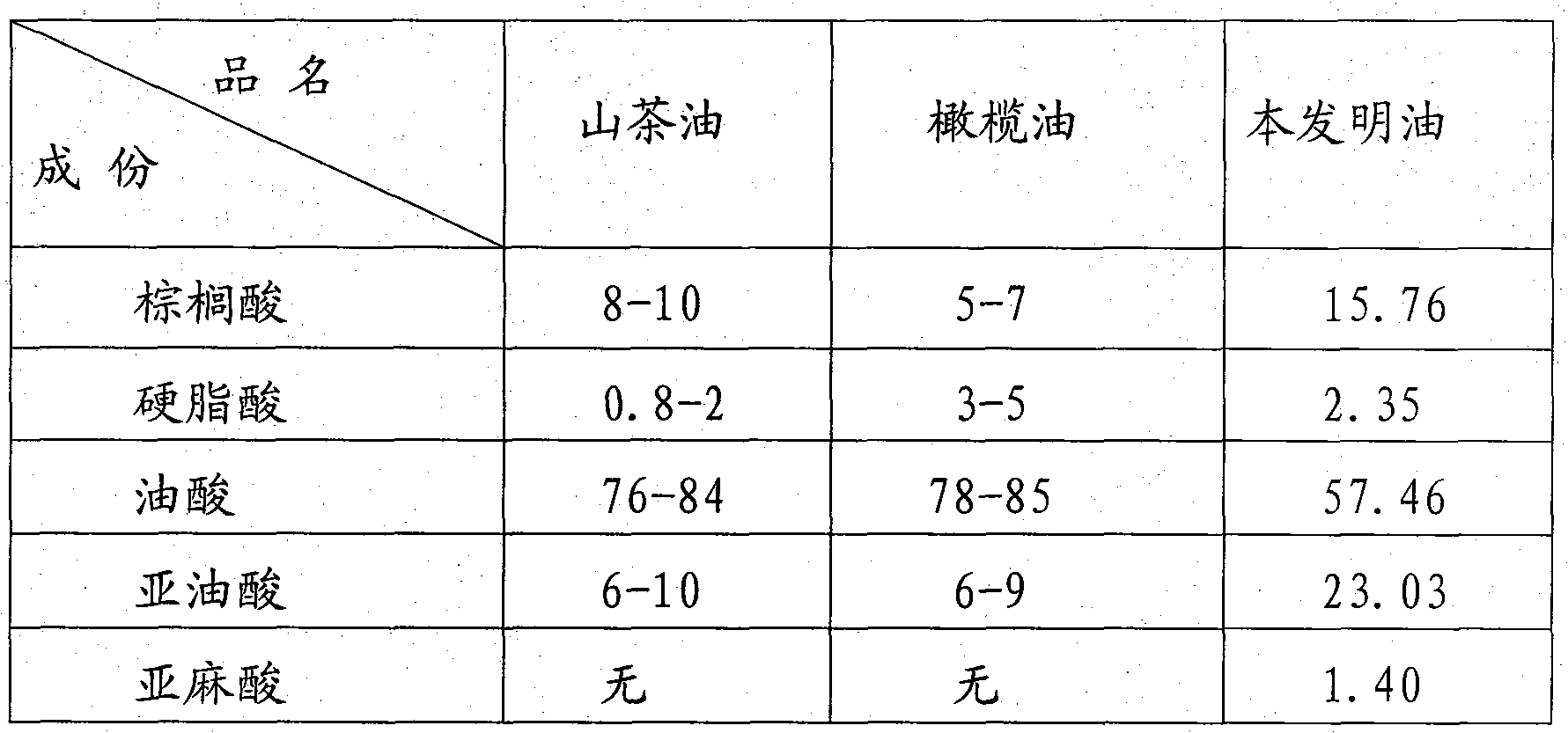

A kind of processing method of tea seed oil technical field The invention relates to an edible oil and a processing method thereof, in particular to tea and tea seed oil and a processing method thereof. Background technique At present, the vegetable oils that people consume more are camellia oil and olive oil. Camellia oil is made from the seeds of oil plant camellia oleifera, also known as camellia seeds, through drying (6-70% dry), crushing, steaming, cake pressing, refining and other processes of camellia seeds. During the processing of camellia oil, manual steps such as crushing, steaming, and cake stepping are required, which is labor-intensive, low-efficiency, and low-yield. Since the saponin in the raw material cannot be removed by adopting the aforementioned traditional vegetable oil processing technology, the seeds of vegetable camellia oleifera without bitterness can only be selected as the oil plant, and the tea leaves containing saponin content are wasted. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C11B1/06

Inventor 李家福

Owner 李家福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com