Manufacture of environment protecting snack box

A manufacturing method and technology for fast food boxes, applied in the directions of trays, flexible coverings, packaging, etc., can solve the problems of white pollution, waste of wood, social and environmental hazards, etc., and achieve high environmental protection value, simple structure, and improved overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

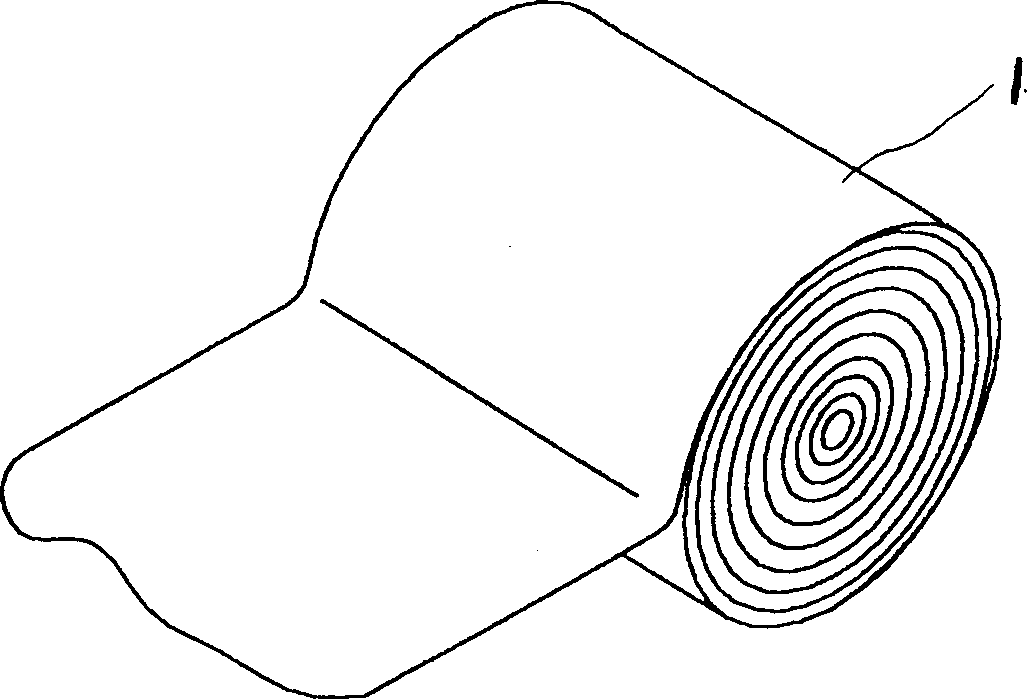

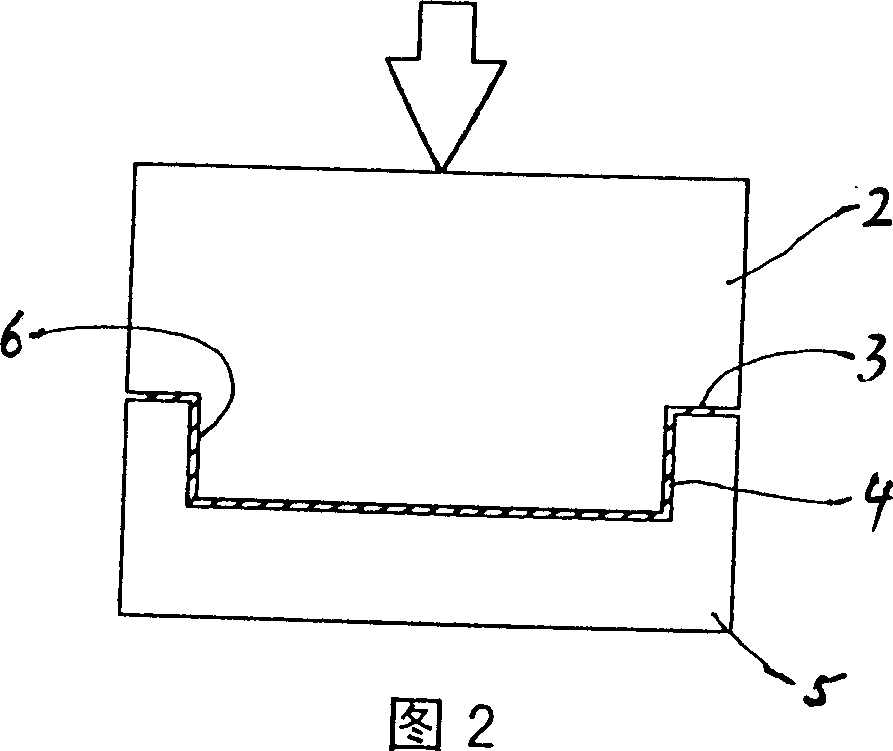

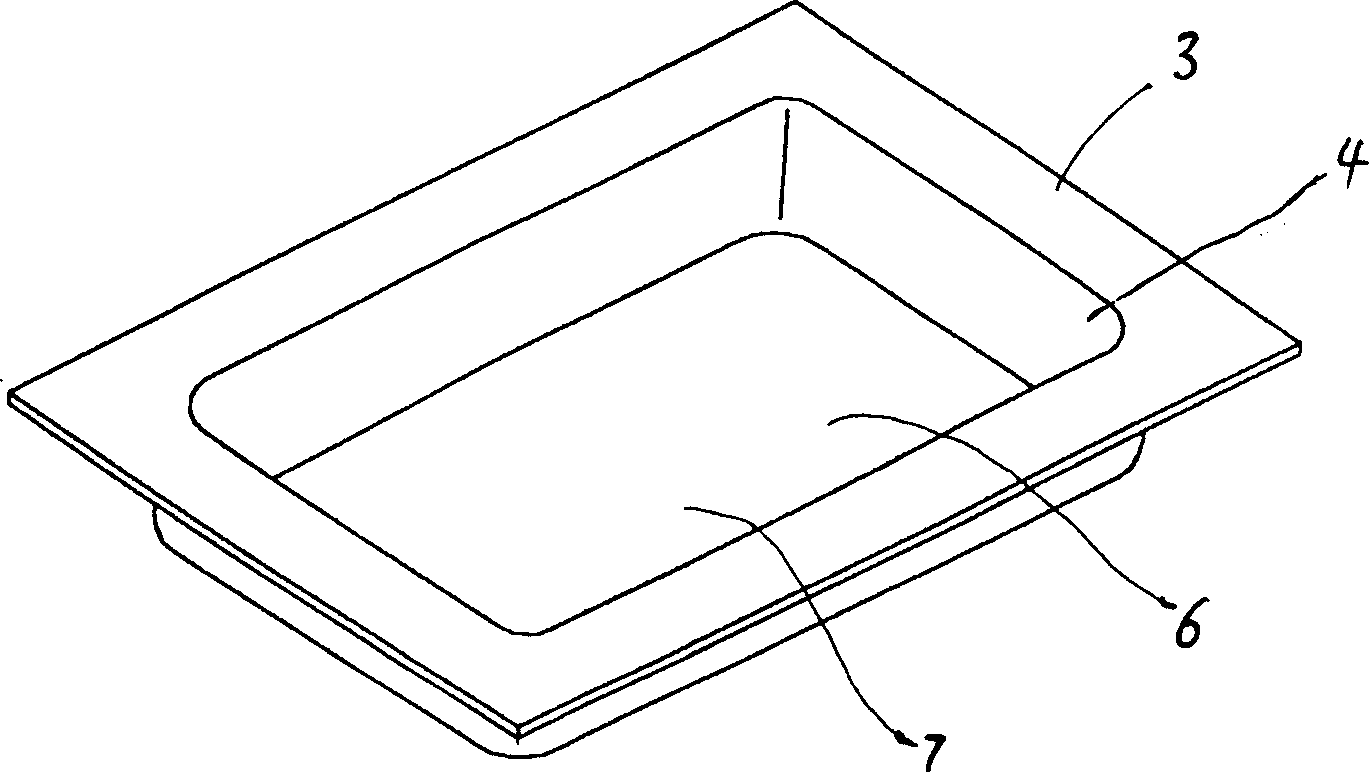

[0026] (1), the edible flour material is made into dough 1, then the dough 1 is heated and baked to a suitable hardness, molded through molds 2 and 5, to obtain the bottom box 4 and the loam cake 21 of the fast food box;

[0027] (2), pour the rice with suitable viscosity into the container and cook until the rice 11 has an appropriate viscosity, then put the rice 11 into the molding dies 9 and 12, and then extrude and form the extruded rice. The shape of the rice 10 is the same as that of the accommodating area 6 of the bottom box 4, and its size is slightly smaller than the accommodating area 6 and can just be placed in the accommodating area 6. In the middle of the formed rice 10, there is also an extruded portion for holding vegetables. 16 hollow chambers 8;

[0028] (3), grind the garlic as the egg liquid antiseptic liquid into mud, then mix it with the egg white evenly to obtain the anti-leakage liquid;

[0029] (4), the anti-leakage liquid is attached on the wall 1 aro...

Embodiment 2

[0032] (1), the edible flour material is made into dough 1, then the dough 1 is heated and baked to a suitable hardness, molded through molds 2 and 5, to obtain the bottom box 4 and the loam cake 21 of the fast food box;

[0033] (2), pour the rice with suitable viscosity into the container and cook until the rice 11 has an appropriate viscosity, then put the rice 11 into the molding dies 9 and 12, and then extrude and form the extruded rice. The shape of the rice 10 is identical to the shape of the accommodation area 6 of the bottom box 4 of the fast food box, and its size is slightly smaller than the accommodation area 6 and can be placed in the accommodation area 6. Hollow cavity 8 for containing dish material 16;

[0034] (3) Grind the garlic as the egg liquid antiseptic solution into mud, then mix it with the egg white evenly to obtain the anti-leakage liquid; garlic paste is an antiseptic material, which can prevent the protein from rotting in a short time;

[0035] (4)...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap