Means and method for heating

A heating furnace and heat technology, applied in the direction of electric furnace heating, furnace heating elements, lighting and heating equipment, etc., can solve the problems of efficiency reduction and achieve the effect of energy saving and rapid heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

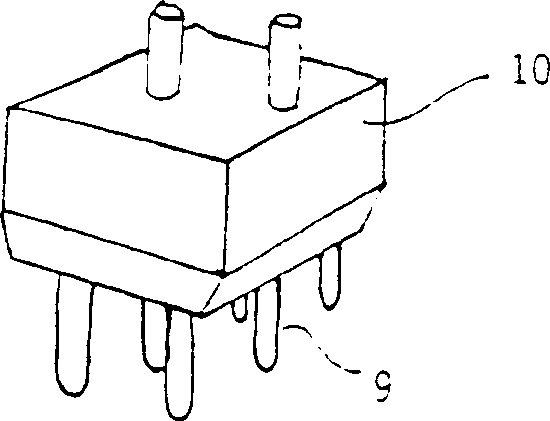

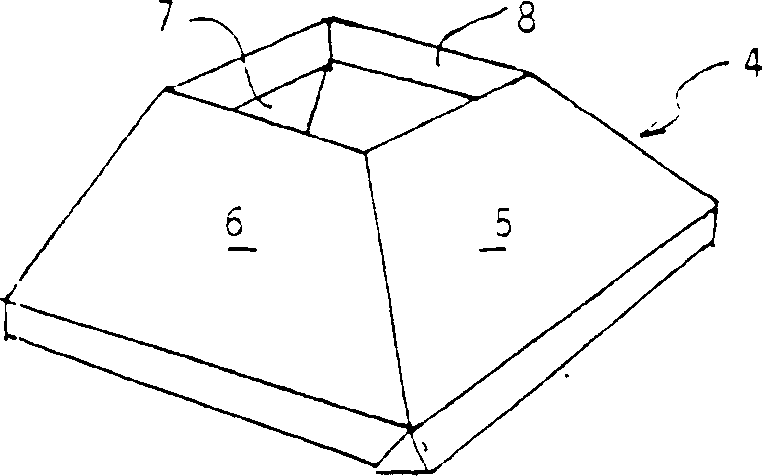

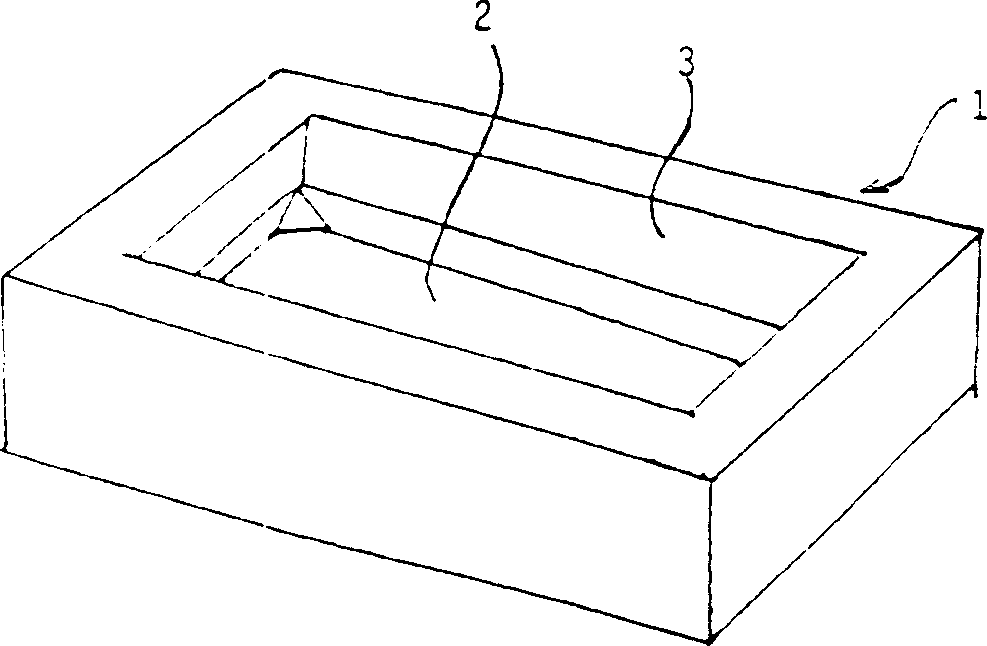

[0019] A heating device according to the principles of the present invention comprises Figure 1-5 components shown in . The main parts consist of a bottom part 1 in which the blank to be heated is placed. The bottom part has a bottom surface 2 which is surrounded by raised peripheral edges 3 which form the four side walls of the bottom part. The blank is preferably placed on some type of support so that heat radiation can be reflected by the bottom surface of the bottom part to the underside of the blank. Afterwards, one or more top pieces 4 are placed to cover the bottom piece. The side walls 5, 6, 7, 8 of the top part are inclined so that the facing side walls extend inwardly towards each other. At the uppermost point of the top part, one or more radiating elements are arranged, which extend in the space formed by the sloping side walls. The radiating element is mounted in the holder 10 and forms an assembly therewith. A preferred configuration is that the radiating el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com