Printing method of hot printing head

A thermal printing head and printer technology, applied in the field of grayscale printing, can solve the problems of wasting time and increasing production costs, and achieve the effects of improving color resolution, saving time and improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

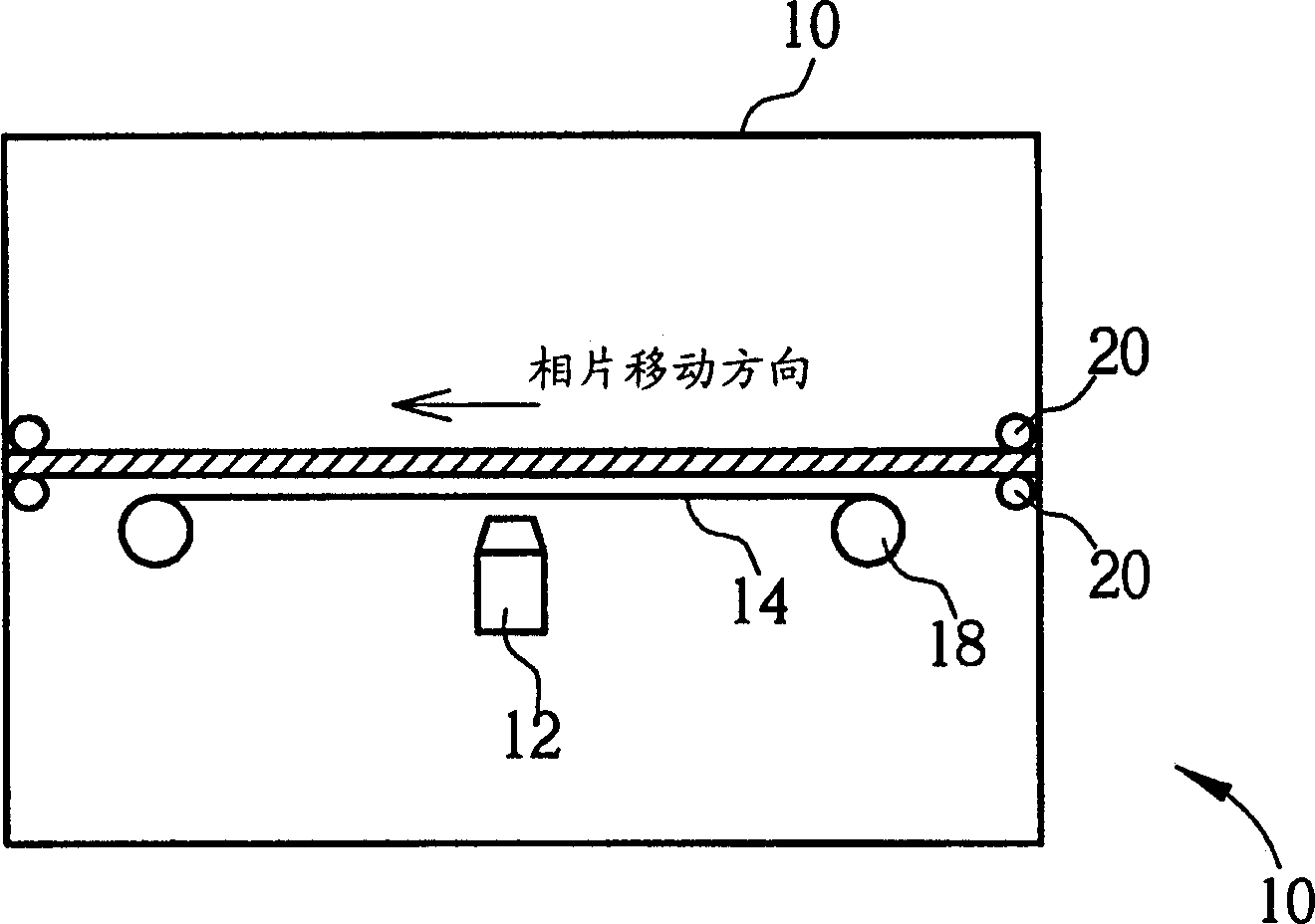

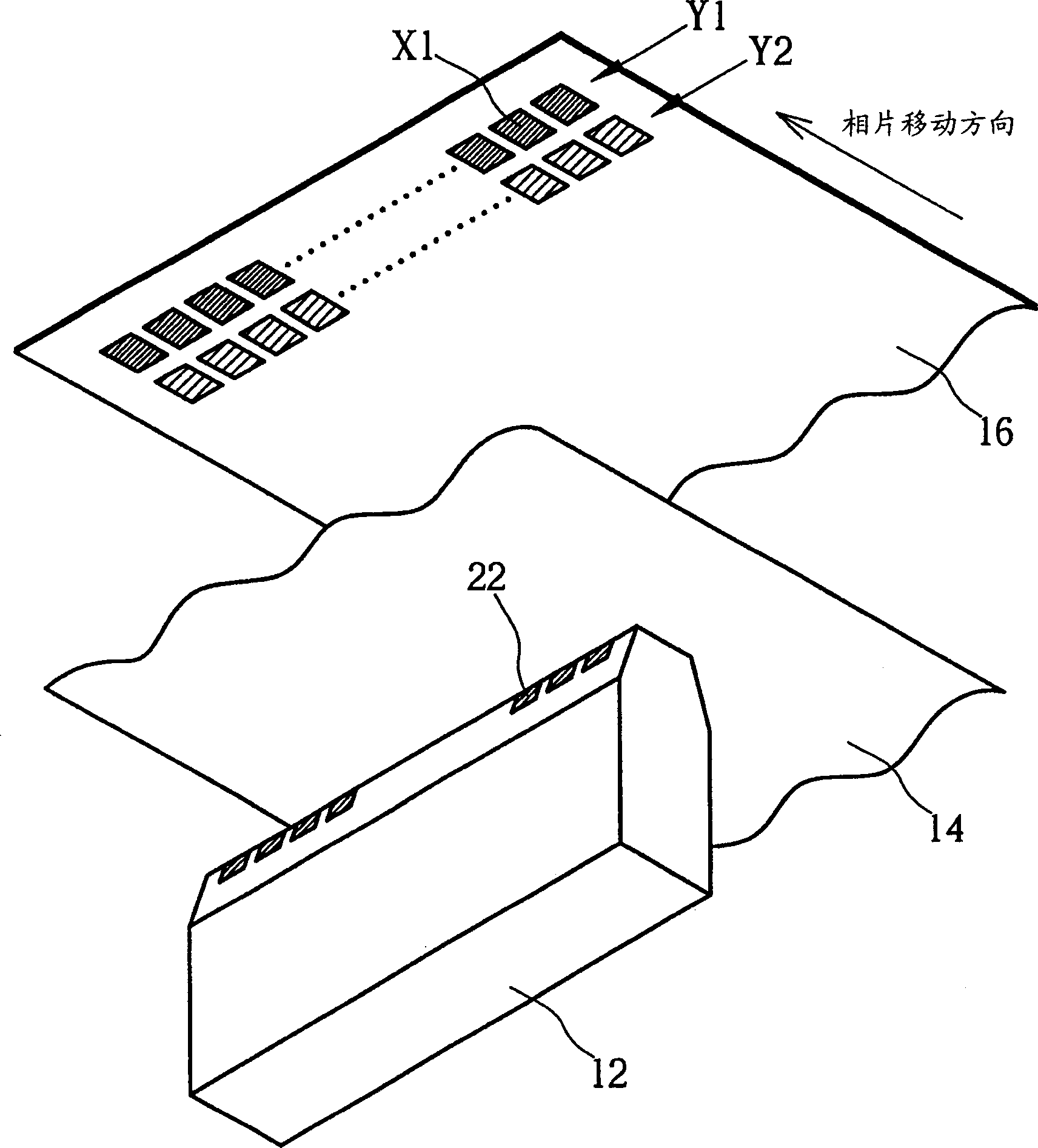

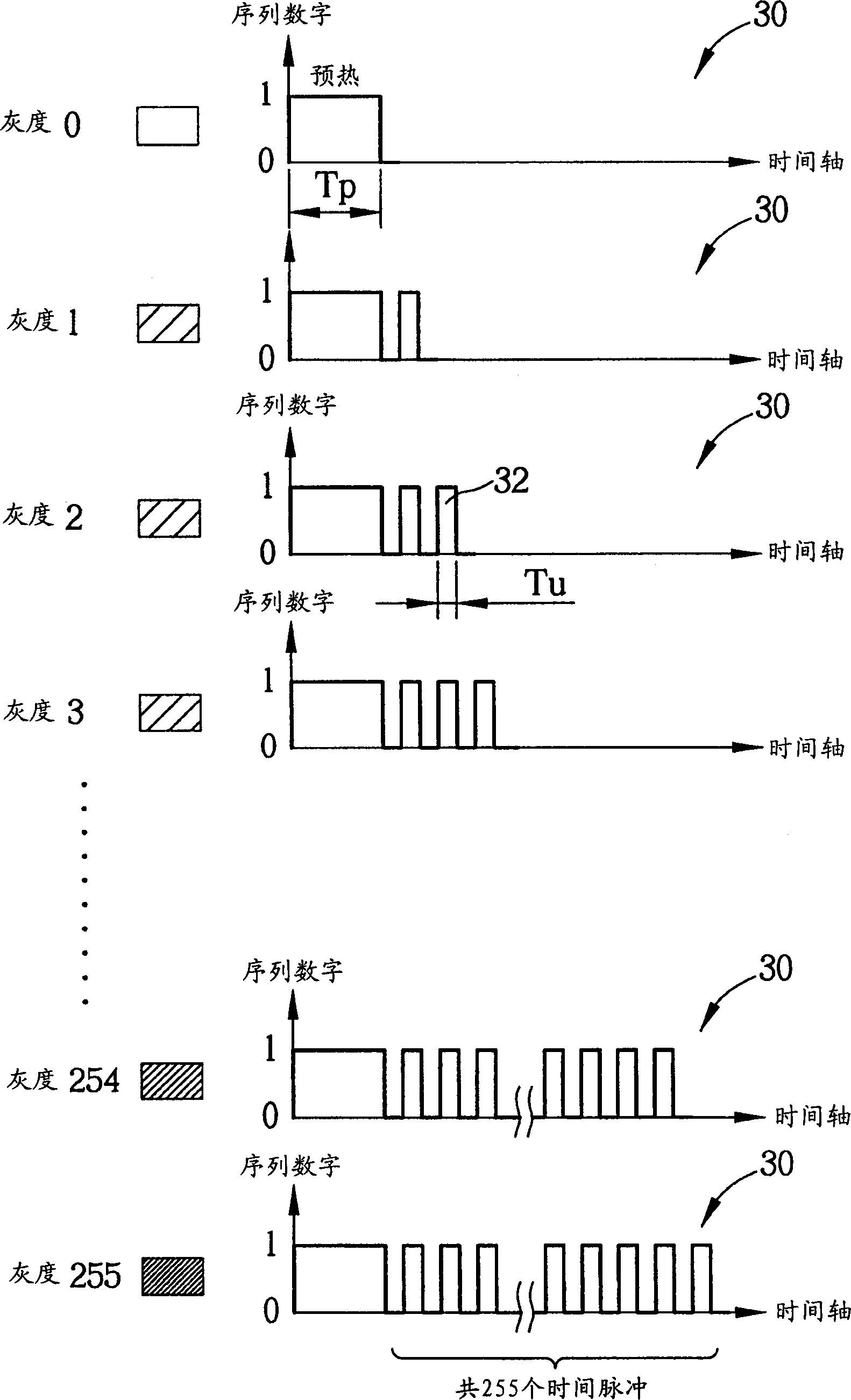

[0018] The photo printer of the present invention and the structure of thermal printing head and printing feeding mode and figure 1 and figure 2 The prior art shown is the same, so the description will not be repeated. As previously described, before the thermal print head of the photo printer of the present invention prints a photo paper, a plurality of heaters on the thermal print head can be turned on simultaneously (the digital signal value of turning on the heater is "1", and the heater is turned off. digital signal value of "0") a predetermined time Tp so that all the heaters of the thermal print head reach a predetermined temperature, which is the preheating stage, and then, according to the number of multiple line images on the photo paper The number of gray scales required for a corresponding print dot X2 is used to continuously turn on multiple heaters on the thermal print head.

[0019]Since the length of heating time of each heater can be represented by a time p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com