High-color-contrast resin lens

A high-contrast, resin lens technology, applied in glasses/goggles, instruments, optical components, etc., can solve the problem of poor color contrast of the lens, achieve the effect of improving color resolution, reducing visual fatigue, and improving color saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

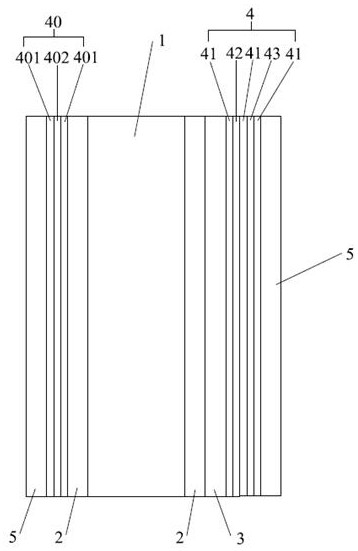

Image

Examples

Embodiment 1

[0022] Embodiment 1: By weight percentage, the monomer for producing substrate 1 consists of the following components: 7% dibenzyl maleate, 10% polystyrene resin, 45% diallyl terephthalate, containing bromine Ether 38%, add special UV absorbers UV585 and UV485 in proportion to the monomer, the ratio of monomer to absorber UV585 is 100:0.08, and the ratio of monomer to absorber UV485 is 100:0.08, so as to obtain high contrast substrate.

[0023] A monomer preparation process for high-color-contrast resin lenses: take dibenzyl maleate, styrene, diallyl terephthalate and bromoether according to the required weight ratio, mix and stir evenly, and then add dissolved The absorbers UV585 and UV485 are heated, mixed and stirred, and after cooling, the initiator azobisisobutyronitrile is added, stirred and degassed to complete the injection molding, and then put into the oven. Raise from 30°C to 70°C, keep warm for 4-10 hours, rise from 70°C to 120°C within 2-5 hours, keep warm for 2-...

Embodiment 2

[0024] Embodiment two: by weight percentage, the monomer of producing substrate 1 is made up of following components: dibenzyl maleate 10%, polystyrene resin 12%, diallyl terephthalate 44%, bromine Ether 34%, add special UV absorbers UV585 and UV485 in proportion to the monomer, the ratio of the monomer to the absorber UV585 is 100:0.09, and the ratio of the monomer to the absorber UV485 is 100:0.09, so as to obtain high contrast substrate.

[0025] A monomer preparation process for high-color-contrast resin lenses: take dibenzyl maleate, styrene, diallyl terephthalate and bromoether according to the required weight ratio, mix and stir evenly, and then add dissolved The absorbers UV585 and UV485 are heated, mixed and stirred, and after cooling, the initiator azobisisobutyronitrile is added, stirred and degassed to complete the injection molding, and then put into the oven. Raise from 30°C to 70°C, keep warm for 4-10 hours, rise from 70°C to 120°C within 2-5 hours, keep warm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com