Image detection with regionalized image resolution

A technology of image resolution and image detection, applied in image communication, analysis materials, measurement devices, etc., can solve the problems of cost factor increase, installation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

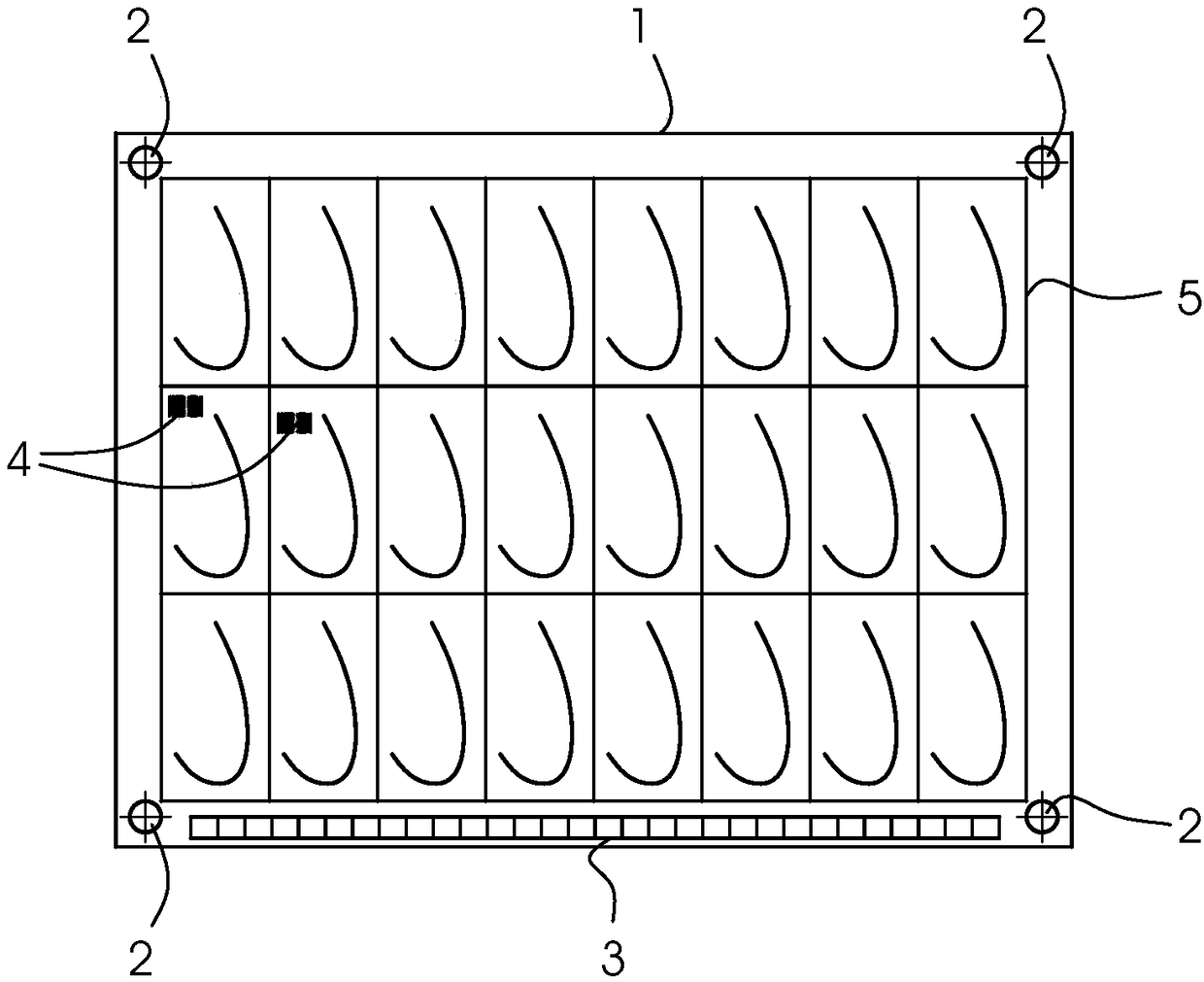

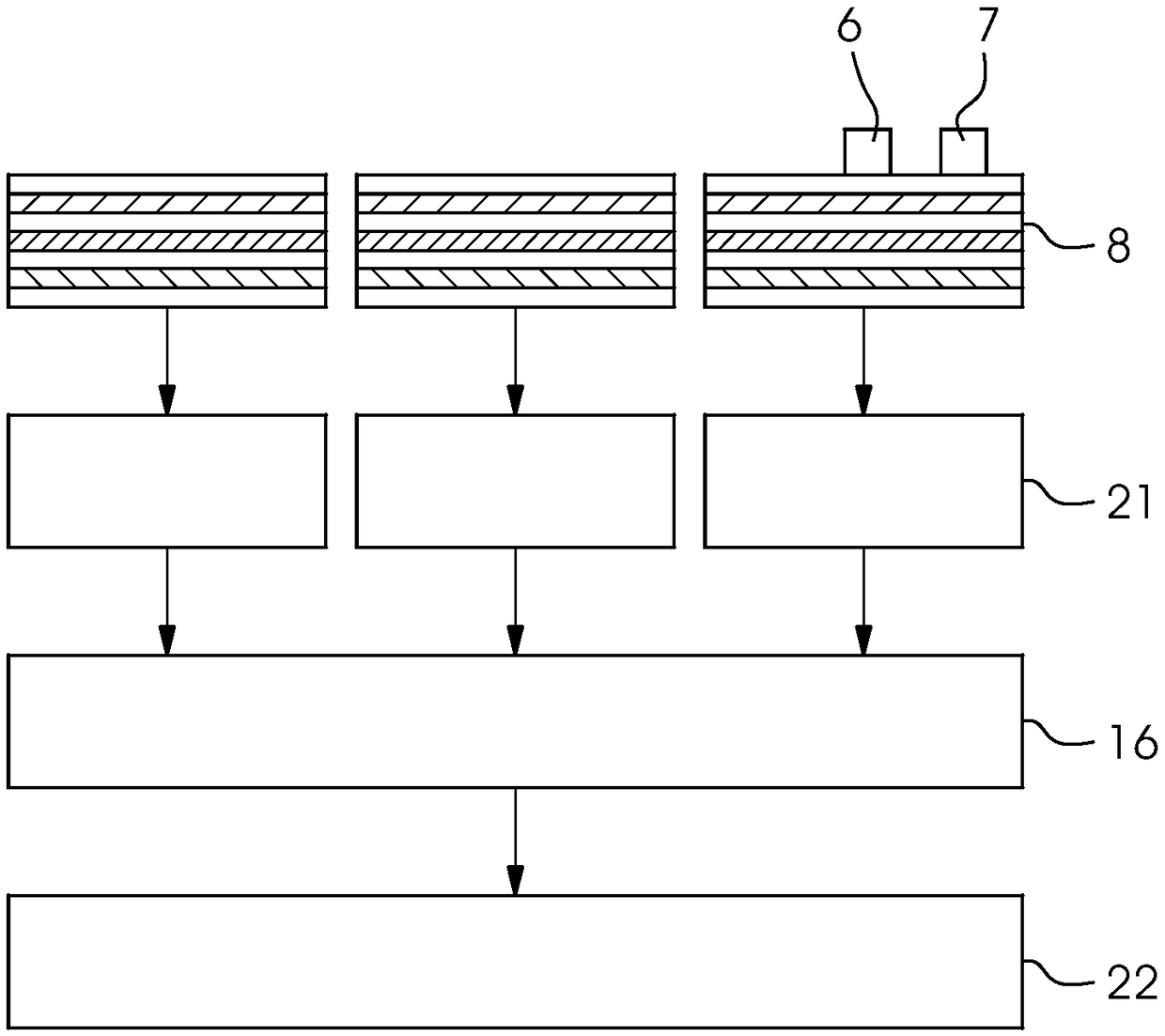

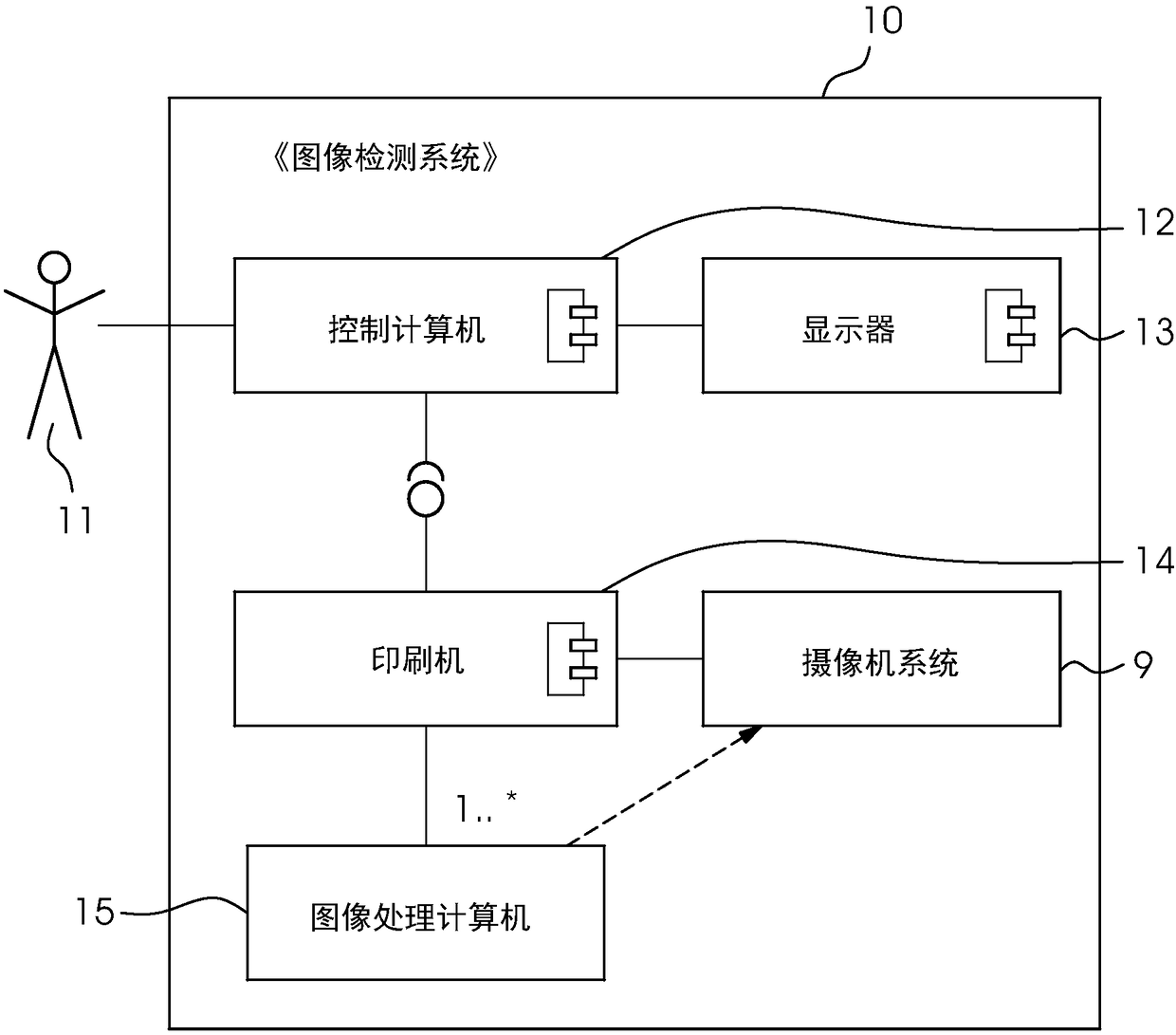

[0028] Modern image recording technologies (for example scanning strips 9 formed from CIS sensors, and CMOS cameras 9 ) have electronics that allow regionally different actuation of the image detection sensors. This property can be used to regionally vary the resolution at which the image data are transmitted to the attached image processing system, depending on the function (register measurement, image detection or color measurement). Internally, the sensor always operates at the highest resolution, however, this data is aggregated to the desired resolution in the electronics of this proximity sensor. This can be achieved not only in row direction but also in column direction by averaging several rows of image pixels. The scanning strips 9 comprise a plurality (>100) of assembled sensor modules which can be actuated independently. These single sensor modules can also operate at high speeds (>5m / s) with high image resolutions (600dpi).

[0029] In principle, these RGB scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com