Light tube for filling bidirectional-rib steel bar reinfored concrete

A reinforced concrete, lightweight technology, applied in building components, floors, buildings, etc., can solve the problems of large difference in bidirectional stiffness, large consumption of reinforced concrete, and poor seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

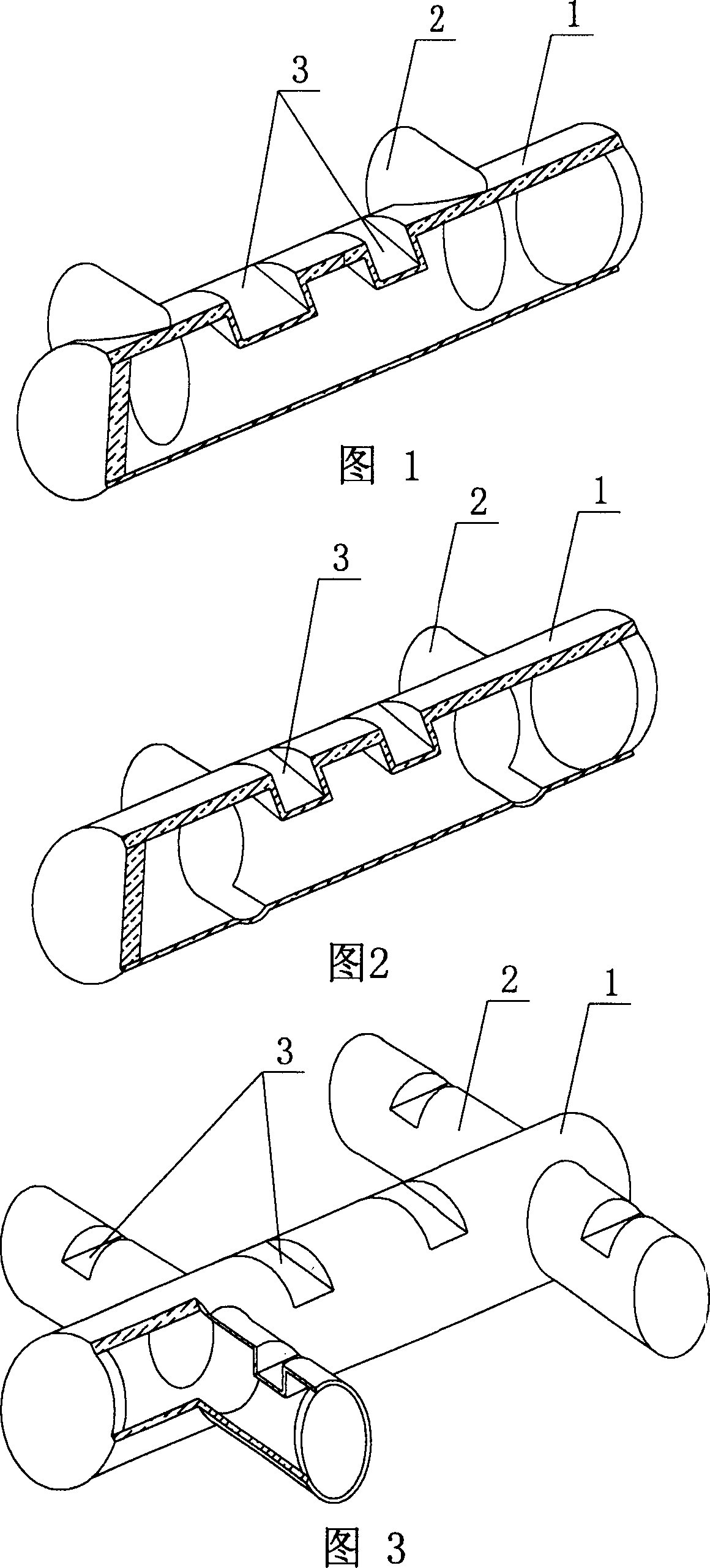

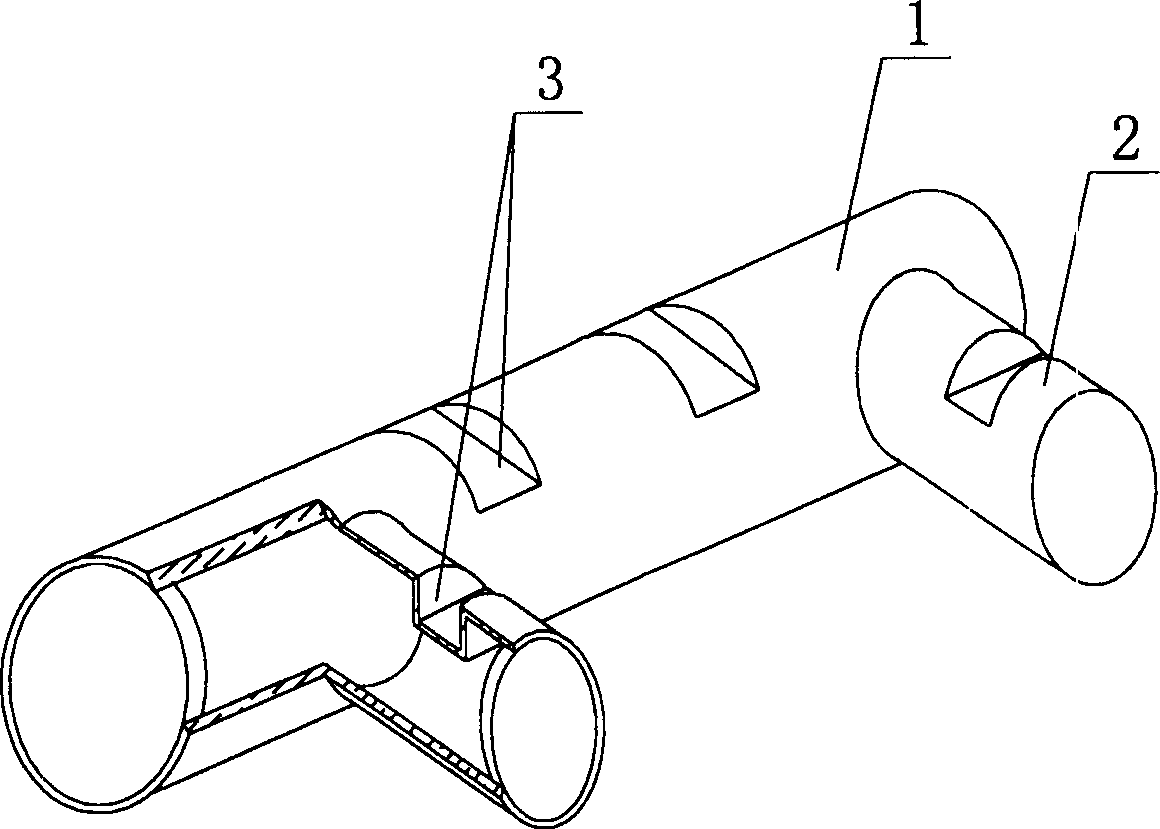

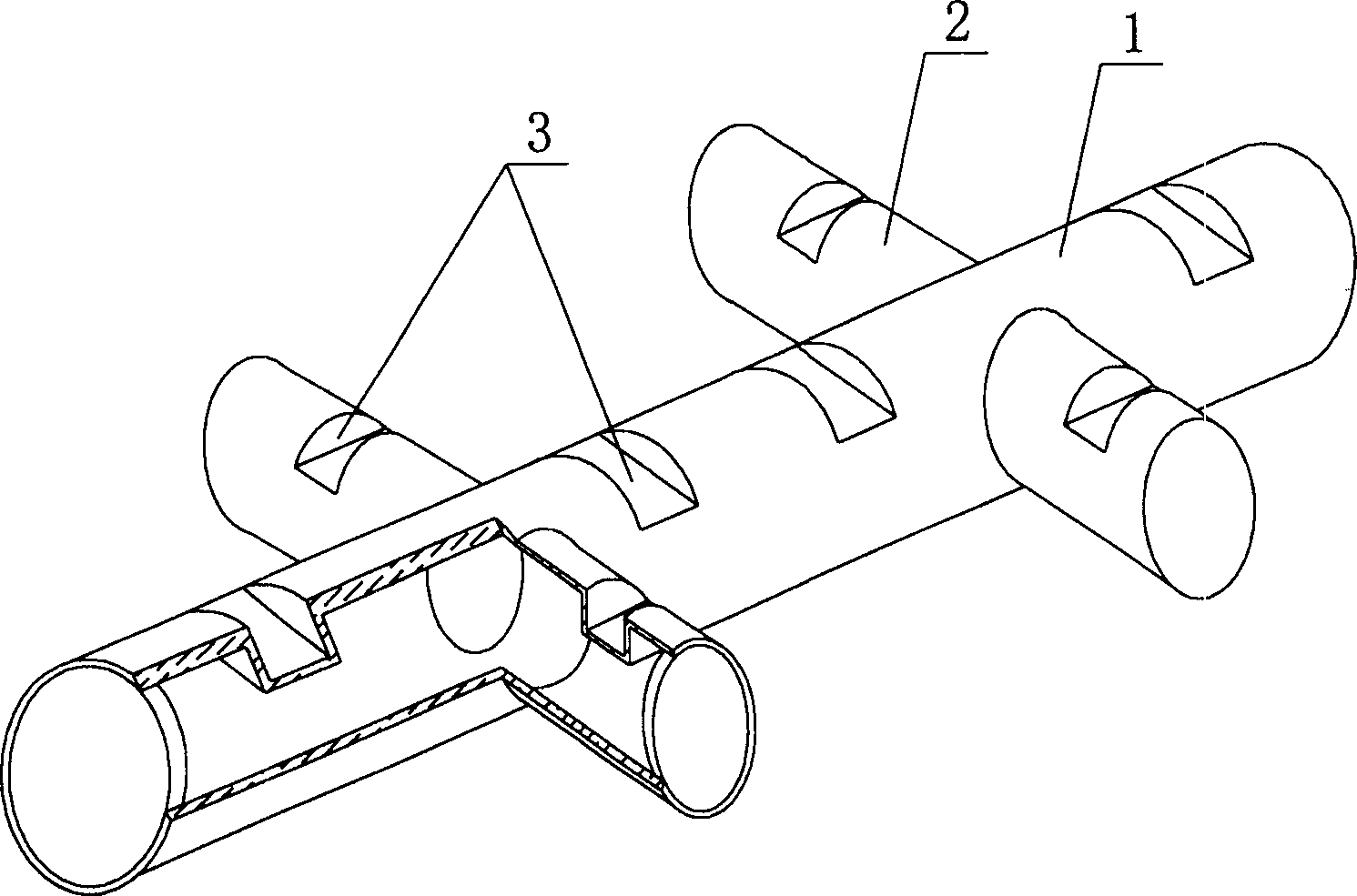

[0077] As shown in the accompanying drawings, the present invention includes a longitudinal pipe body 1, which is characterized in that at least one transverse pipe body 2 protrudes from the longitudinal pipe body 1, and at least one transverse groove 3 is provided on the longitudinal pipe body 1. Fig. 1 is a schematic structural diagram of Embodiment 1 of the present invention. Among Fig. 1, 1 is a vertical pipe body, 2 is a horizontal pipe body, and 3 is a groove. In the following drawings, those with the same numbering have the same description. In FIG. 1 , a horizontal tube body 2 protrudes from the vertical tube body 1 , and a transverse groove 3 is arranged on the vertical tube body 1 .

[0078] The present invention is also characterized in that the tube bottom surface of the horizontal tube body 2 is recessed in the tube bottom surface of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com