Yarn quality and component detecting method and device

A technology of yarn quality and detection device, applied in the direction of measuring device, tension measurement, using optical device, etc., can solve the problems of unable to reflect the composition ratio of blended yarn, unable to reflect the true color unevenness of yarn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

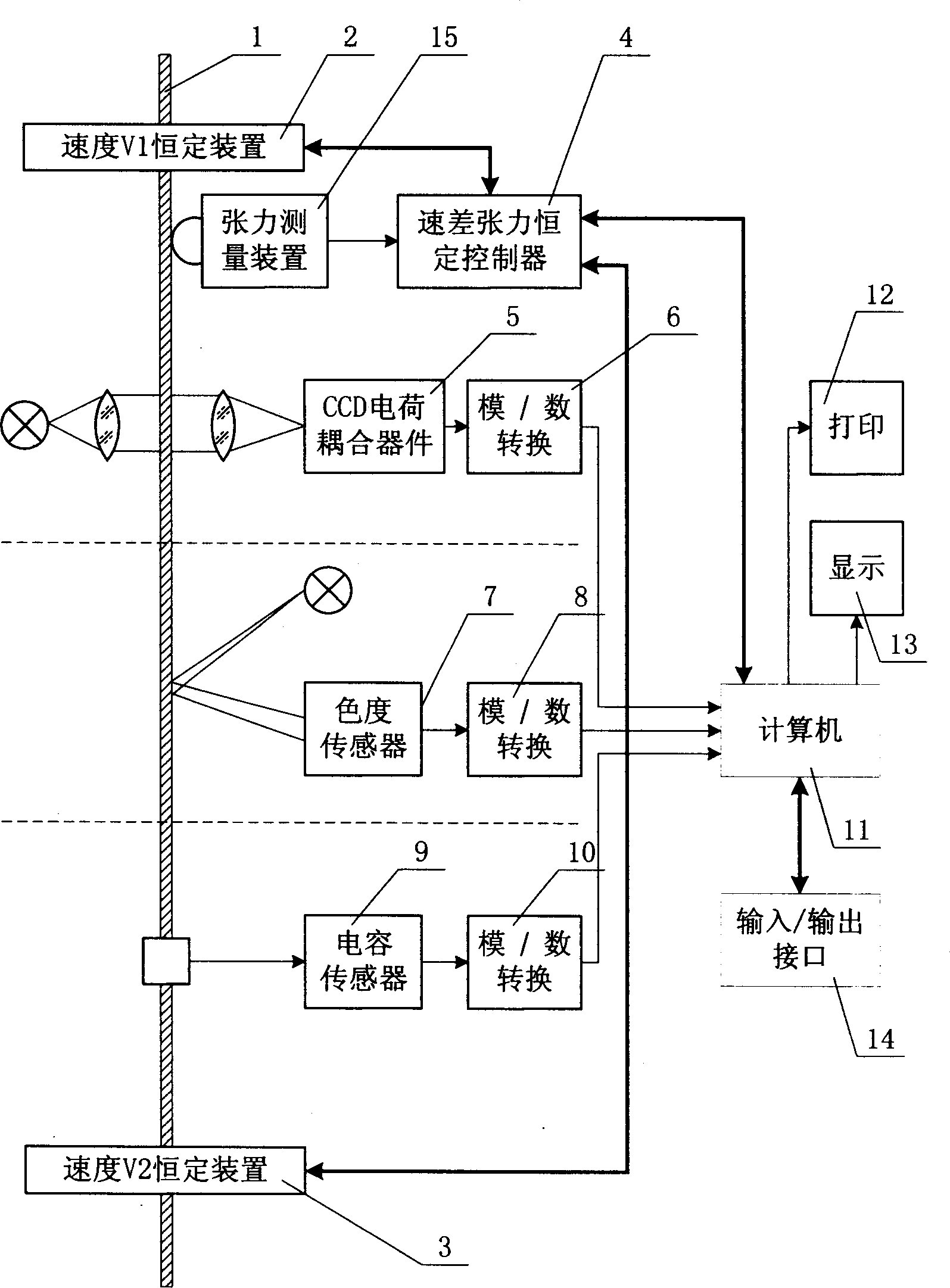

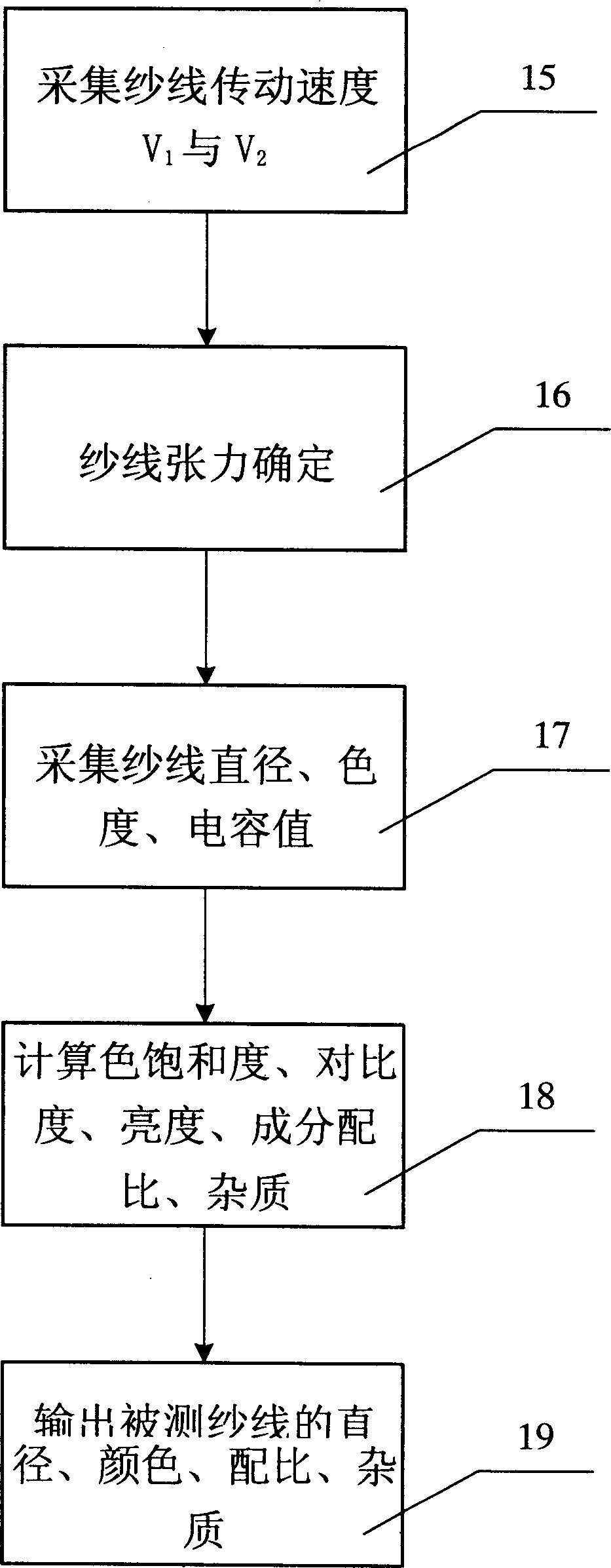

[0016] The inventors of the present invention recommend the following examples. Please refer to the accompanying drawings, this embodiment is carried out according to the clear technical solution in the summary of the invention. Yarn under test 1 by speed V 1 Constant device 2 and speed V 2 Constant device 3, both of them maintain the speed of one end of yarn 1 as V 1 , the other end is V 2 In this way, the yarn is kept moving under a certain tension, and the speed signals of the two are sent to the speed difference tension constant controller 4, and the tension is calculated, and the speed difference tension constant controller 4 feeds back the signal to the second speed constant The yarn speed is maintained, and the yarn speed data and tension data are sent to the computer 11, and the computer 11 also instructs the constant speed differential tension controller 4 when necessary. In the yarn segment between the two speed constant devices, three detection devices are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com