Production technology of tin-plated wire-drawing die slip-in cover

A technology of production process and wire drawing die, which is applied in the direction of metal drawing forming tools, metal wire drawing, manufacturing tools, etc., can solve the problems of not being able to identify whether natural diamonds are broken, brittle, and natural diamonds are brittle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

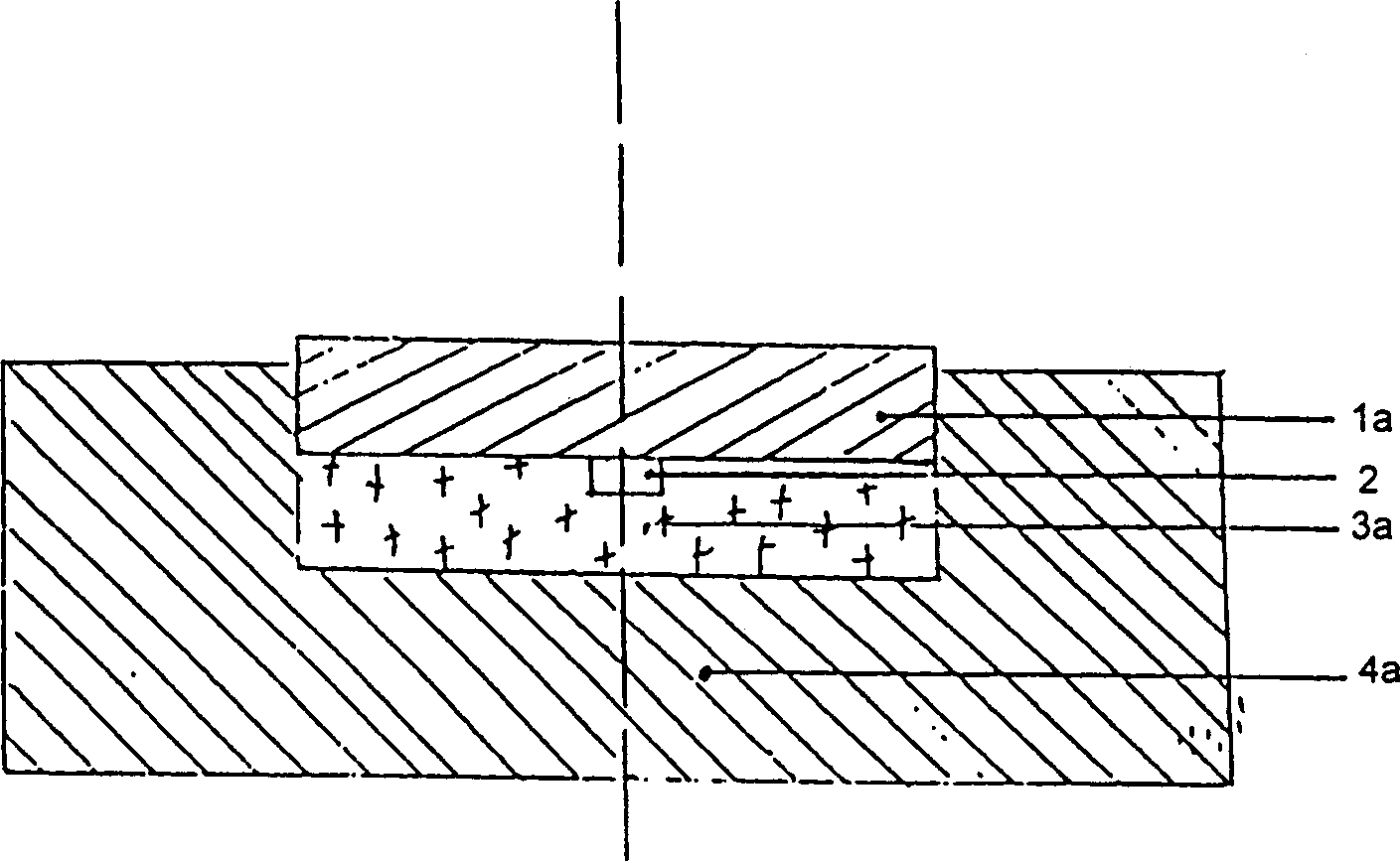

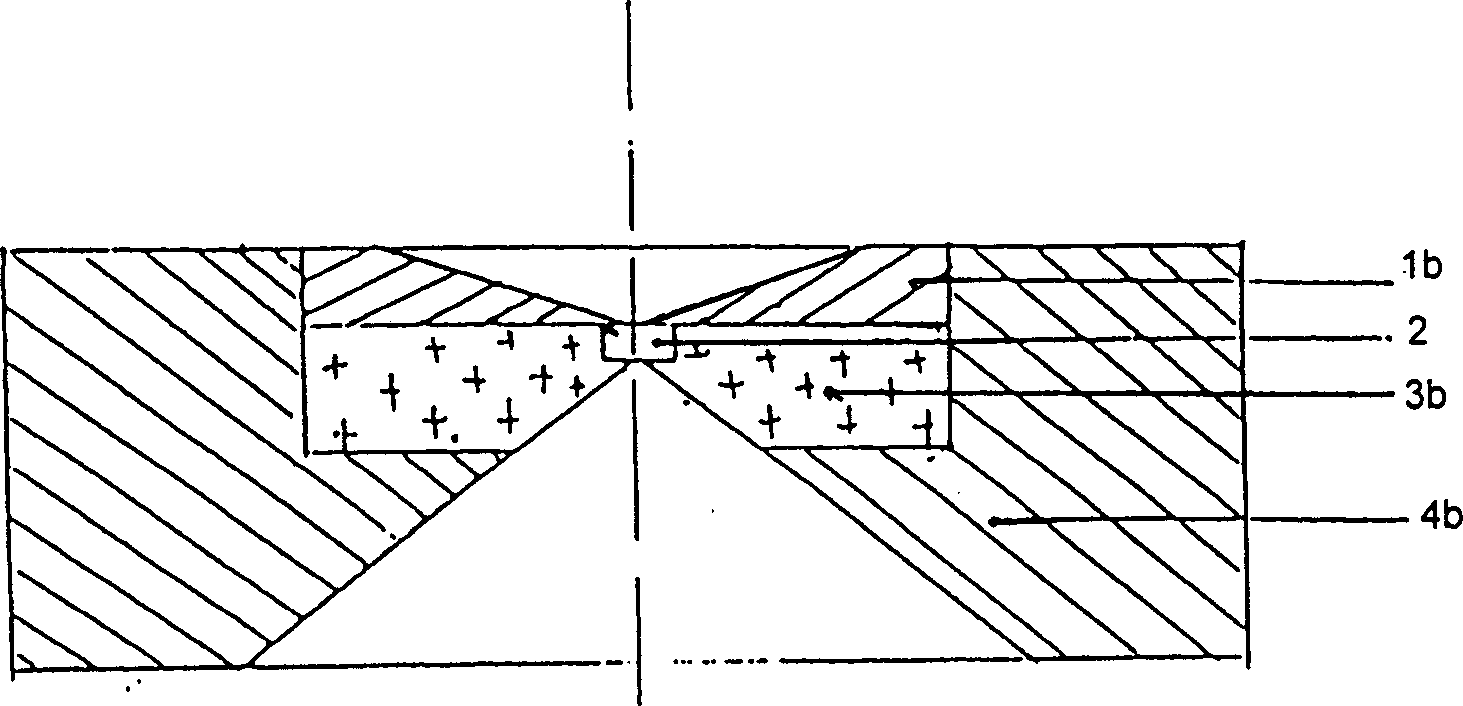

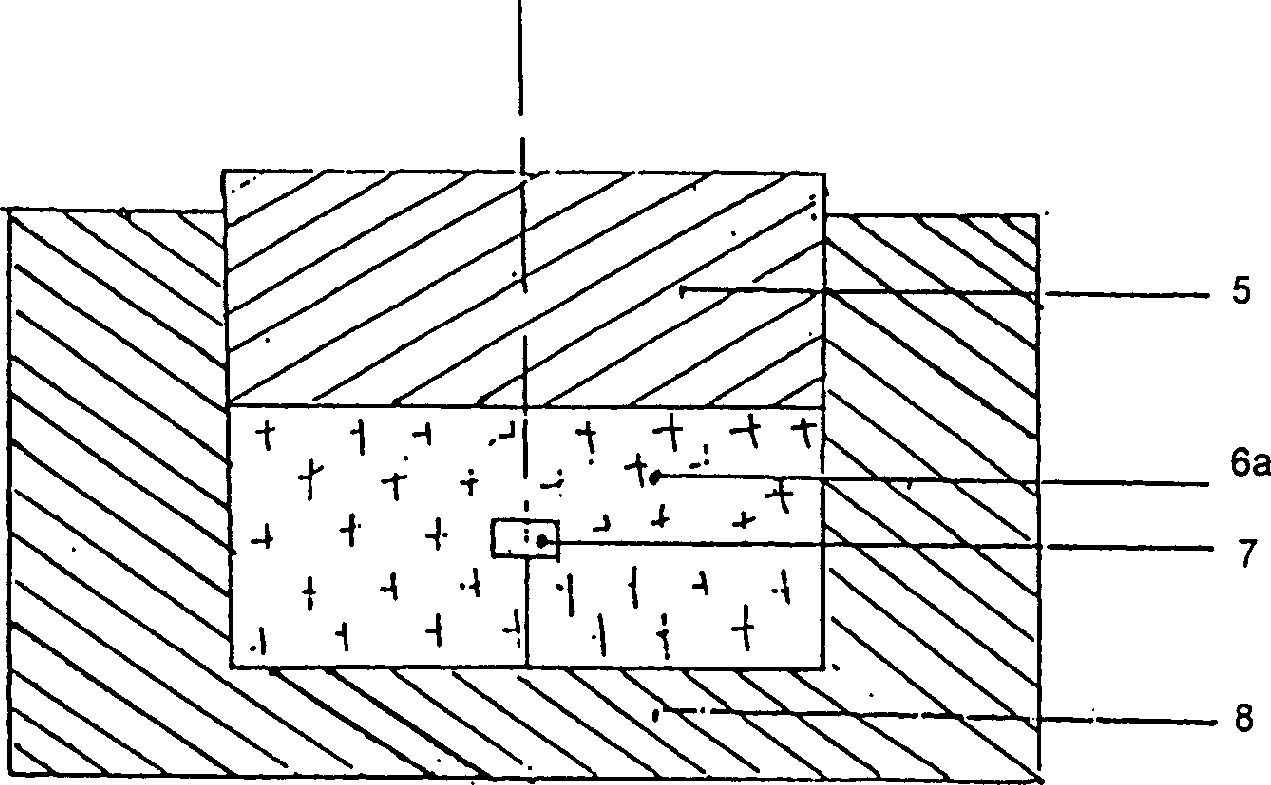

[0009] As shown in Figure 3 to Figure 6, the technological process of the tin-plated wire drawing die is to place the process mold cover 8 that has been pre-carved according to the required size on the workbench, and the process mold cover 8 is made of a material with a higher melting point than the metal powder 6a , such as 45 steel or A 3 Steel, then add metal powder 6a in process mold cover 8, natural diamond 7 is bonded to the center of standard bar plane (not shown in the figure) with glue, just insert in the metal powder 6a when glue is not dry, carry out cooling subsequently Pressure (7.5kg / cm 2 ). After the standard rod is gently unscrewed, metal powder 6a is added to the hole, and the mold core 5 is covered on the metal powder 6a (as shown in Figure 3) and then cold pressed (15kg / cm 2 ), the mold core 5 is selected from a material with a higher melting point than the process die sleeve 8, such as stainless steel. Put the finished model on the heating equipment to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com