Method for calibrating industrial CT system detector by group series winding

A correction method and a detector technology, which are applied in digital differential analyzers, calculations using non-numerical representations, material analysis using radiation, etc., can solve problems such as inaccurate data correction, slow correction speed, and slow convergence, and achieve Effects of increased computation time, good calibration quality, and fewer iterations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

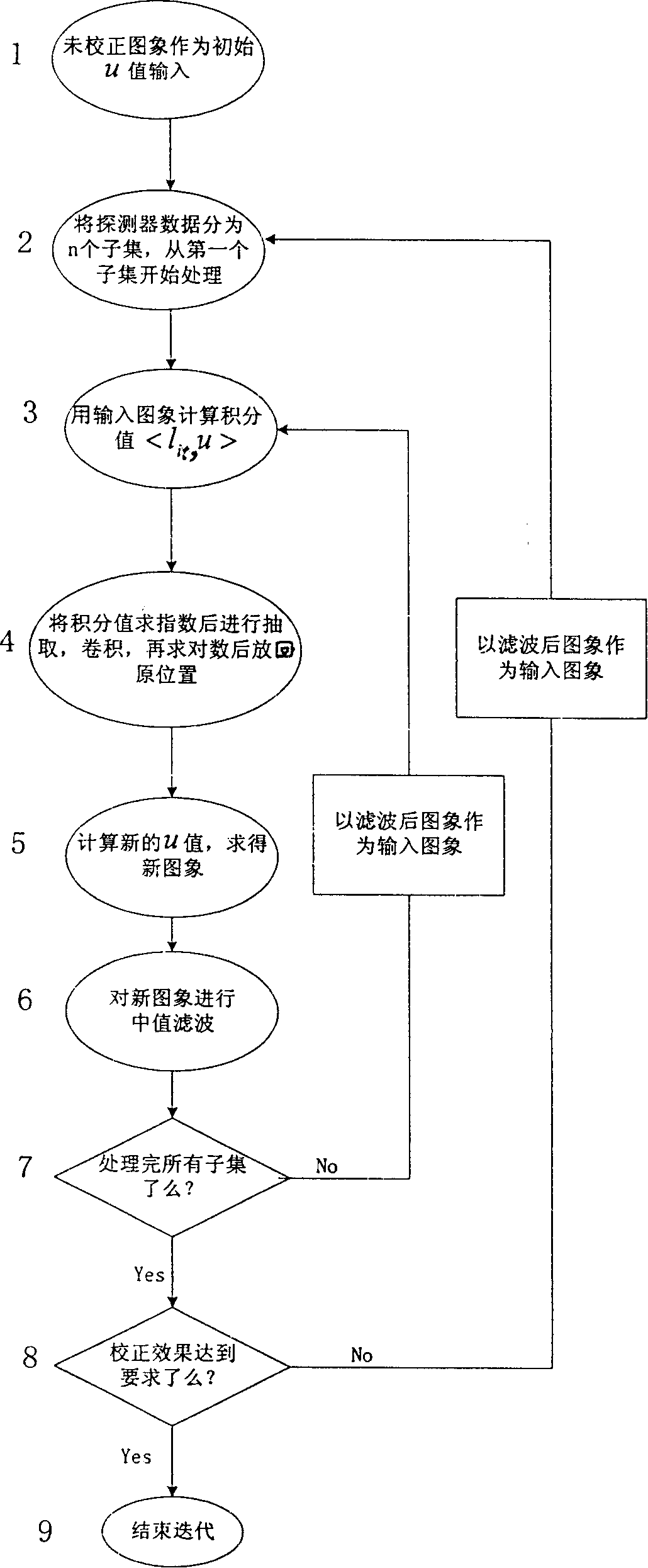

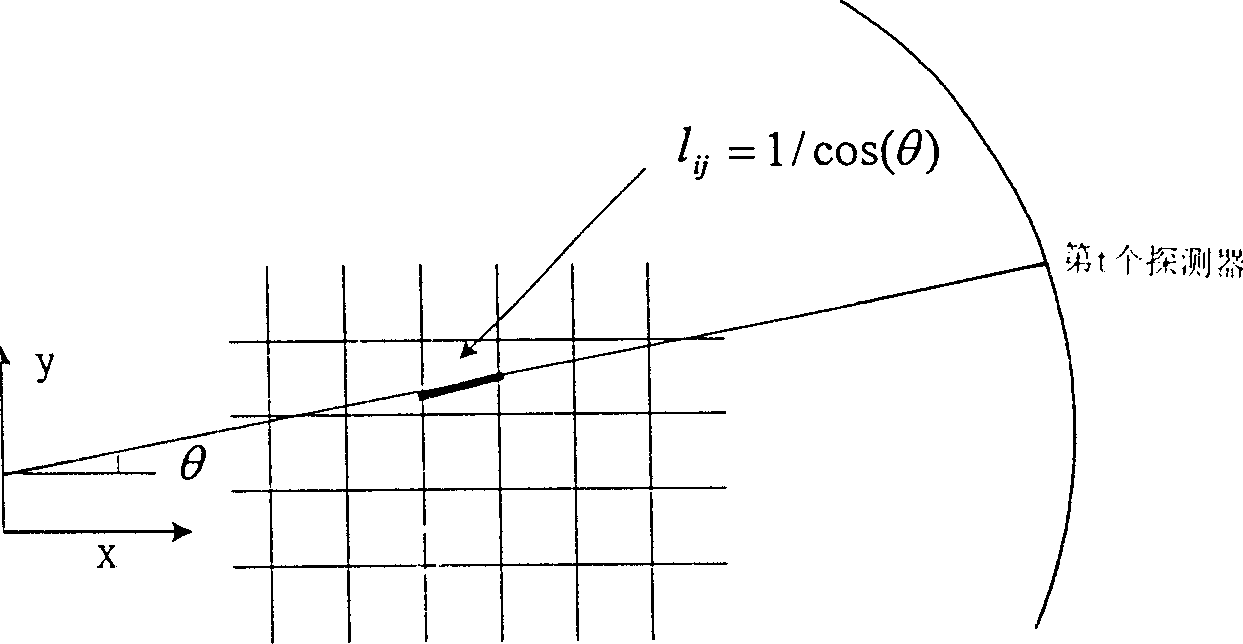

[0025] For the step (3) of the technical solution, the specific method for calculating the integral value with the input image is: set the number of subsets as s, and input the absorption coefficient u in a certain projection direction i j Calculate the integral value in each detector direction t l it , u > = Σ j l itj u j , Where l itj Is the intersecting length of pixel j in the direction of t detector when pixel j is in the projection direction of i; t = 1, 2, ..., k is the number of detectors in each scan, calculate all integral values for t, it , u>, Repeat the above steps for all i in the subset, and calculate all the integral values ti , u>, I=(s-1)*r / n+1,...,s*r / n. The intersection length l itj Can be calculated approximately (see figure 2 ), the specific method is: if the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com