Method for casting cast or enclosed casting part and device for carrying said method

A technology for parts and castings, applied in household components, household appliances, other household appliances, etc., can solve problems such as dependence and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

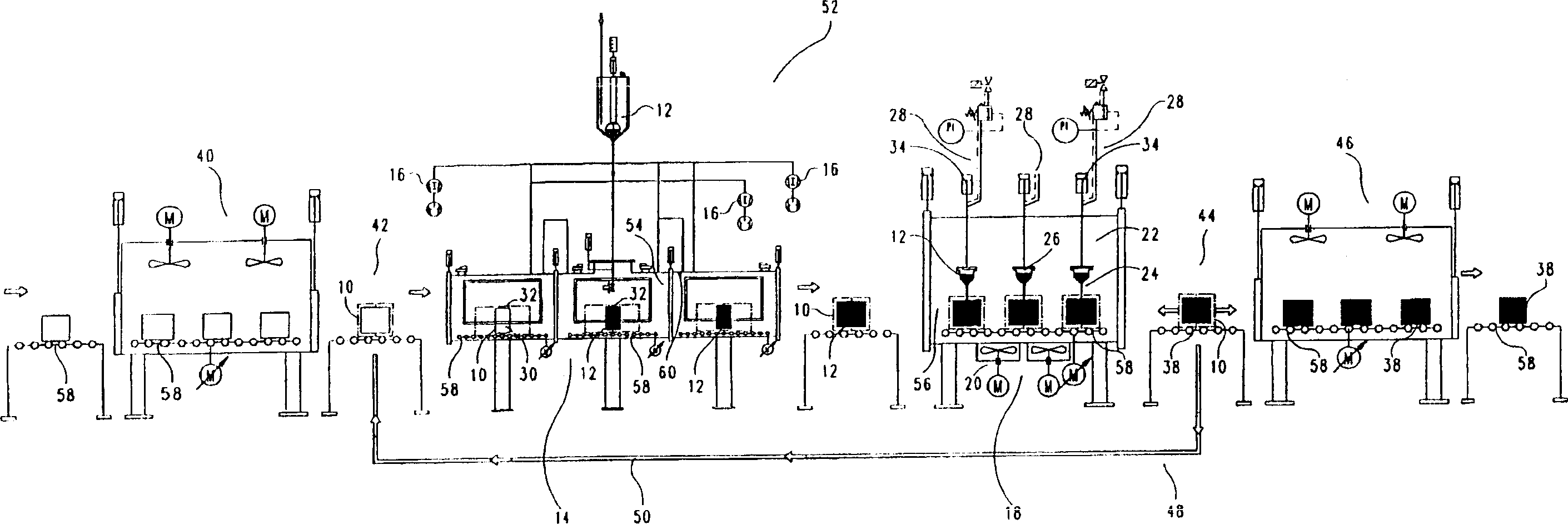

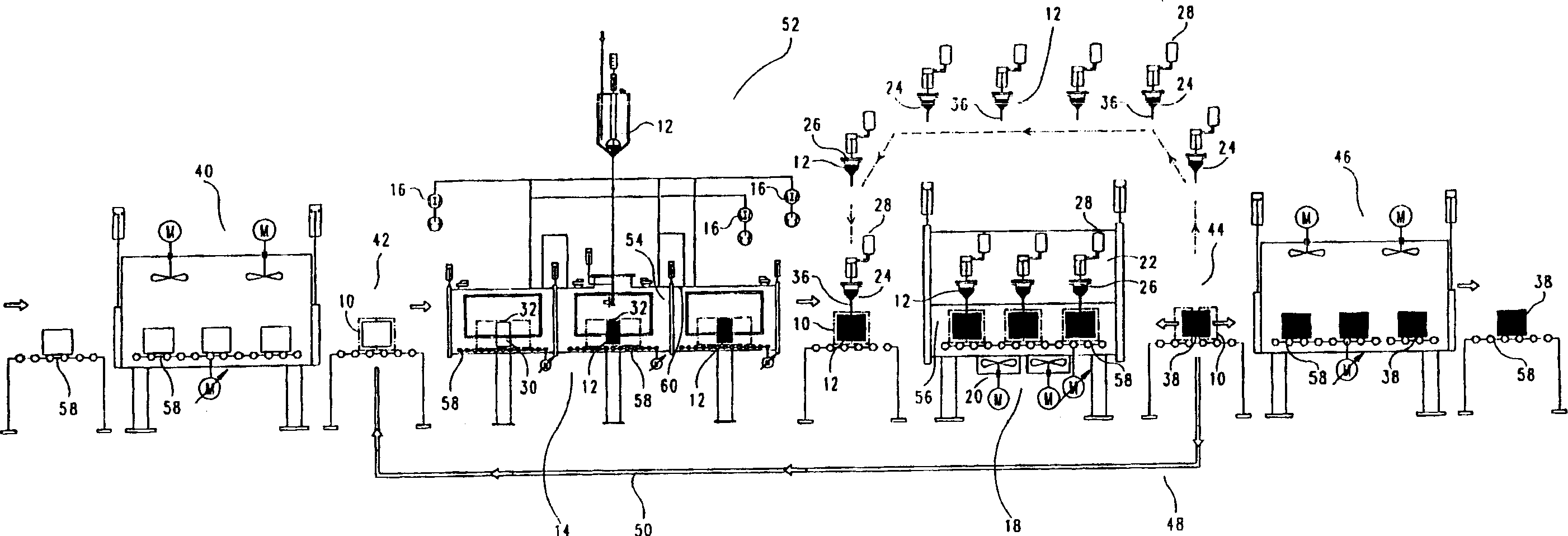

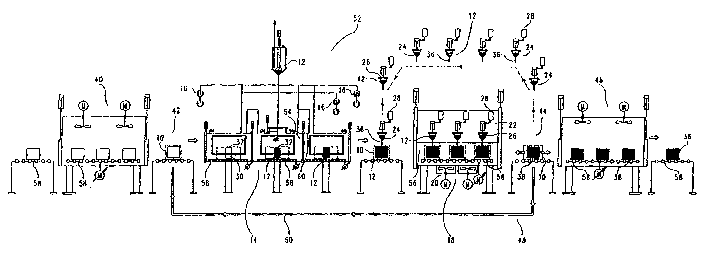

[0049] exist figure 1 and 2 The device 52 shown in represents a preferred embodiment for carrying out the method. Apart from the coagulation furnace 56 , the device 52 is designed essentially the same or similarly.

[0050] The casting mold 10 is conveyed through the device 52 by means of a conveying device 58 . In this case, a preheating station 40 , an assembly station 42 , a casting chamber 54 , a coagulation furnace 56 , a demolding station 44 and a hardening station 46 are connected in succession. From the demolding station 44 the casting molds can be conveyed back to the assembly station 42 via a cleaning station 48 and a return station 50 in the form of a loop.

[0051] After possible preheating in the preheating station 40 , the casting mold 10 is transported to the assembly station 42 by means of the conveying device 58 , so that—if necessary with the components to be poured—it can be assembled into a multi-cavity casting mold 10 . The casting mold 10 is then tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com