Screen printing original plate, processing method for print plate and screen printing method

A technology of screen printing and processing method, applied in screen printing machine, printing process, printing and other directions, can solve the problems of poor size reproducibility, too fine ink dots, and difficulty in satisfying image characteristics at the same time, and the method is not complicated. , the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

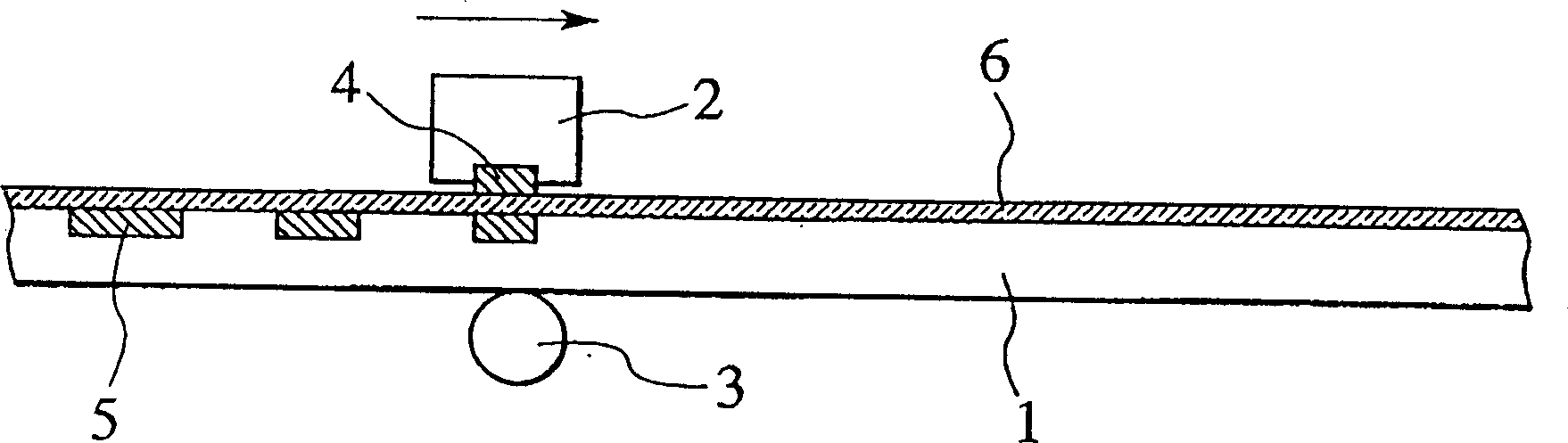

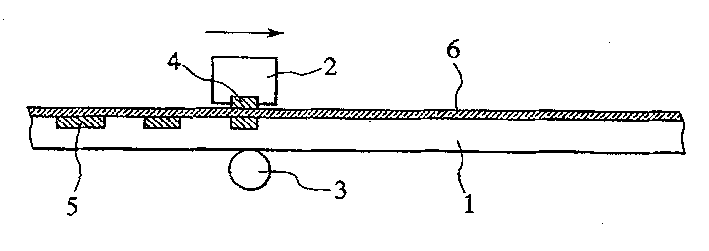

Image

Examples

example

[0099] The present invention will be described in more detail through examples as follows, but the present invention is not limited by these examples without departing from the technical idea of the present invention. For example, the resolution and type of the heating head may also be different from the resolution and type described herein. The types and regulations of materials, such as release agents, are more likely to be different from those described.

[0100] In addition, the measurement and evaluation described in the examples are performed in the following method.

[0101] (1) Printing plate processing method

[0102] First, for each screen printing original plate (hereinafter referred to as the original plate) prepared in each example and comparative example, a contact surface with a heating head, that is, a porous resin film coated with a wire-drawing spindle contains 5 parts Weight of polyether modified silicone resin oil (TSF400, product name of GE Toshiba Silicone ...

Embodiment 1

[0139] (Preparation of resin mixed solution)

[0140] Resin: 100 parts by weight of water polyurethane (AdecaBon Titer-HUX-401 from AsahiDenka),

[0141] Foam stabilizer: 5 parts by weight of higher fatty acid reagent (produced by Sun Nopco Co., Ltd. named SN Foam 200)

[0142] Thickening agent: 5 parts by weight of carboxymethyl cellulose (Dai-ichi Kogyo Seiyaku's product is AG GUM).

[0143] The resin mixed solution was foamed and stirred for 25 minutes with a stirrer (product name of Aicoh Manufacturing Company, Ken Mix Aicoh PRO) at a stirring rate of 500 rpm and a foam containing the resin mixed solution with a foam magnification of 7.0 was prepared. Then, quickly change the weight to 52g / m 2 The coating amount of one layer of high-quality paper with a coating rod is 15g / m 2 The solution is dried, and the porous resin film is formed while obtaining a heat-sensitive original plate for screen printing.

[0144] Example

1

2

3

4

...

Embodiment 2

[0147] The resin mixed solution with the same structure as in Example 1 was subjected to a foaming treatment, and the same stirrer was used to stir at a stirring rate of 500 rpm for one minute to prepare a foam containing the resin mixed solution with a foam magnification of 1.1. Then quickly change the weight to 52g / m 2 Use a paint stick to coat one layer of high-quality paper with a coating amount of 15g / m 2 The solution is dried, the porous resin film is formed, and the screen-printed heat-sensitive original plate is obtained.

[0148] The average pore diameter of the porous resin film of the obtained original plate is 5.2μm, and the coating density is 0.39g / cm 2 , Its physical properties are shown in Table 1.

[0149] Similar to Example 1, after the release layer is formed on the obtained original plate, the printing plate is processed by the heating head, and printing is performed.

[0150] As a result, as shown in Table 1, satisfactory results were obtained for all hole bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com