Electrostatic actuating micro-holder

An electrostatic actuation and micro-clamping technology, which is applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of DC power consumption, application range limitations, Problems such as slow response speed of the micro gripper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

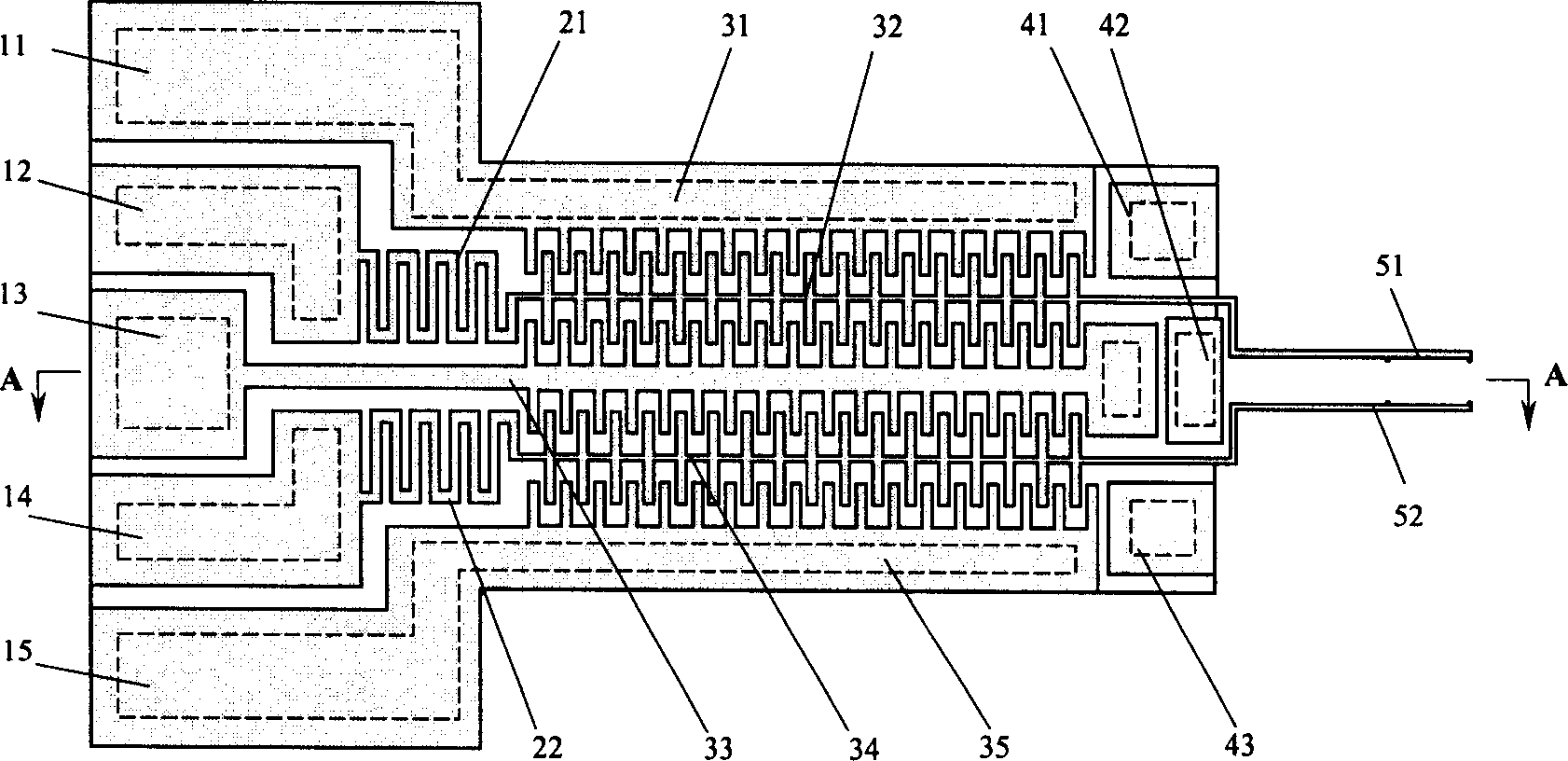

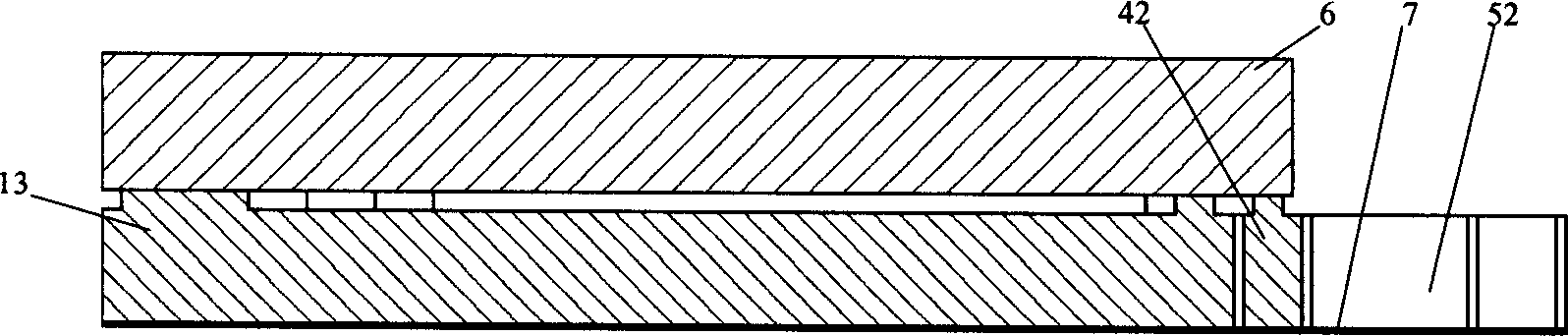

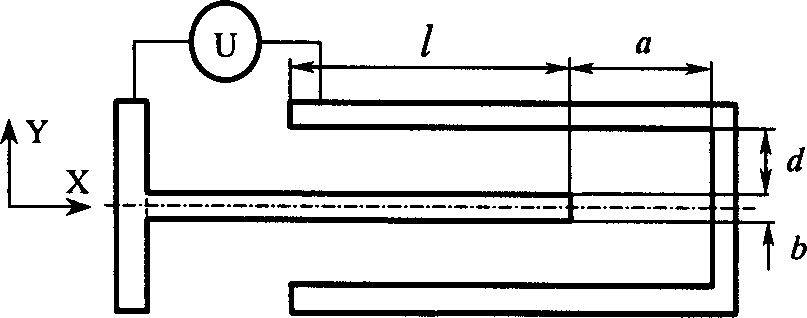

[0024] Such as figure 2 As shown, the present invention is a planar structure as a whole, consisting of driving electrodes 11, 12, 13, 14, 15, flexible structures 21, 22, moving comb teeth 32, 34, fixed comb teeth 31, 33, 35, limit blocks 41, 42, 43, micro clamping arms 51, 52, bottom plate 6, metal bonding layer 7 and other parts. Drive electrodes 12 and 14 are respectively connected to flexible structures 21 and 22, and as their fixed ends, the flexible structure is a continuous S-shaped structure; drive electrodes 11, 13 and 15 are connected to fixed comb teeth 31, 33, 35; flexible structure 21 and 22 are connected with moving comb teeth 32 and 34 respectively; Moving comb teeth 32 and 34 are respectively a part of micro-clamping arms 51 and 52; Limiting blocks 41, 42 and 43 are isolated structures distributed between micro-clamping arms 51 and 52 52 on both sides; driving electrodes (11, 12, 13, 14, 15), fixed comb teeth (31, 33, 35), and position-limiting structures (41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com